What are the Impediments that are Preventing US CHIPS Act from Boosting Chip Manufacturing

In an effort to reduce dependence on Asian countries on chip import and to revive the country’s growth in semiconductor production, the USA in August 2022, has unleashed the much-awaited CHIPS Act worth $52 billion. Since the time of Trump administration the country has been undertaking various strenuous efforts and involved in geopolitical scuffles with China to shatter the latter’s dream of leading the technology industry. The US is trying to persuade its EU allies and India to join its league of anti-China strategies and decided to craft a ‘Chip 4’ association with Taiwan, South Korea, and Japan to build a strong semiconductor supply chain that will keep out China.

In the last two decades, the share of US chip manufacturing has reduced drastically, while advanced chipset production is now largely spearheaded by a couple of countries like South Korea and Taiwan. Currently, 90 percent of the sophisticated chips, which are of great importance for the US defense and economy are manufactured in Taiwan. This has created worries about the supply’s vulnerability, given China’s plan of military invasion on Taiwan. Chipsets, which are less sophisticated but useful in electronics, cars, and other products are now produced in China whose market has also augmented exponentially. 12 percent of semiconductors are now produced in the US that are not globally advanced.

Senior Research Analyst Faisal Kawoosa, founder of techARC, told CircuitDigest, “The closure of factories during the surge of the coronavirus pandemic has created huge disruptions on supply chains and also the winter storm in Texas further damaged the country’s manufacturing cluster. Now, demand suddenly soared unexpectedly as government offices, educational institutions, and corporate offices began work from home. Therefore, the chip shortages increased and the GDP also witnessed a sharp cut in percentage. The lockdown situations in the past few years has made absolutely clear that semiconductors play an important role in today’s world economy, and the costs that accompany restricted the supply.”

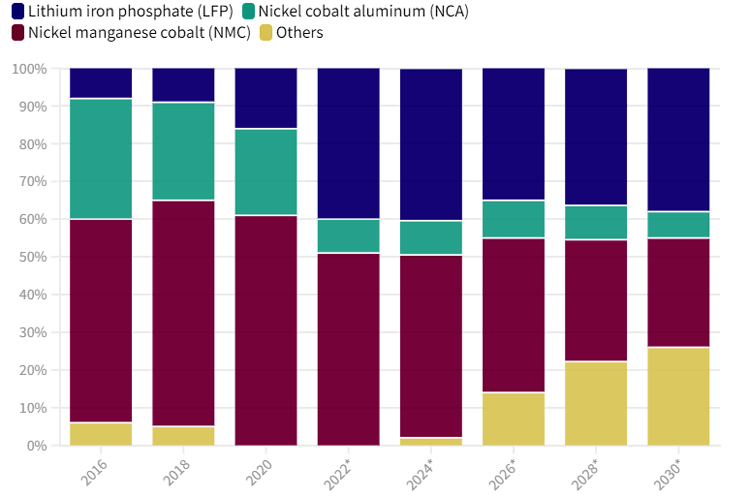

It is now clearly evident that the CHIPS and the Science Act, which was unveiled after several rounds of heated discussions, might not likely work the way it was intended. The scheme, which was unleashed with bipartisan support, was meant to boost the in-house chip manufacturing units. Even though the US is one of the leaders in advanced semiconductor design, its share of international chip production slumped 37 percent in 1990 to 12 percent currently. While speaking of the imperativeness of such technology in terms of national security, the US defense department requires 1.9 billion of them a year.

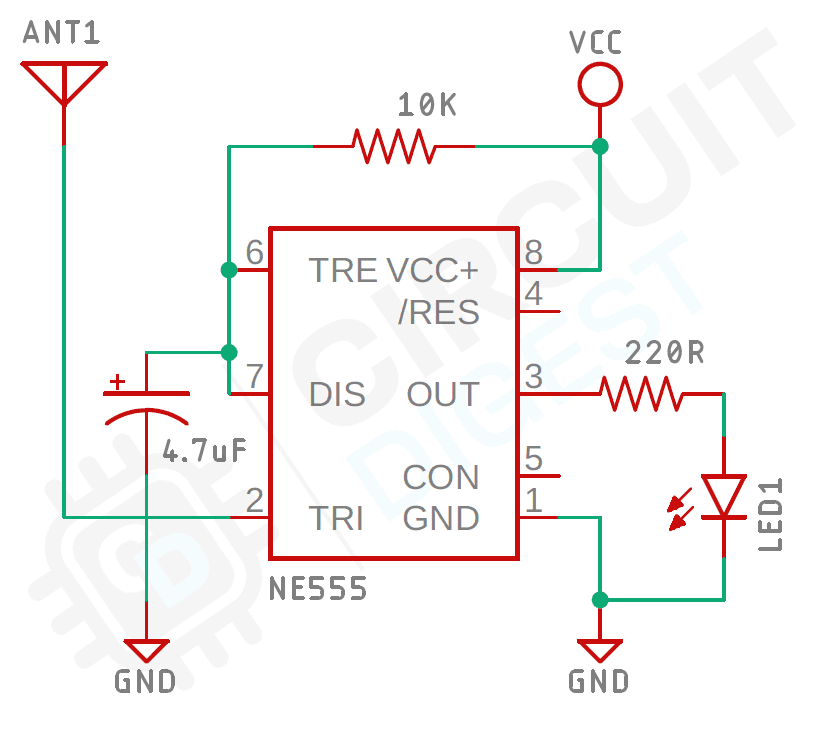

![]()

Funding For Semiconductor Manufacturing-US

The problem is now manufacturing chips in US consumer 25 percent longer duration and 50 percent more expensive than doing such in Asia. The domestic semiconductor manufacturers are now facing serious hurdles mostly due to government negligence, claim experts. According to a Bloomberg report, the red tape is a major impediment because from 1990 until 2020, the duration required to build new fabs increased by 38 percent. For instance, the Clean Air Act takes more than one and half years to give permission. Then, the review by the National Environmental Policy Act takes more than four and half years. A lot of unimportant federal laws will suddenly appear on the way and a lot of agencies must be consulted to approve the project.

Analysts told Bloomberg that such hold ups creates no confidence among private investment, increases project costs, and seriously restricts US manufacturers from competing in the international market.

Another grave hurdle is that the country does not have sufficient skilled workforce required for this sector, which researchers feel that the broken immigration system of late is responsible. A survey report highlighted that around 300,000 more skilled workforce is required to complete the ongoing fab ventures, leaving out the new ones, claims Bloomberg. Although TSMC and Intel announced their new projects in the country they are facing a lot of challenges to find proficient workforces for the same.

Most of the experts believe that these problems can be solved easily. For instance, there is a requirement to deploy fast track exemptions for semiconductor makers under the federal environment laws or better modify the law to give momentum to all such ventures and impede shallow laws. Visas must be escalated for proficient workforce, prioritize applicants with needed STEM abilities, and also increase green card allotments for foreign degree holders.

According to the market experts, various strategies can be formed and deployed in an effort to achieve chip sovereignty via the CHIPS act, but if the SMBs are not included then surely the act will fail to boost the chip economy in the country. The president has recently proclaimed who would lead the country’s export council where national security experts and CEOs of global firms were asked to spearhead, but not a single SMB company name was mentioned. According to a report by fortune.com, around 64 percent of new employment is generated by SMBs that contribute to 99.9 percent of overall trade in the US.

![]()

It is a clear fact that most of the subsidies and funding from the act will be benefited by the global companies and therefore, a sufficient percentage of the fund must be allocated to the small businesses to provide momentum in materials science, packaging, and mechanical design. The US government has called for the imperativeness of public-private partnerships, but at the same time, it is also important to have strategic alliances between MNCs and SMBs.

Now, when the CHIPS Act was finally unleashed, the government understood that the supply of nation’s chips that powers most of the electronic products from smartphones, washing machines, and cars to supercomputers, and defense products, faced a huge impediment at a difficult situation. For the manufacturing of sophisticated chips, the US is mostly relied on Taiwan. Now, geopolitical scuffles with China, the possible tussle in the South China sea as well as between North Korea and South Korea giving a blow to the semiconductor supplies and therefore, the US government was convinced about increasing the economy of the country’s chip manufacturing. But, with a couple of red tapes, and huge workforce expenses, the chip manufacturers require additional incentives to bring out the transformation.

Matthew Orf, Research Analyst with Counterpoint Technology Market Research, said "When the CHIPS act was finalized, around $200 billion worth of investments have been proclaimed to increase the chip production facilities. A couple of bigger firms like Texas Instruments, Intel, TSMC, Samsung, and Micron have announced their investments to create new foundries. Although the act has sparked private players to begin new projects, some of the shortcomings and legislations of the provisions could make it a challenging task. This is mostly because the new ventures are furnished with a lot of regulations and red tape that could cause the projects to stop for a while. Even though the funding has been allocated for job training and workforce education, the volume of the requirement of new employees, and the lack of skilled workforce will make the dream of the country of leading the semiconductor industry more difficult.”

“Most importantly, the act failed to find out the possible causes why exactly the country’s semiconductor industry weakened, mostly manufacturing. Experts believe that stern regulations and workforce costs makes manufacturing in the US more intricate than the Asian countries. Now, the problem is if the funding remains dry, how will the nation’s semiconductor industry remain globally competitive?,” added Work.

Bill Schweber is a contributing writer for Mouser Electronics and an electronics engineer who has written three textbooks on electronic communications systems, as well as hundreds of technical articles, opinion columns, and product features. In past roles, he worked as a technical website manager for multiple topic-specific sites for EE Times and as the Executive Editor and Analog Editor at EDN.

Bill Schweber is a contributing writer for Mouser Electronics and an electronics engineer who has written three textbooks on electronic communications systems, as well as hundreds of technical articles, opinion columns, and product features. In past roles, he worked as a technical website manager for multiple topic-specific sites for EE Times and as the Executive Editor and Analog Editor at EDN.