What is a Servo Motor? (Definition & Working Principle)

A servo motor is a precision motor that can rotate to specific angles with exceptional accuracy. Unlike regular motors, servo motors use a closed-loop feedback system to control position, speed, and torque precisely. If you want to rotate an object to specific angles or distances, servo motors are the ideal choice due to their servo mechanism with built-in position feedback. Popular servo motor models include SG90 (micro servo), MG995 (metal gear servo), and industrial servo motors from Siemens, Yaskawa, and Fanuc for high-precision applications.

Key Features: Servo motors are usually rated in kg/cm (kilogram per centimeter), and most hobby servos like the SG90, MG995 etc, which are often used in our electronics projects, are rated at 3kg/cm, 6kg/cm, or 12kg/cm. This rating indicates the weight the motor can lift at a specific distance. For example, a 6kg/cm servo can lift 6kg when the load is 1cm from the motor shaft.

Popular Applications: Servo motors are widely used in robotics projects, Arduino projects, RC vehicles, and home automation. This guide covers DC servo motor working principles, control methods, and practical interfacing techniques.

Table of Contents

- What is a Servo Motor? (Definition & Working Principle)

- Servo Motor Control System

- Servo Motor Working Principle

- Interfacing Servo Motors with Microcontrollers

- Servo Motor PWM Control & Programming

- Servo Motor vs Stepper Motor: Quick Comparison

- Servo Motor Types

- Servo Motor Applications

- Commonly Asked Questions about Servo Motors

- Servo Motor Specifications & Selection Guide

- Arduino Servo Motor Projects

Servo Motor Control System

The servo motor is based on a closed-loop control system with three essential components:

Control Circuit - Processes input signals and generates motor commands

Position Sensor (Potentiometer) - Provides real-time feedback on shaft position

Feedback Loop - Compares desired vs actual position to eliminate error

How it works: The control circuit of the servo motor continuously compares the input signal (desired position) with the feedback signal (actual position) obtained from the position sensor. When there's a difference, the control circuit generates an error signal that drives the motor until the desired position is reached. This closed-loop feedback system ensures precise positioning accuracy.

Servo Motor Quick Facts

- Control Signal: PWM (Pulse Width Modulation)

- Pulse Frequency: 50Hz (20ms period)

- Position Range: 0° to 180° (standard servos)

- Power Supply: 4.8V - 6V for hobby servos

- Control Pulse: 1ms = 0°, 1.5ms = 90°, 2ms = 180°

Servo Motor Working Principle

The servo motor working principle involves four key components working together: a DC/AC motor, potentiometer, gear assembly, and control circuit. Here's the step-by-step process of how servo motors work:

Step-by-Step Working Process:

Initial Position: Potentiometer generates no signal when servo is at neutral position

Input Signal: External PWM signal provides the desired position command

Error Detection: The Control circuit compares the input signal with the potentiometer feedback

Motor Movement: Error signal drives the motor in the required direction

Position Achievement: Motor stops when the potentiometer signal matches input signal

A servo consists of a Motor (DC or AC), a potentiometer, gear assembly, and a controlling circuit. First of all, we use gear assembly to reduce RPM and to increase torque of the motor. Say at initial position of servo motor shaft, the position of the potentiometer knob is such that there is no electrical signal generated at the output port of the potentiometer. Now an electrical signal is given to another input terminal of the error detector amplifier. Now the difference between these two signals, one comes from the potentiometer and another comes from other sources, will be processed in a feedback mechanism and output will be provided in terms of error signal. This error signal acts as the input for motor and motor starts rotating. Now motor shaft is connected with the potentiometer and as the motor rotates so the potentiometer and it will generate a signal. So as the potentiometer’s angular position changes, its output feedback signal changes. After sometime the position of potentiometer reaches at a position that the output of potentiometer is same as external signal provided. At this condition, there will be no output signal from the amplifier to the motor input as there is no difference between external applied signal and the signal generated at potentiometer, and in this situation motor stops rotating.

Interfacing Servo Motors with Microcontrollers

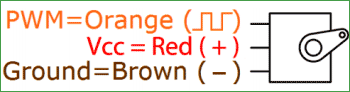

Interfacing hobby Servo motors like s90 servo motor with MCU is very easy. Servos have three wires coming out of them. Out of which two will be used for Supply (positive and negative) and one will be used for the signal that is to be sent from the MCU. An MG995 Metal Gear Servo Motor which is most commonly used for RC cars humanoid bots etc. The picture of MG995 is shown below:

The color coding of your servo motor might differ hence check for your respective datasheet.

All servo motors work directly with your +5V supply rails but we have to be careful on the amount of current the motor would consume if you are planning to use more than two servo motors a proper servo shield should be designed.

Servo Motor PWM Control & Programming

Servo motor control is achieved through PWM (Pulse Width Modulation) signals. The servo motor expects a control pulse every 20 milliseconds, and the pulse width determines the rotation angle.

PWM Control Parameters:

Pulse Period: 20ms (50Hz frequency)

1.0ms pulse width: Servo rotates to 0° position

1.5ms pulse width: Servo moves to 90° (neutral position)

2.0ms pulse width: Servo rotates to 180° position

Arduino Servo Control: If you are trying to use a servo motor with Arduino, check out the Servo.h library for easy control. This library simplifies the technicalities behind servo motor control, and you can directly set the position of the servo in degrees.

All servo motors have three wires coming out of them, as shown in the previous image above. Out of which two will be used for Supply (positive and negative), and one will be used for the signal that is to be sent from the MCU. There is a minimum pulse, a maximum pulse, and a repetition rate. Servo motor can turn 90 degree from either direction form its neutral position.

Servo motor can be rotated from 0 to 180 degrees, but it can go up to 210 degrees, depending on the manufacturer. This degree of rotation can be controlled by applying the Electrical Pulse of proper width, to its Control pin. All servo motors work directly with your +5V supply rails but we have to be careful about the amount of current the motor would consume if you are planning to use more than two servo motors a proper servo shield should be designed.

Servo Motor vs Stepper Motor: Quick Comparison

| Feature | Servo Motor | Stepper Motor |

|---|---|---|

| Control System | Closed-loop (with feedback) | Open-loop (no feedback) |

| Precision | Very High | High |

| Speed | High (constant torque) | Medium (torque decreases) |

| Cost | Higher | Lower |

| Best Applications | Robotics, CNC, high-speed tasks | 3D printers, simple positioning |

When to choose servo motors: For applications requiring high-speed precision, variable loads, smooth motion, and feedback control. When to choose stepper motors: For cost-sensitive projects, simple positioning tasks, and when open-loop control is acceptable.

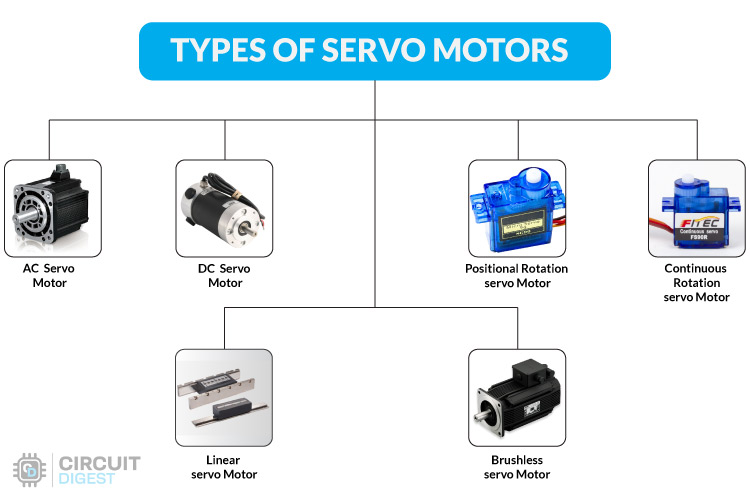

Servo Motor Types

Servo motors come in different types, each suited for specific applications. Let’s explore the main types:

1. AC Servo Motors

AC servo motors run on alternating current (AC). They are highly reliable and offer smooth performance in applications requiring precise control over high speeds and heavy loads. AC servo motors are often used in industrial machinery like conveyor belts, CNC machines, and robotics because of their durability and efficiency.

2. DC Servo Motors

DC servo motors operate on direct current (DC). They are simpler in design and easier to control than AC servo motors. Due to their quick response and affordability, they are commonly found in low-power applications such as toys, small robotics, and home automation systems.

3. Positional Rotation Servo Motors

This type is the most common and is used for controlling angular movements. They rotate to a specific angle based on input signals, making them ideal for applications like robotic arms, antenna positioning, and camera gimbals.

4. Continuous Rotation Servo Motors

Unlike positional servos, continuous rotation servos rotate freely in either direction without stopping at a fixed angle. They are perfect for creating wheels and conveyor mechanisms in robots.

5. Linear Servo Motors

Linear servo motors convert rotational motion into linear motion and are used in applications requiring straight-line movements, such as in actuators for industrial machinery and precision equipment.

6. Brushless Servo Motors

A brushless servo motor is a type of electric motor that uses permanent magnets and operates without brushes, which reduces wear and tear. It provides higher efficiency, faster speeds, and longer lifespan compared to brushed motors. They are controlled using electronic commutation, offering smooth and efficient motion.

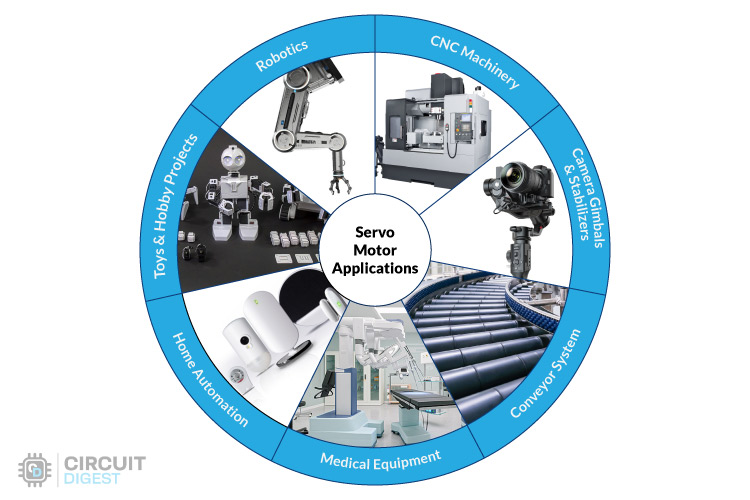

Servo Motor Applications:

Servo motors are versatile devices used to precisely control motion in various applications. Their ability to deliver accurate movements and maintain positions makes them indispensable in many industries.

Here’s a look at some common applications where servo motors play a crucial role:

1. Robotics

Servo motors are widely used in robotics for controlling movements like robotic arms, grippers, and leg joints. Their precision and responsiveness allow robots to perform tasks such as assembling parts, picking up objects, and even walking.

2. CNC Machinery

In computer numerical control (CNC) machines, servo motors drive cutting tools or machine beds with exceptional accuracy. This ensures the production of high-quality parts in industries like automotive, aerospace, and manufacturing.

3. Camera Gimbals and Stabilizers

Servo motors help stabilize cameras in gimbals, allowing smooth and steady shots, even in motion. This technology is used in drones, filmmaking, and broadcasting.

4. Conveyor Systems

Servo motors are used in conveyor belts for precise speed control and positioning in industries like packaging, food processing, and logistics. They ensure smooth material handling and sorting operations.

5. Medical Equipment

In the medical field, servo motors are used in devices like surgical robots, prosthetics, and imaging systems for precise movements and adjustments. For instance, they enable robotic arms to perform delicate surgical tasks.

6. Home Automation

Servo motors are used in automated doors, smart curtains, and remote-controlled devices. Their reliability and smooth operation enhance the functionality of modern homes.

7. Toys and Hobby Projects

Servo motors power RC cars, planes, and robots in toys and DIY projects. Their ease of use and compact size make them a favorite for hobbyists and students learning about automation and mechanics.

To learn more about the servo motor working principle and practical uses, please check below applications where controlling of the servo motor is explained with the examples:

Commonly Asked Questions about Servo Motors:

What is the difference between a servo and a stepper motor?

The main differences between servo and stepper motors are:

Control System: Servo motors use closed-loop feedback control, stepper motors use open-loop control

Precision: Servos offer higher precision due to feedback, steppers provide good accuracy in steps

Speed: Servo motors maintain torque at high speeds, stepper torque decreases with speed

Cost: Stepper motors are more cost-effective, servo motors are higher priced

Servo motors excel in robotics and high-speed applications, while stepper motors are ideal for 3D printers and simple positioning tasks.

Who are the popular Servo Motor manufacturers?

The popular servo motor manufacturers are Siemens, Mitsubishi Electric, Yaskawa Electric, Omron, Fanuc, and Panasonic. The motors from these manufacturers can be commonly found in applications such as industrial automation, robotics, and CNC machinery.

How to choose a servo motor?

Choosing the right servo motor depends the torque, speed, and precision required for your application. The most important metric in selecting the servo motors is the torque needed to move the load. Next, consider the speed requirements and ensure the motor's rated speed aligns with your needs. Feedback type is also important, if high precision is required, a motor with an encoder or other feedback systems is ideal. Additionally, factor in size, voltage, and power requirements to ensure compatibility with your system.

How to do Servo Motor Torque Calculation?

To calculate the torque of a servo motor, you need to know the force applied and the distance from the pivot point (lever arm). The basic formula for torque is:

Torque (T) = Force (F) × Distance (d)

Where:

Force (F) is the load or resistance the motor needs to move, usually measured in Newtons (N).

Distance (d) is the distance from the pivot point to the point where the force is applied, measured in meters (m).

For more accurate calculations, consider factors like motor efficiency, gear ratios, and any additional mechanical resistance in the system.

How to Control Speed of a Servo Motor?

The speed of a servo motor can be controlled by adjusting the input signal's frequency or pulse width. In a PWM (Pulse Width Modulation) control system, the motor's speed is determined by the duty cycle of the PWM signal—higher duty cycles correspond to faster speeds. To control speed:

Increase the PWM frequency: A higher frequency will increase the motor's response time.

Adjust the pulse width: The duration of the pulse affects the motor's position, and by controlling how quickly the servo reaches that position, you can influence the speed.

Using a motor driver or controller, the PWM signal can be modified to vary the motor speed as needed.

What are the latest advancements in servo motor technology?

The latest servo motor advancements in 2025 include:

Smart Servo Motors: Integration of IoT connectivity and wireless communication for remote monitoring and control

AI-Enhanced Control: Machine learning algorithms for predictive maintenance and adaptive control systems

Improved Encoders: Higher resolution absolute encoders with 20-24 bit accuracy for ultra-precise positioning

Energy Efficiency: Advanced motor designs achieving 95%+ efficiency with regenerative braking capabilities

Integrated Safety: Built-in functional safety features (SIL3/PLe) for industrial automation applications

Compact Design: Higher power density motors with integrated drives reducing installation space by 40%

Multi-Axis Control: Single controller managing up to 64 servo axes simultaneously for complex robotics

These advancements are driving adoption in collaborative robotics, autonomous vehicles, and Industry 4.0 manufacturing systems, making servo motors more intelligent, efficient, and interconnected than ever before.

Servo Motor Specifications & Selection Guide

When selecting servo motors, consider these key specifications: torque rating (measured in kg/cm), speed (rotation time), operating voltage (typically 4.8-6V), and control signal requirements (PWM frequency and pulse width range). Popular servo motor brands include Futaba, Hitec, Tower Pro (MG995, SG90), and Corona servos for hobby applications.

Arduino Servo Motor Projects

Now that you have learnt the basics of servo motor, let's take a look at some of the Arduino Servo Motor projects that we have built here at circuidigest. All these projects are available with code and Circuit Diagram for you to easily learn and build something similar on your own. If you have any questions you can leave them in the comment section or use our forums to get answers to your questions

Smart Dustbin using Arduino and Ultrasonic Sensor

Smart Dustbin as its name represents it works smartly or we can say that it is an automatic dustbin. Smart Dustbin is a very good project that we can build using the Arduino board. The project uses a sensor and a servo motor to automatically open and close the dustbin when it should be used.

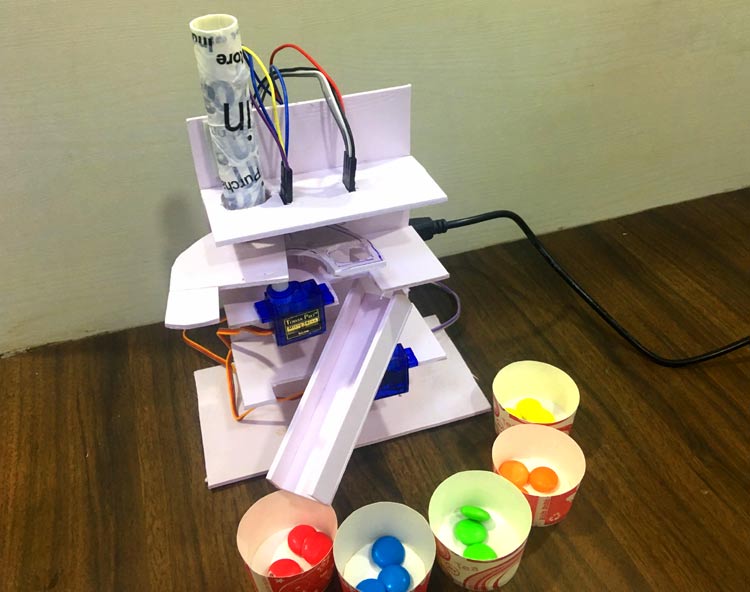

Arduino Based Color Sorter Machine

As the name suggests, color sorting is simply to sort the things according to their color. It can be easily done by seeing it but when there are too many things to be sorted and it is a repetitive task then automatic color sorting machines are very useful. This project shows how to use servo motors to sort marbles or any colored objects and place them in respectful bins.

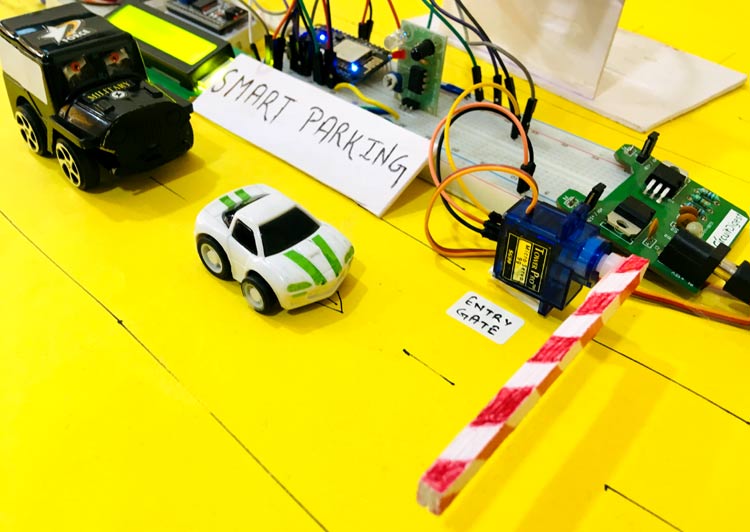

IoT based Smart Parking System

With the growing popularity of Smart Cities, there is always a demand for smart solutions for every domain. The IoT has enabled the possibility of Smart Cities with it’s over-the-internet control feature. This project shows how to use a servo motor to build an automatic tool gate that opens and closes to allow cars based on parking availability.

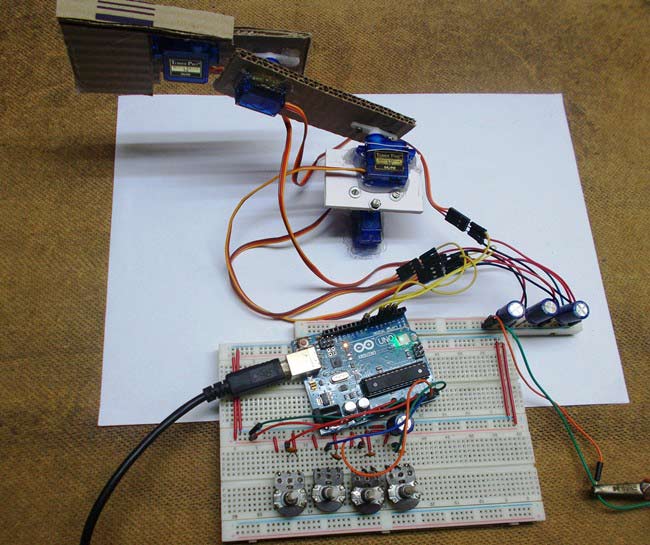

How to build a Simple Arduino Robotic Arm

In this tutorial, we are going to design an Arduino Uno based Robotic Arm from some cardboard and servo motors. The entire process of construction has been explained and it is a very fun to build project. It uses multiple servo motors to build a miniature robotic arm that can pick and place things.

Sun Tracking Solar Panel using an Arduino

The biggest crisis we are heading into is the climate change due to the excessive use of fossil fuels and to overcome these issues, we have only one solution which is utilizing Renewable Energy. This project uses a servo motor to change the direction of the solar panel based on the light availability to increase the efficiency of solar panels.

appreciation

hi,

thank you so much for your support

I'm in the industry, working with servo motors I needed to learn their

operation and controls

Request for Servo Motor PDF

Hello Sir,

I request for Servo motor PDF if you have any, I am learning about them.

Thanks

Help me to understand more about servo am in certain industry..

Thanks for your services

Electrical technology

The production of rotating magnetic field and working principal of 3-phase induction motor

It depends on the servo motor

It depends on the servo motor, if it a small torque motor then with some force you should be able to rotate it when not powered. But for metal gear high torque motors the gear ratio will be very high so it get s a bit more hard to rotate the motor.

It is a different story when the motor is powered, even a small torque motor when powered and positioned in a degree (say 90*) then we will not be able to rotate it because the motor is constantly trying to keep the motor in that position 90* so when you rotate the motor by hand it will push it back to the previous position

Also it is not recommended to rotate the motors by hand because it will damage the gears inside

servo tensioners

I need to how servo motor works for wire tensioners ?

Principal & working