The Internet of Things (IoT) has revolutionised how we control devices, enabling seamless remote monitoring and operation over a network. This tutorial presents an innovative solution for remote stepper motor control, allowing you to precisely adjust its position, monitor its performance, and receive real-time feedback directly from a simple web browser. For those new to robotics and automation, understanding the basics of a stepper motor and how it works is a great first step before diving into this advanced project. This tutorial presents an innovative solution for ESP32 stepper motor control WiFi functionality, allowing you to precisely adjust motor position, track performance, and receive real-time feedback from a simple web browser.

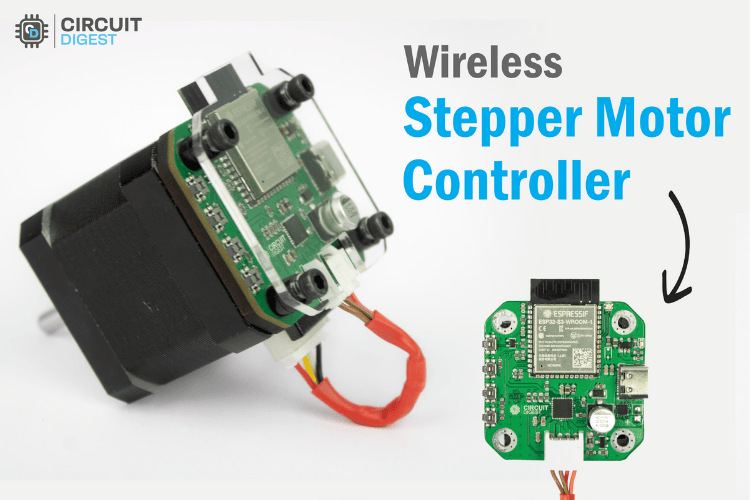

Wireless Stepper Motor Controller with ESP32 - Quick Overview

Build Time: 8-12 hours | Cost: $50-80 | Difficulty: Intermediate-Advanced

What You'll Learn: WiFi connectivity, SPI/I2C communication, USB-C Power Delivery, Microstepping control

Applications: Robotics automation, CNC machines, Home automation, Industrial prototyping

Table of Contents

In this guide, we introduce a custom-built Wireless Stepper Motor Controller with ESP32, a simple yet powerful way to add Wi-Fi stepper motor control to any project. This wireless stepper motor driver integrates robust control with modern connectivity, making it perfect for applications in automation, robotics, and industrial prototyping. With this wireless stepper driver design, you can control the motor directly through a local web interface, no extra software or complex setup required.

This project was made possible thanks to our sponsors, DigiKey. All the components used in this project were built using parts from DigiKey. You can check out our Project Files with PCB Gerber and BOM to build this wireless stepper motor controller project on your own.

Wireless Stepper Motor Controller - Explained

The Wireless Stepper Motor Controller with ESP32 is a smart motor control system that combines precision stepper motor control with wireless connectivity and intelligent power management.

Wireless Stepper Motor Control: Operate your motor remotely via a simple web interface on any browser or smartphone.

Precision and Accuracy: Achieve high-precision positioning with up to 1/256 microstepping and real-time encoder feedback from the AS5600 sensor.

Smart Power Management: Automatically negotiate optimal power levels from USB-C Power Delivery (PD) sources, from 5V to 20V.

Real-time Monitoring: Monitor critical data, including motor temperature, current draw, and exact position, all updated live on the web dashboard.

Intuitive Visual Feedback: Use colour-coded RGB LED indicators to instantly see the system's power status and motor activity.

Key Features of our Wireless Stepper Driver

- Web-Based Control: Simple HTTP commands control all motor functions - no special software needed

- Precision Movement: up to 1/256 microstepping with closed-loop positioning using AS5600 magnetic encoder

- Smart Power Management: Automatically selects 5V, 9V, 12V, or 15V from USB-PD sources

- Visual Feedback: RGB LEDs show power level (colour-coded) and motor activity (blinking patterns)

- Real-Time Monitoring: Live status updates including temperature, current draw, and position

- Non-Blocking Operation: The Web server stays responsive while the motor runs smoothly

Components Required for the Wireless Stepper Motor Controller Project

Wireless Stepper Motor Controller with ESP32 Wiring Diagram

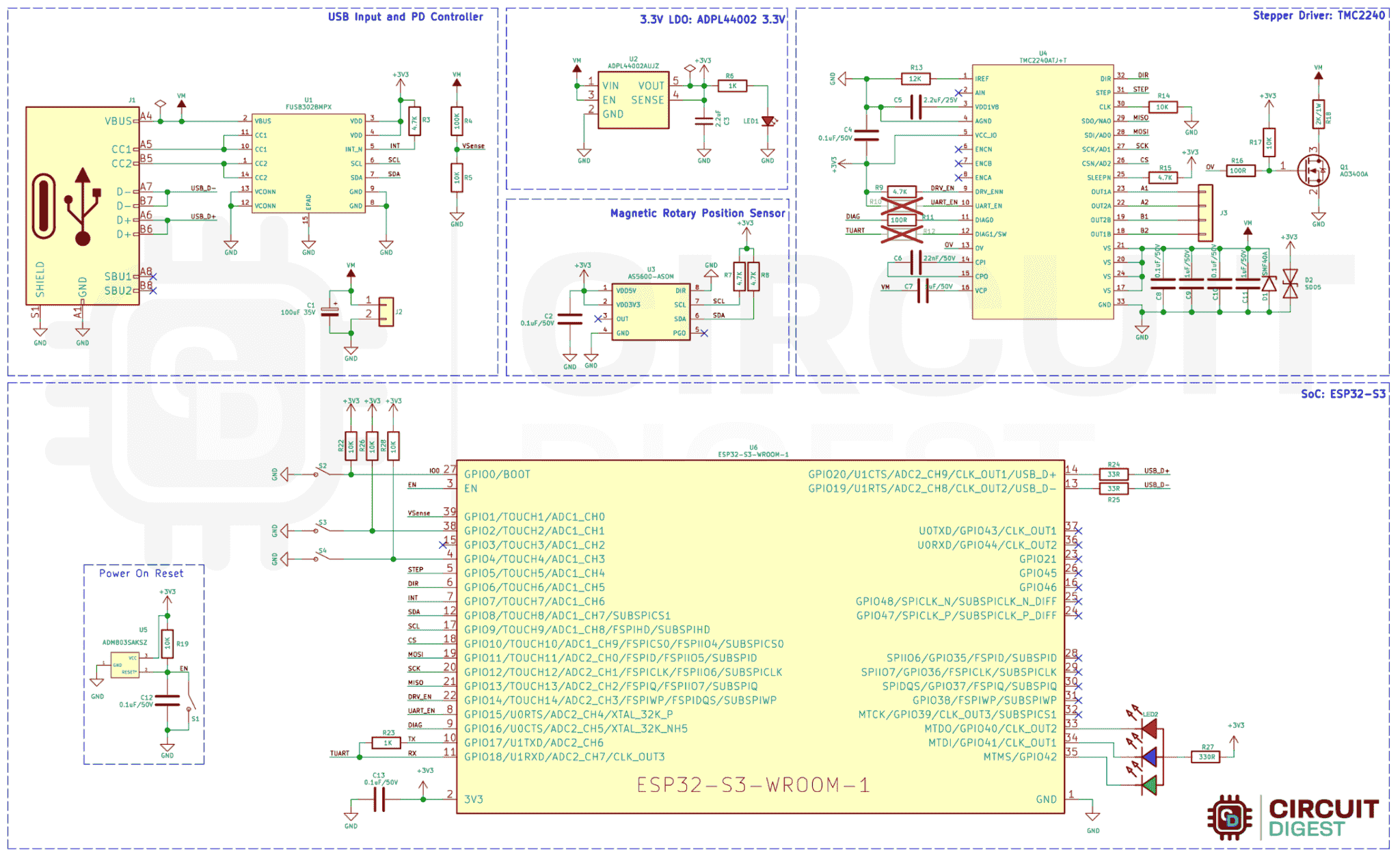

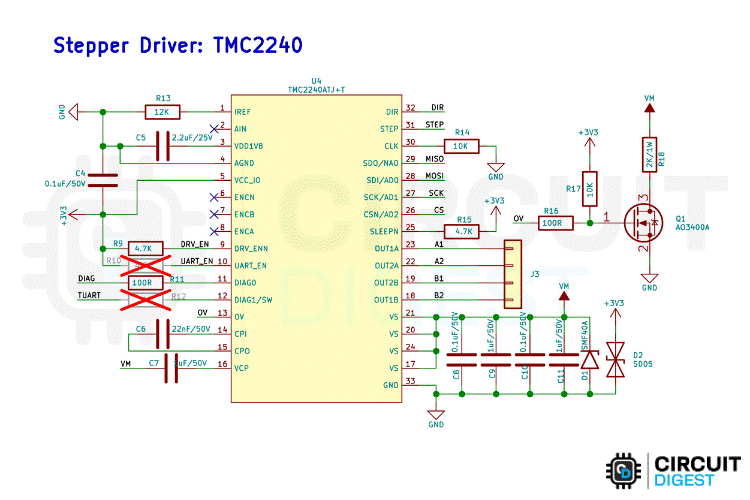

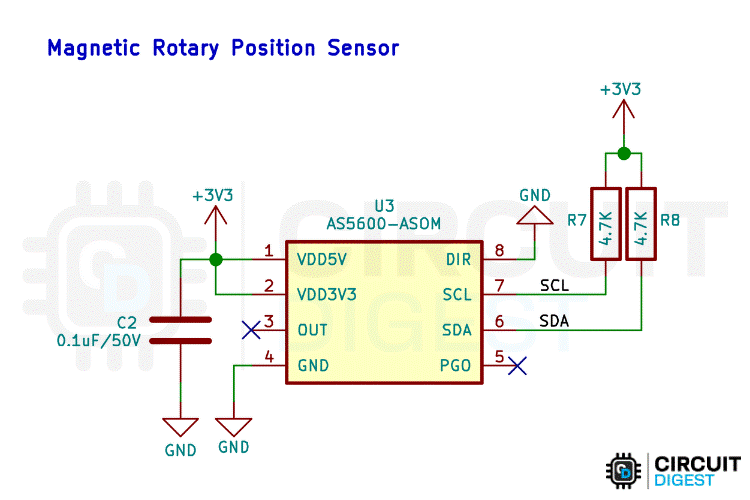

The complete circuit diagram for the Wireless Stepper Motor Driver is shown below. This comprehensive wireless stepper motor controller with ESP32 wiring diagram demonstrates how to control a stepper motor with ESP32 effectively. It can also be downloaded in PDF format from the GitHub repo linked at the end.

The schematic is fully customizable. You can tweak any part of the design to suit your specific needs.

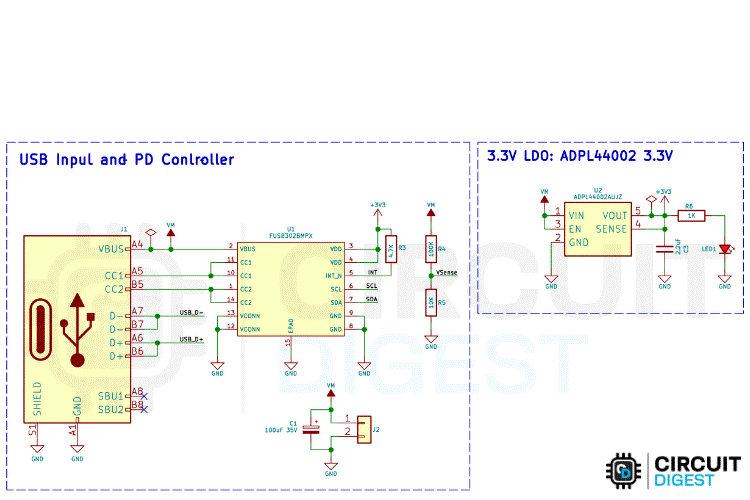

First, the power section, which combines a USB Power Delivery (PD) controller and a Low Dropout (LDO) regulator to manage voltage input and provide a stable 3.3V output. The USB PD controller used is the FUSB302BMPX, which negotiates power profiles through the USB-C connector. It connects to the CC1 and CC2 lines via 5.1kΩ pull-down resistors to detect cable orientation and voltage profiles. Once a power contract is negotiated, the VBUS line delivers the required voltage (e.g., 9V or 12V), which is then passed to the LDO regulator.

The LDO used is the ADP4140002, which steps down the negotiated voltage to a clean 3.3V. This 3.3V is used to power the ESP32-S3 microcontroller, the stepper motor driver’s logic section, the magnetic position sensor, and the indicator LEDs.

The LDO includes input and output capacitors for voltage stability and noise filtering, while the PD controller communicates with the ESP32-S3 via I²C and notifies it of any power events using an interrupt pin.

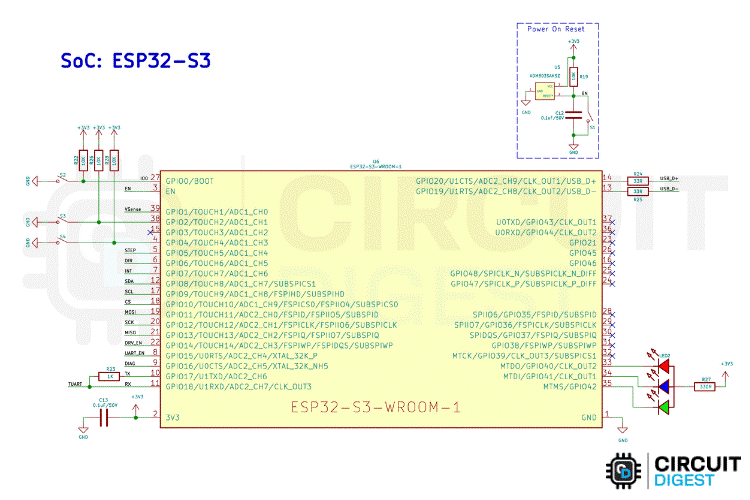

The core of the system is the ESP32-S3-WROOM-1 module, which provides Wi-Fi and Bluetooth connectivity along with multiple GPIOs for control and communication. This setup demonstrates exactly how to control a stepper motor with ESP32 efficiently. Its GPIO0 and EN pins are connected to push buttons for boot mode and reset functionality. It communicates via USB using its native D+ and D– pins, which are routed through 33Ω resistors. Previously, we have built many projects using ESP32 board; you can also check them out if interested.

The I²C bus on GPIO9 (SCL) and GPIO8 (SDA) connects to the USB PD controller and the magnetic position sensor, allowing two-way communication for power and position monitoring. The ESP32 also interfaces with the TMC2240 stepper driver through both SPI and dedicated control pins. It uses GPIO10–13 for SPI communication and GPIO5 and GPIO6 for STEP and DIR signals.

In addition, three LEDs are connected to GPIO40, GPIO41, and GPIO42 via 330Ω resistors, which serve as status indicators.

The TMC2240 stepper motor driver handles the precise control of a stepper motor. It receives its motor power input (VM) from an external power source and logic power from the 3.3V LDO. The motor is controlled using STEP and DIR signals from the ESP32, while the SPI bus is used to configure internal settings and read diagnostics. The driver also includes enable and diagnostic pins for fine control and feedback. Protection is implemented using a TVS diode across the VM line to handle voltage spikes and sense resistors for monitoring motor current. The driver’s output pins are connected directly to the motor coils, enabling smooth microstepping operation. For those using A4988 drivers, our A4988 Arduino interface tutorial will guide you step by step.

A magnetic rotary position sensor, based on the AS5600, is included for detecting the angular position of a rotating shaft. This sensor communicates over I²C, sharing the same bus as the PD controller. It is powered by the 3.3V rail and includes a decoupling capacitor for noise filtering. The sensor provides precise angle data to the ESP32, enabling closed-loop motor control or position tracking applications.

With this, the Schematic part gets covered. Next comes the PCB Part.

By integrating a versatile ESP32 microcontroller with the high-performance TMC2240 driver and an AS5600 encoder, this ESP32 stepper motor control wifi system provides unmatched precision and real-time feedback.

Custom PCB Design for Wireless Stepper Driver

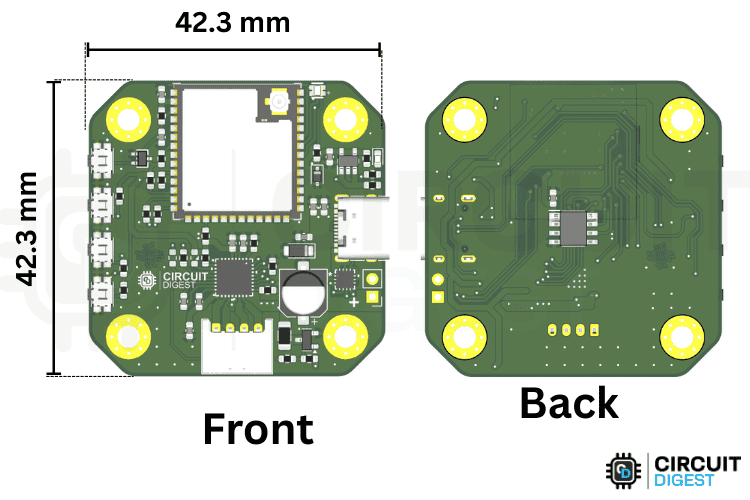

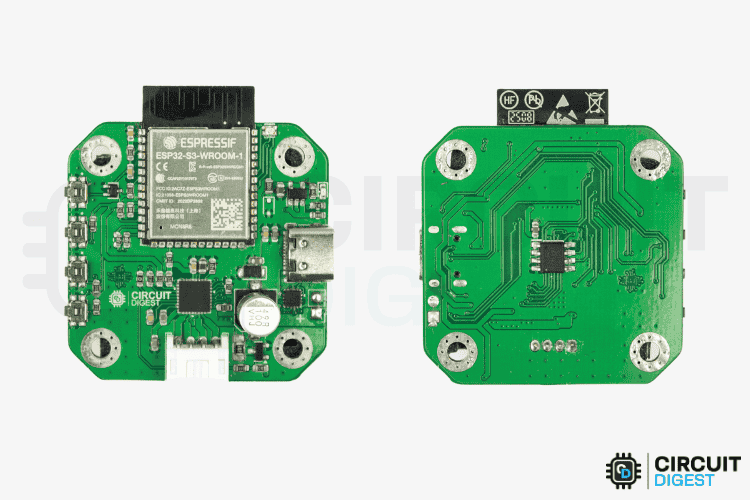

For this project, we decided to create a custom PCB. This ensures that the final product is as compact as possible and easy to assemble and use. The PCB was designed using KiCad, and all the design files are available for download from the GitHub repository linked below this article.

The PCB dimensions are approximately 42.3 mm x 42.3 mm, which is exactly the general size of stepper motors like the NEMA 17. So, it easily mounts behind the motor.

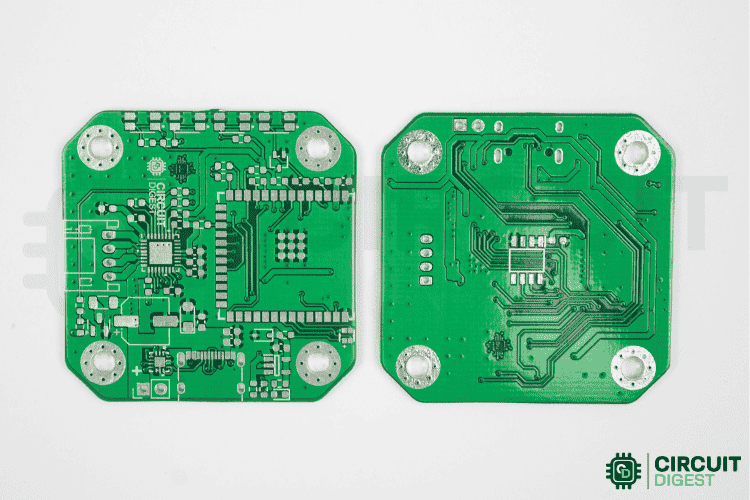

Once the PCB design was complete and fully verified, we sent the respective Gerber files to a PCB fabrication service for manufacturing. Below, you can see the raw fabricated PCB.

Assembling Guide: Building the Stepper Motor Controller

The first step in assembling the PCB was to sort all the required components as listed in the BOM (Bill of Materials). After sorting, we placed the components on the PCB and soldered them one by one.

To simplify this process, you can use an SMD stencil to apply solder paste and then place the components before reflowing the PCB using either an SMD rework station or a reflow oven. However, you are not limited to these methods; manual soldering works just as well for small batches.

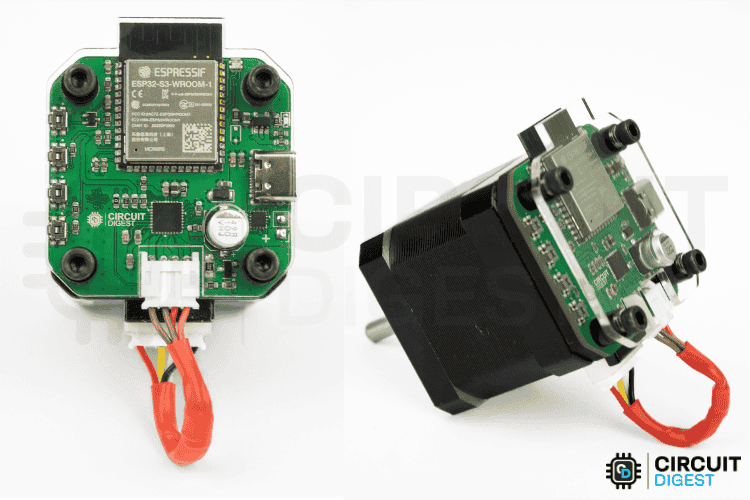

Above is the image of a fully assembled Wireless Stepper Motor Controller PCB.

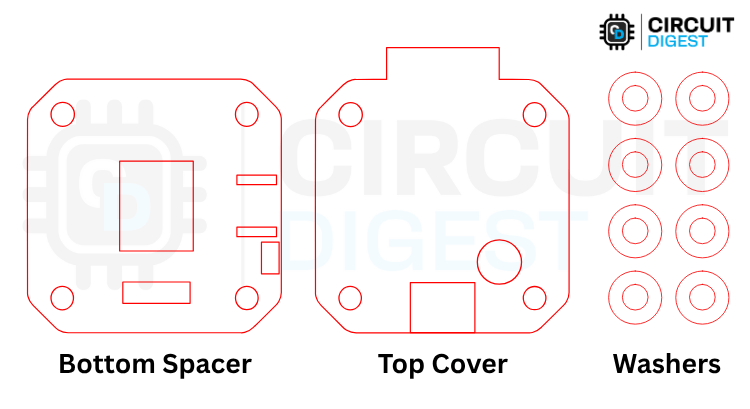

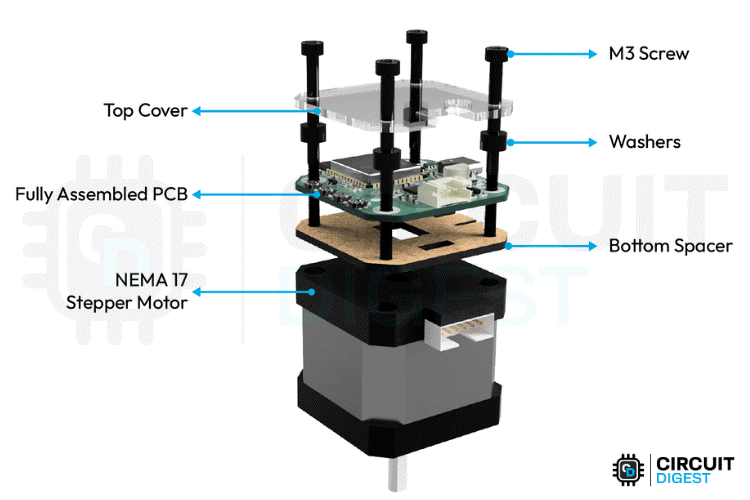

Laser Cut Enclosure for Stepper Driver

To make the enclosure simple and quick, we chose laser cutting. There are two primary parts we need, along with some washers. At the bottom, we actually need a spacer to compensate for the magnetic encoder IC’s height. On the top, we need to cover the PCB to avoid external damage.

Above, you can see the image of the cutouts.

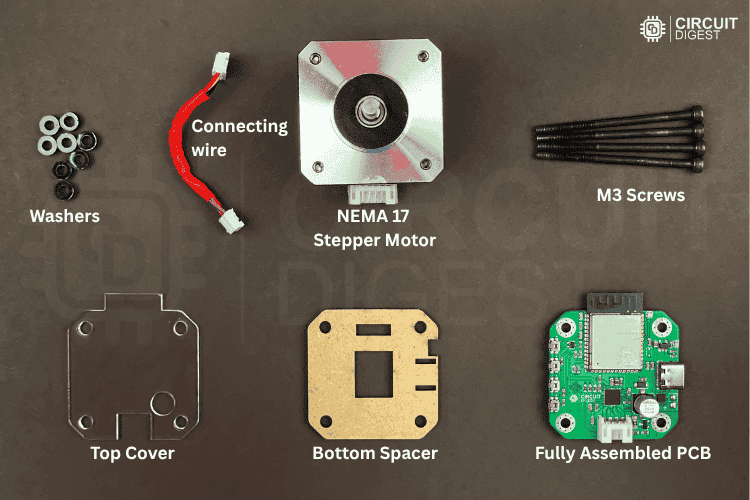

Below, you can see the components required for assembling the Wireless Stepper Motor Driver.

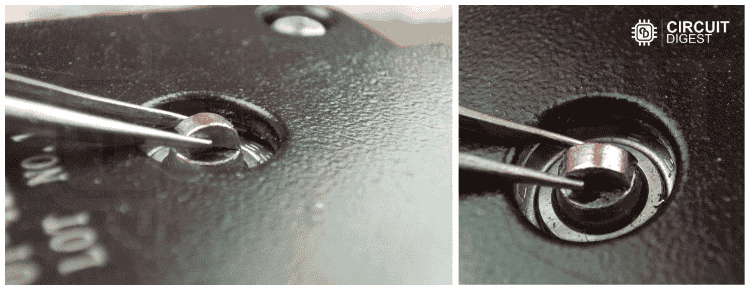

The assembly is very simple. The only part that requires extra attention is the placement of the magnet on the shaft. This is important, as it is responsible for sensing the shaft's position.

I broke a normal 3mm diameter magnet in half and placed one half as shown in the image below. I used Feviquick to stick the magnet.

Next comes the enclosure. It is assembled as shown in the following image.

After full assembly, the final project looks like the image below. You can see the compactness of this project.

The reason for not including any side enclosures is to provide ventilation for the driver IC, making it a perfect companion for fast prototyping.

This DIY wireless stepper motor controller project offers a powerful and compact solution for robotics projects and home automation projects. By integrating a versatile ESP32 microcontroller with the high-performance TMC2240 driver and an AS5600 encoder, this system provides unmatched precision and real-time feedback. Its web-based control and smart power management make it an ideal tool for rapid prototyping, robotics, and industrial applications. You can download all the code and design files from the GitHub repository linked below to build your own.

Technical Summary and GitHub Repository

A quick technical summary that outlines the main idea, principle of operations, and main properties of the project. In addition, the GitHub Repository includes the source code, design files, and documentation for ease of use. This summary provides the reader with a quick overview of the project and a sufficient method to replicate it with open-source materials.

Programming the ESP32: Arduino Code Overview

The core of this wireless stepper motor controller project is its versatile Arduino code, which seamlessly integrates several advanced technologies. The firmware demonstrates exactly how to control a stepper motor with ESP32 and is designed to combine:

TMC2240 Stepper Driver: For ultra-quiet and precise stepper motor control.

USB-C Power Delivery: To enable intelligent, variable power sourcing.

AS5600 Magnetic Encoder: For high-resolution, closed-loop position feedback.

RGB Status LEDs: To provide a clear visual indication of system states.

Web Server Interface: For convenient remote control and real-time monitoring.

The system allows you to control a stepper motor through a web browser while monitoring power, temperature, and position in real-time.

Libraries and Dependencies

This code uses several libraries to handle different components.

#include <SPI.h>

#include <WiFi.h>

#include <WebServer.h>

#include "AS5600.h"

#include <Wire.h>

#include <PD_UFP.h>

#include <ArduinoJson.h>

#include "index_page.h"- "SPI.h" – Communicates with the TMC2240 driver using Serial Peripheral Interface (Built-in library)

- "Wire.h" – Handles I2C communication with the magnetic encoder (Built-in library)

- "WiFi.h" and "WebServer.h" – Enable WiFi connectivity and web-based control (Built-in libraries)

- "AS5600.h" – Controls the magnetic encoder for position sensing

- "PD_UFP.h" – Manages USB-C Power Delivery negotiation

- "ArduinoJson.h" – Formats data for web API responses

- "index_page.h" – Contains the HTML/CSS/JavaScript for the web interface (Custom library)

Pin Definitions and Hardware Connections

The system uses specific microcontroller pins for different components to ensure proper communication and control.

const int MOSI_PIN = 11, MISO_PIN = 13, SCK_PIN = 12, CS_PIN = 10;

const int EN_PIN = 14;

const int STEP_PIN = 5;

const int DIR_PIN = 6; The TMC2240 stepper driver uses an SPI interface with MOSI on pin 11, MISO on pin 13, SCK on pin 12, and CS on pin 10, while motor control pins include Enable on pin 14, Step on pin 5, and Direction on pin 6.

Wire.setPins(8, 9);

The AS5600 magnetic encoder communicates via I2C using pins 8 for SDA and 9 for SCL.

const int RGB_RED_PIN = 40;

const int RGB_GREEN_PIN = 42;

const int RGB_BLUE_PIN = 41;The RGB LED uses three separate pins for colour control with Red on pin 40, Green on pin 42, and Blue on pin 41.

#define FUSB302_INT_PIN 7The USB-C Power Delivery system uses pin 7 as an interrupt pin for the FUSB302 controller.

Global Variables and Configuration

The system maintains various global variables to track different aspects of operation.

bool isMotorEnabled = false;

bool currentDirection = true;

bool isMovingToAngle = false;

bool pd_negotiation_complete = false;

int currentSpeed = DEFAULT_SPEED;

uint16_t motorCurrent = DEFAULT_CURRENT;

uint8_t microSteps = DEFAULT_MICROSTEPS;

int STEPS_PER_REVOLUTION = STEPS_PER_REV * DEFAULT_MICROSTEPS;Motor control variables include isMotorEnabled to track whether the motor is powered on, currentDirection to store the rotation direction, and isMovingToAngle to indicate when automatic angle positioning is active. Motor parameters such as currentSpeed, motorCurrent, and microSteps can be adjusted during operation to fine-tune performance.

float targetAngle = 0.0;

float currentAngleTolerance = 0.0;

float cachedCurrentAngle = 0.0;

float cachedTemperature = 0.0;

int cachedCurrentB = 0; Position control variables like targetAngle and currentAngleTolerance handle precise angle-based movements, while the system caches sensor readings in variables like cachedCurrentAngle and cachedTemperature to reduce communication overhead and improve performance.

struct PDProfile {

float voltage;

float current;

const char* name;

};

const PDProfile pd_profiles[] = {

{5.0, 3.0, "5V/3A"},

{9.0, 2.0, "9V/2A"},

{9.0, 3.0, "9V/3A"},

{12.0, 1.5, "12V/1.5A"},

{15.0, 2.0, "15V/2A"},

{20.0, 1.5, "20V/1.5A"}

};The power delivery configuration uses a pd_profiles array that defines different voltage and current combinations, including 5V, 9V, 12V, 15V, and 20V options that can be negotiated with USB-C power sources.

const RGBColor COLOR_OFF = { 0, 0, 0 };

const RGBColor COLOR_RED = { 255, 0, 0 };

const RGBColor COLOR_GREEN = { 0, 255, 0 };

const RGBColor COLOR_BLUE = { 0, 0, 255 };

const RGBColor COLOR_YELLOW = { 255, 255, 0 };

const RGBColor COLOR_PURPLE = { 255, 0, 255 };

const RGBColor COLOR_CYAN = { 0, 255, 255 };

const RGBColor COLOR_WHITE = { 255, 255, 255 };

const RGBColor COLOR_ORANGE = { 255, 165, 0 };

const RGBColor COLOR_PINK = { 255, 20, 147 }; LED status management relies on RGB colour constants and timing variables to control the visual feedback system, with different colours indicating various states such as WiFi connectivity, power levels, and motor operation status.

Setup Function - System Initialisation

The setup function initialises all system components in a carefully planned sequence to ensure proper operation for the ESP32 stepper motor control Wi-Fi functionality.

Serial.begin(115200);

Serial.println("TMC2240 Stepper Motor Control");

initRGBLED();

Wire.setPins(8, 9);

Wire.begin();

PD_UFP.init(FUSB302_INT_PIN, PD_POWER_OPTION_MAX_5V);

PD_UFP.set_power_option(PD_POWER_OPTION_MAX_5V);

as5600.begin(4);

as5600.setDirection(AS5600_CLOCK_WISE);

if (!as5600.isConnected()) {

Serial.println("Warning: AS5600 encoder not connected!");

}

pinMode(EN_PIN, OUTPUT);

pinMode(STEP_PIN, OUTPUT);

pinMode(DIR_PIN, OUTPUT);

pinMode(CS_PIN, OUTPUT);

pinMode(MOSI_PIN, OUTPUT);

pinMode(MISO_PIN, INPUT);

pinMode(SCK_PIN, OUTPUT);

pinMode(UART_EN_PIN, OUTPUT);

digitalWrite(CS_PIN, HIGH);

digitalWrite(EN_PIN, HIGH); digitalWrite(UART_EN_PIN, LOW);

digitalWrite(DIR_PIN, currentDirection);

SPI.begin(SCK_PIN, MISO_PIN, MOSI_PIN, CS_PIN);The process begins with serial communication initialisation for debugging purposes, followed by RGB LED testing with a colour sequence of red, green, and blue to verify functionality. Hardware component setup includes configuring I2C communication for the magnetic encoder, initialising the Power Delivery controller with 5V as the starting profile, and setting up all GPIO pins for motor control and SPI communication.

// Connect to WiFi network

WiFi.begin(ssid, password);

Serial.print("Connecting to WiFi");

setRGBColor(COLOR_YELLOW); // Yellow while connecting

// Wait for WiFi connection

while (WiFi.status() != WL_CONNECTED) {

delay(500);

Serial.print(".");

}

Serial.println("\nConnected to WiFi");

Serial.print("IP Address: ");

Serial.println(WiFi.localIP());

setRGBColor(COLOR_GREEN); // Green when connected

delay(1000);

// Main page route - serves the web interface

server.on("/", HTTP_GET, []() {

lastClientRequest = millis();

webClientConnected = true;

server.send(200, "text/html", html_page);

});

// Motor enable route - enables the stepper motor

server.on("/enable", HTTP_GET, []() {

lastClientRequest = millis();

webClientConnected = true;

digitalWrite(EN_PIN, LOW);

isMotorEnabled = true;

updateMotorStatusColor();

server.send(200, "text/plain", "Motor Enabled");

});

// Motor disable route - disables the stepper motor

server.on("/disable", HTTP_GET, []() {

lastClientRequest = millis();

webClientConnected = true;

digitalWrite(EN_PIN, HIGH);

isMotorEnabled = false;

updateMotorStatusColor();

server.send(200, "text/plain", "Motor Disabled");

});

// Emergency stop route - immediately stops all motor activity

server.on("/stop", HTTP_GET, []() {

lastClientRequest = millis();

webClientConnected = true;

digitalWrite(EN_PIN, HIGH);

digitalWrite(STEP_PIN, LOW);

isMotorEnabled = false;

isMovingToAngle = false;

currentSpeed = DEFAULT_SPEED;

updateMotorStatusColor();

String response = "{\"status\":\"Emergency Stop Activated\",\"motorEnabled\":false}";

server.send(200, "application/json", response);

Serial.println("EMERGENCY STOP ACTIVATED");

});

// Speed control route - sets motor speed

server.on("/speed", HTTP_GET, []() {

lastClientRequest = millis();

webClientConnected = true;

if (server.hasArg("value")) {

currentSpeed = server.arg("value").toInt();

server.send(200, "text/plain", "Speed set to " + String(currentSpeed));

}

});

// Manual movement route - moves motor by specified steps

server.on("/move", HTTP_GET, []() {

lastClientRequest = millis();

webClientConnected = true;

if (server.hasArg("steps")) {

int targetSteps = server.arg("steps").toInt();

moveMotor(currentDirection, targetSteps);

server.send(200, "text/plain", "Moving " + String(targetSteps) + " steps");

}

});

// System status route - returns current system status

server.on("/status", HTTP_GET, []() {

lastClientRequest = millis();

webClientConnected = true;

bool pd_ready = PD_UFP.is_power_ready();

float pd_voltage = (pd_ready && pd_negotiation_complete) ? PD_UFP.get_voltage() : 0.0;

float pd_current = (pd_ready && pd_negotiation_complete) ? PD_UFP.get_current() : 0.0;

String status = "{\"temperature\":" + String(cachedTemperature, 1) +

",\"current\":" + String(cachedCurrentB) +

",\"pd_ready\":" + String(pd_ready ? "true" : "false") +

",\"pd_negotiated\":" + String(pd_negotiation_complete ? "true" : "false") +

",\"pd_voltage\":" + String(pd_voltage, 2) +

",\"pd_current\":" + String(pd_current, 2) + "}";

server.send(200, "application/json", status);

});

// Motor current control route - sets motor current

server.on("/current", HTTP_GET, []() {

lastClientRequest = millis();

webClientConnected = true;

if (server.hasArg("value")) {

motorCurrent = server.arg("value").toInt();

setCurrent(motorCurrent);

server.send(200, "text/plain", "Motor current set to " + String(motorCurrent) + " mA");

}

});

// Microstepping control route - sets microstepping resolution

server.on("/microsteps", HTTP_GET, []() {

lastClientRequest = millis();

webClientConnected = true;

if (server.hasArg("value")) {

microSteps = server.arg("value").toInt();

setMicrostepping(microSteps);

server.send(200, "text/plain", "Microstepping set to 1/" + String(microSteps));

}

});

// Encoder status route - returns current encoder readings

server.on("/encoder", HTTP_GET, []() {

lastClientRequest = millis();

webClientConnected = true;

String json = String("{\"speed\":0") +

",\"rawAngle\":" + String(cachedCurrentAngle, 1) +

",\"current\":" + String(cachedCurrentB) + "}";

server.send(200, "application/json", json);

});

// Power status route - returns PD power status

server.on("/power_status", HTTP_GET, []() {

lastClientRequest = millis();

webClientConnected = true;

StaticJsonDocument<200> doc;

bool power_ready = PD_UFP.is_power_ready();

float voltage = 0.0;

float current = 0.0;

if (power_ready && pd_negotiation_complete) {

voltage = PD_UFP.get_voltage();

current = PD_UFP.get_current();

}

bool pd_connected = power_ready && pd_negotiation_complete && voltage > 0.0 && current > 0.0;

doc["pd_connected"] = pd_connected;

doc["pd_negotiated"] = pd_negotiation_complete;

if (pd_connected) {

doc["voltage"] = voltage;

doc["current"] = current;

doc["power"] = voltage * current;

}

String response;

serializeJson(doc, response);

server.send(200, "application/json", response);

});

server.on("/direction", HTTP_GET, []() {

lastClientRequest = millis();

webClientConnected = true;

if (server.hasArg("dir")) {

currentDirection = (server.arg("dir") == "true");

digitalWrite(DIR_PIN, currentDirection);

server.send(200, "text/plain", "Direction set to " + String(currentDirection ? "Forward" : "Backward"));

} else {

server.send(400, "text/plain", "Missing direction parameter");

}

});

server.on("/set_angle", HTTP_GET, []() {

lastClientRequest = millis();

webClientConnected = true;

if (server.hasArg("angle")) {

targetAngle = server.arg("angle").toFloat();

currentAngleTolerance = calculateAngleTolerance(microSteps);

isMovingToAngle = true;

server.send(200, "text/plain", "Moving to angle " + String(targetAngle) + "° with accuracy ±" + String(currentAngleTolerance) + "°");

} else {

server.send(400, "text/plain", "Missing angle parameter");

}

});

// Web server endpoint to set Power Delivery (PD) profile

server.on("/setPD", HTTP_GET, []() {

lastClientRequest = millis();

webClientConnected = true;

if (server.hasArg("profile")) {

int profile = server.arg("profile").toInt();

PD_power_option_t power_option;

switch (profile) {

case 5:

power_option = PD_POWER_OPTION_MAX_5V;

currentPDProfile = 0;

break;

case 9:

power_option = PD_POWER_OPTION_MAX_9V;

currentPDProfile = 1;

break;

case 12:

power_option = PD_POWER_OPTION_MAX_12V;

currentPDProfile = 2;

break;

case 15:

power_option = PD_POWER_OPTION_MAX_15V;

currentPDProfile = 3;

break;

case 20:

power_option = PD_POWER_OPTION_MAX_20V;

currentPDProfile = 4;

break;

default:

server.send(400, "text/plain", "Invalid profile");

return;

}

PD_UFP.set_power_option(power_option);

for (int i = 0; i < 5; i++) {

PD_UFP.run();

delay(100);

}

forceUpdatePDColors();

server.send(200, "text/plain", "PD profile set to " + String(profile) + "V");

} else {

server.send(400, "text/plain", "Missing profile parameter");

}

});

// Start the web server

server.begin();

Serial.println("HTTP server started");

// Configure the TMC2240 stepper motor driver

configureDriver();

WiFi connection establishment is a crucial step where the system connects to the specified network, displaying a yellow LED during the connection process and switching to green when successful. The system then displays the assigned IP address for web access. Web server route configuration creates multiple HTTP endpoints, including the root path for serving the main control interface, enable and disable routes for motor power control, parameter adjustment routes for speed, current, and microstepping settings, movement command routes for basic stepping and angle positioning, real-time data routes for status and encoder information, and power delivery management routes. Finally, the TMC2240 driver is configured with default settings, including current limits, microstepping resolution, and chopper timing parameters. To ensure the best performance for your specific motor, you can use our dedicated stepper motor calculator tool

Main Loop - Continuous Operation

The main loop continuously handles multiple tasks to maintain system operation and responsiveness.

server.handleClient();

PD_UFP.run();

updateLEDBlink();

static unsigned long lastStatusLEDUpdate = 0;

if (millis() - lastStatusLEDUpdate >= 100) {

updateStatusLED();

lastStatusLEDUpdate = millis();

}

if (millis() - last_pd_check >= PD_CHECK_INTERVAL) {

bool was_negotiated = pd_negotiation_complete;

if (PD_UFP.is_power_ready()) {

if (!pd_negotiation_complete) {

Serial.println("PD Power Negotiation Complete!");

pd_negotiation_complete = true;

lastPDVoltageCheck = 0;

}

} else {

if (pd_negotiation_complete) {

Serial.println("PD Power Negotiation Lost!");

pd_negotiation_complete = false;

pdColorModeActive = false; }

}

last_pd_check = millis();

}Request processing involves the server.handleClient() to handle incoming web requests and PD_UFP.run() to maintain power delivery negotiation with USB-C sources. Visual feedback management updates the LED system based on priority levels, where WiFi connection issues display red blinking, successful PD negotiation shows voltage-coded colours, and normal operation indicates connection status.

if (millis() - lastEncoderUpdate >= ENCODER_UPDATE_INTERVAL) {

updateCachedValues(); lastEncoderUpdate = millis();

}

if (isMovingToAngle) {

moveToAngle(); }

if (millis() - lastStatusUpdate >= STATUS_UPDATE_INTERVAL) {

Serial.println("System Status: Motor " + String(isMotorEnabled ? "Enabled" : "Disabled") +

", Temp: " + String(cachedTemperature, 1) + "°C" +

", WiFi: " + String(WiFi.status() == WL_CONNECTED ? "Connected" : "Disconnected") +

", Web Client: " + String(webClientConnected ? "Active" : "Inactive") +

", PD Mode: " + String(pdColorModeActive ? "Active" : "Inactive"));

lastStatusUpdate = millis();

}Sensor updates occur periodically to read the magnetic encoder and TMC2240 temperature sensor, with values cached to avoid excessive communication that could slow down the system. Automatic movement functionality activates when isMovingToAngle is true, causing the moveToAngle() function to continuously adjust motor position toward the target angle. Status reporting provides periodic serial output with system information, including motor state, temperature readings, and connection status for debugging and monitoring purposes.

Key Functions Explained

void setRGBColor(RGBColor color) {

analogWrite(RGB_RED_PIN, color.red); // Set red component

analogWrite(RGB_GREEN_PIN, color.green); // Set green component

analogWrite(RGB_BLUE_PIN, color.blue); // Set blue component

currentLEDColor = color; // Update current color

}

void updateStatusLED() {

// Highest Priority: WiFi disconnected - Red fast blink

if (WiFi.status() != WL_CONNECTED) {

pdColorModeActive = false;

enableLEDBlink(COLOR_RED, 200); // Red fast blink for WiFi issues

return;

}

// Second Priority: PD is ready and negotiated - show voltage colors

if (PD_UFP.is_power_ready() && pd_negotiation_complete) {

// Only update PD colors periodically to avoid constant changes

if (millis() - lastPDVoltageCheck >= PD_CHECK_INTERVAL) {

updatePDVoltageColor();

lastPDVoltageCheck = millis();

}

return; // Exit here - PD colors are active

}

// Third Priority: WiFi connected but no PD - show connection status

pdColorModeActive = false;

// Update client connection status based on timeout

if (millis() - lastClientRequest > CLIENT_TIMEOUT) {

webClientConnected = false;

}

if (webClientConnected) {

// WiFi connected and web client active - Solid Green

setRGBColor(COLOR_GREEN);

ledBlinkEnabled = false;

} else {

// WiFi connected but no web client - Blue slow blink

enableLEDBlink(COLOR_BLUE, 1000);

}

}RGB LED control functions such as setRGBColor() and updateStatusLED() manage the visual feedback system that provides immediate status information to users. The system uses a colour-coding scheme where green indicates 5V power, blue represents 9V, purple shows 12V, orange displays 15V, and pink indicates 20V power levels.

// Write data to TMC2240 register via SPI

void writeRegister(uint8_t address, uint32_t value) {

digitalWrite(CS_PIN, LOW); // Select TMC2240

SPI.transfer(address | 0x80); // Send address with write bit

SPI.transfer((value >> 24) & 0xFF); // Send MSB

SPI.transfer((value >> 16) & 0xFF); // Send byte 2

SPI.transfer((value >> 8) & 0xFF); // Send byte 1

SPI.transfer(value & 0xFF); // Send LSB

digitalWrite(CS_PIN, HIGH); // Deselect TMC2240

}

// Read data from TMC2240 register via SPI

uint32_t readRegister(uint8_t address) {

digitalWrite(CS_PIN, LOW); // Select TMC2240

SPI.transfer(address & 0x7F); // Send address with read bit

uint32_t value = 0;

value |= (uint32_t)SPI.transfer(0) << 24; // Read MSB

value |= (uint32_t)SPI.transfer(0) << 16; // Read byte 2

value |= (uint32_t)SPI.transfer(0) << 8; // Read byte 1

value |= (uint32_t)SPI.transfer(0); // Read LSB

digitalWrite(CS_PIN, HIGH); // Deselect TMC2240

return value;

}

// Set motor current in milliamps

void setCurrent(uint16_t current) {

uint32_t ihold_irun = 0;

// Set hold current (current when motor is stationary)

ihold_irun |= ((current / 100) & 0x1F) << 0;

// Set run current (current when motor is moving)

ihold_irun |= ((current / 100) & 0x1F) << 8;

// Set hold delay (time before reducing to hold current)

ihold_irun |= ((current / 200) & 0x0F) << 16;

writeRegister(IHOLD_IRUN, ihold_irun);

}

// Set microstepping resolution (1, 2, 4, 8, 16, 32, 64, 128, 256)

void setMicrostepping(uint8_t microsteps) {

uint32_t chopconf = readRegister(CHOPCONF);

chopconf &= ~(0x0F << 24); // Clear MRES bits

// Convert microsteps to MRES register value

uint8_t mres;

switch (microsteps) {

case 256: mres = 0x0; break; // 1/256 microstepping

case 128: mres = 0x1; break; // 1/128 microstepping

case 64: mres = 0x2; break; // 1/64 microstepping

case 32: mres = 0x3; break; // 1/32 microstepping

case 16: mres = 0x4; break; // 1/16 microstepping

case 8: mres = 0x5; break; // 1/8 microstepping

case 4: mres = 0x6; break; // 1/4 microstepping

case 2: mres = 0x7; break; // 1/2 microstepping (half step)

case 1: mres = 0x8; break; // Full step

default: mres = 0x4; break; // Default to 1/16 microstepping

}

chopconf |= (mres << 24); // Set MRES bits

chopconf |= (1 << 28); // Enable interpolation

writeRegister(CHOPCONF, chopconf);

// Update global calculation variables

STEPS_PER_REVOLUTION = STEPS_PER_REV * microsteps;

currentAngleTolerance = calculateAngleTolerance(microsteps);

Serial.print("Microstepping set to 1/");

Serial.println(microsteps);

}TMC2240 communication relies on writeRegister() and readRegister() functions that handle SPI communication with the motor driver, while functions like setCurrent() and setMicrostepping() configure motor parameters by writing to specific hardware registers.

// Move motor a specified number of steps in the given direction

void moveMotor(bool direction, uint32_t steps) {

digitalWrite(DIR_PIN, direction); // Set direction pin

static unsigned long lastStepTime = 0;

static uint32_t stepsRemaining = 0;

// Initialize step counter on first call

if (stepsRemaining == 0) {

stepsRemaining = steps;

lastStepTime = millis();

}

// Generate step pulses at controlled speed

if (stepsRemaining > 0 && millis() - lastStepTime >= (1000 / currentSpeed)) {

digitalWrite(STEP_PIN, HIGH); // Start step pulse

delayMicroseconds(10); // Short pulse duration

digitalWrite(STEP_PIN, LOW); // End step pulse

stepsRemaining--; // Decrement remaining steps

lastStepTime = millis(); // Update timing

}

}

// Automatically move motor to target angle with precision control

void moveToAngle() {

if (!isMovingToAngle) return; // Exit if not in angle movement mode

// Calculate angular difference to target

float angleDifference = targetAngle - cachedCurrentAngle;

// Normalize angle difference to [-180, 180] range for shortest path

while (angleDifference > 180) angleDifference -= 360;

while (angleDifference < -180) angleDifference += 360;

// Check if target angle is reached within tolerance

if (abs(angleDifference) <= currentAngleTolerance) {

isMovingToAngle = false; // Stop angle movement mode

digitalWrite(STEP_PIN, LOW); // Ensure step pin is low

Serial.println("Target angle reached");

return;

}

// Set motor direction based on angle difference

currentDirection = (angleDifference > 0); // Positive = forward

digitalWrite(DIR_PIN, currentDirection);

// Enable motor if not already enabled

if (!isMotorEnabled) {

digitalWrite(EN_PIN, LOW); // Enable motor (active low)

isMotorEnabled = true;

}

// Dynamic speed control based on remaining angle

int stepDelay;

float absDiff = abs(angleDifference);

// Slower speeds as we approach target for better precision

if (absDiff <= 5.0) {

stepDelay = MIN_STEP_DELAY * 4; // Very slow for final approach

} else if (absDiff <= 20.0) {

stepDelay = MIN_STEP_DELAY * 2; // Slow for precision zone

} else if (absDiff <= 45.0) {

stepDelay = MIN_STEP_DELAY; // Normal speed

} else {

stepDelay = MIN_STEP_DELAY / 2; // Fast for large movements

}

// Take multiple steps toward target (up to 10 per loop iteration)

for (int i = 0; i < 10 && isMovingToAngle; i++) {

digitalWrite(STEP_PIN, HIGH); // Start step pulse

delayMicroseconds(stepDelay); // Pulse high time

digitalWrite(STEP_PIN, LOW); // End step pulse

delayMicroseconds(stepDelay); // Pulse low time

// Update current angle reading after each step

cachedCurrentAngle = (as5600.readAngle() * 360.0) / 4096.0;

angleDifference = targetAngle - cachedCurrentAngle;

// Re-normalize angle difference

while (angleDifference > 180) angleDifference -= 360;

while (angleDifference < -180) angleDifference += 360;

// Check if target reached during movement

if (abs(angleDifference) <= currentAngleTolerance) {

isMovingToAngle = false;

Serial.println("Target angle reached during movement");

break;

}

}

}

// Calculate angle tolerance based on microstepping resolution

float calculateAngleTolerance(uint8_t microsteps) {

// Calculate minimum angle step and multiply by 2 for tolerance

return (360.0 / (200.0 * microsteps)) * 2.0;

}Motion control functionality includes moveMotor() for generating step pulses for basic movement and moveToAngle() for precise positioning using encoder feedback. The system automatically adjusts movement speed based on the distance remaining to the target angle, using slower speeds for fine positioning and faster speeds for large movements.

Power management through the PD system negotiates appropriate power levels with USB-C sources, allowing the motor to receive optimal voltage ranging from 5V to 20V based on system requirements and source capabilities.

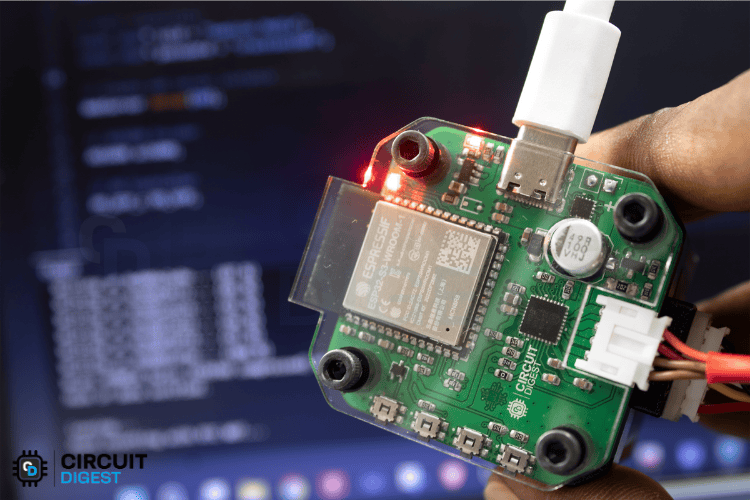

Firmware Upload and Web UI Testing

To begin, connect the custom PCB to your computer and upload the code using the Arduino IDE.

If you want to debug via Serial Monitor, don’t forget to enable the CDC (Communication Device Class) setting in the Arduino IDE under Tools > USB Mode before uploading the code.

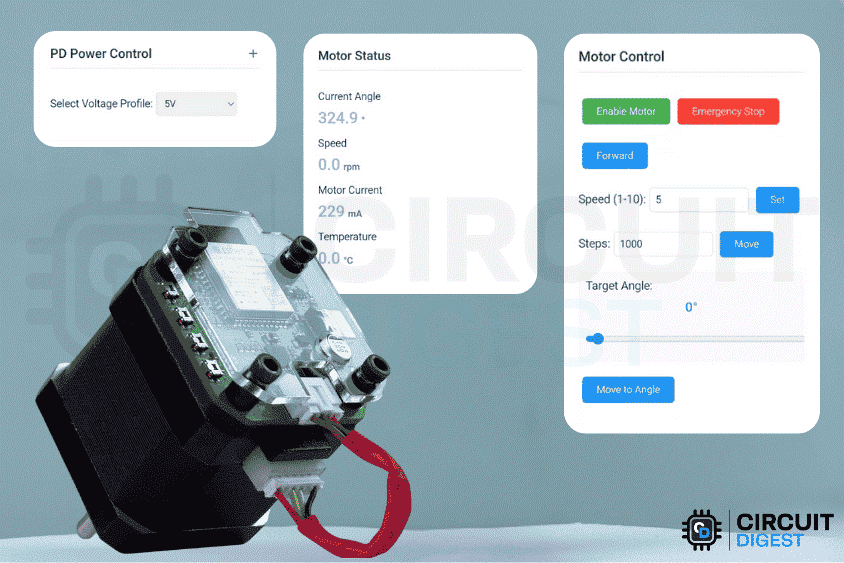

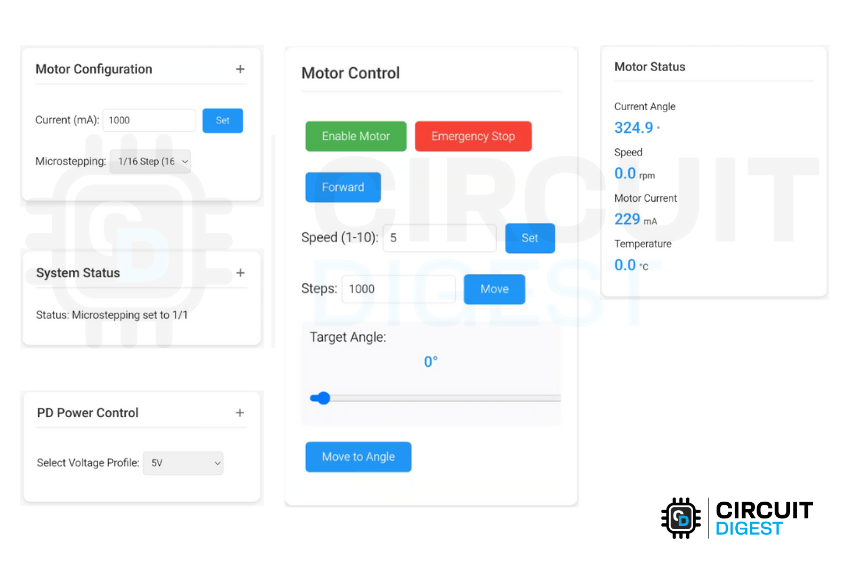

Now let's take a look at the UI. It is simple and self-explanatory.

There are a total of 5 cards,

Motor Configuration (Sets the motor's current (1000 mA) and microstepping mode (1/16 step))

PD Power Control (Selects voltage profile)

System Status (Shows the current system status, commands executed, etc.)

Motor Control (Provides operational controls with enable/disable buttons, emergency stop, directional movement options, speed adjustment, and positioning controls that allow movement by specific step counts or to target angles using either input fields or a slider interface.)

Motor Status (The right panel displays real-time status information, including the current motor angle, rotational speed (RPM), actual motor current draw (mA), and operating temperature.)

Above, you can see the User Interface of this Wireless Stepper motor controller project. which perfectly demonstrates esp32 stepper motor control wifi capabilities through a modern web interface.

Commonly Asked Questions on Wireless Stepper Motor Controller Project

⇥ Can I use a different stepper motor with this wireless controller?

Yes. Since the TMC2240 driver supports a large number of stepper motors, NEMA 17 and NEMA 23 are a couple of typical examples. You will simply have to adjust the current limit settings on the web interface of the controller from 100mA up to 2000mA to fit your motor specifications. In addition, you can also select microstepping for your motor through the web interface.

⇥ What types of power supply can it accommodate with the given ESP32 stepper controller?

This controller supports USB-C Power Delivery under the 5V to 20V category. It will negotiate for the voltage most suitable to run its wireless stepper motor driver, which will be any one of 5V/3A, 9V/3A, 12V/1.5A, 15V/2A, or 20V/1.5A.

⇥ Can I control multiple stepper motors with one ESP32?

This design was intended for a single ESP32 to control a single motor. To control multiple motors, you must use multiple wireless stepper motor controllers or redesign the circuit to have multiple TMC2240 drivers, each with its own SPI chip select pin.

⇥ What is the controllable range for a wireless stepper motor?

The wireless control range is limited by where the Wi-Fi signal is broadcast from. The range for an indoor setting is usually 30-100 meters, but for applications with longer distances and installations for industrial automation that require extended wireless coverage, it would make sense to use a Wi-Fi repeater or a mesh network.

⇥ How precise is the wireless stepper motor controller project?

The system is very precise with the 1/256 microstepping resolution, and closed loop feedback from the AS5600 encoder, and gives positioning accuracy of ±0.35 degrees for most applications of automation and robotics that require precision motor visibility

Stepper Motor Interfacing Projects

Explore other electronics projects and tutorials, covering circuit design, coding, and control techniques. These projects help you understand motor driver integration, speed control, and precise positioning for robotics and automation applications.

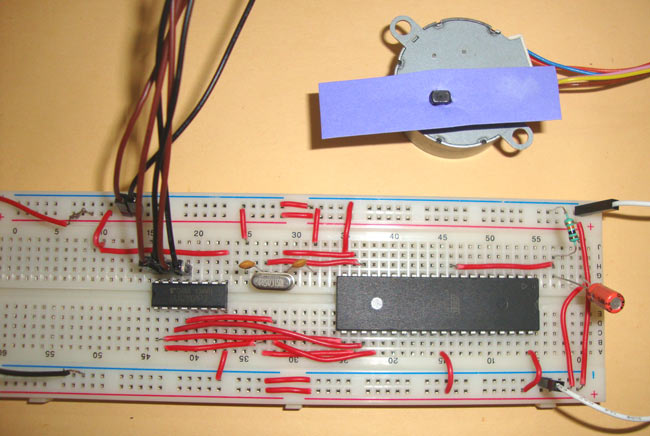

Stepper Motor Interfacing with 8051 Microcontroller

Learn how to control a stepper motor using the 8051 microcontroller (AT89S52) with detailed circuits, drive modes (wave, full-step, half-step), and troubleshooting tips—perfect for robotics, CNC, and automation applications.

Interfacing Stepper Motor with ARM7-LPC2148

Learn how to interface a unipolar stepper motor with the ARM7 LPC2148 microcontroller using the ULN2003 driver

Interfacing Stepper Motor with AVR Microcontroller Atmega16

In this tutorial we will interface 28BYJ-48 Stepper Motor with Atmega16 AVR Microcontroller using Atmel Studio 7.0. We will be interfacing the stepper motor with both the motor drivers i.e. ULN2003 and L293.

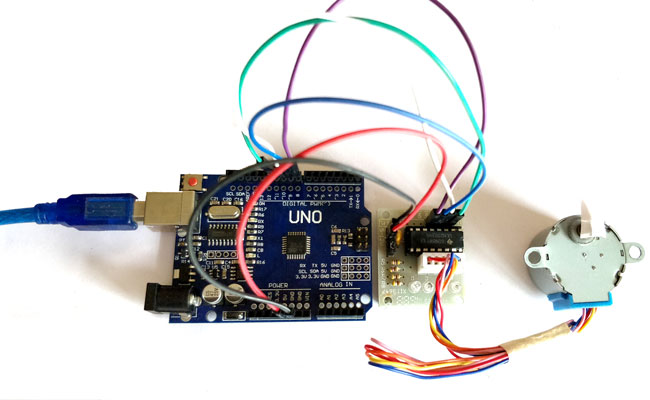

Arduino Stepper Motor Tutorial - Interfacing 28-BYJ48 Stepper Motor with Arduino Uno

In this Arduino stepper motor tutorial we will learn about the most commonly available stepper motor 28-BYJ48 and how to interface it with Arduino using ULN2003 stepper motor module.

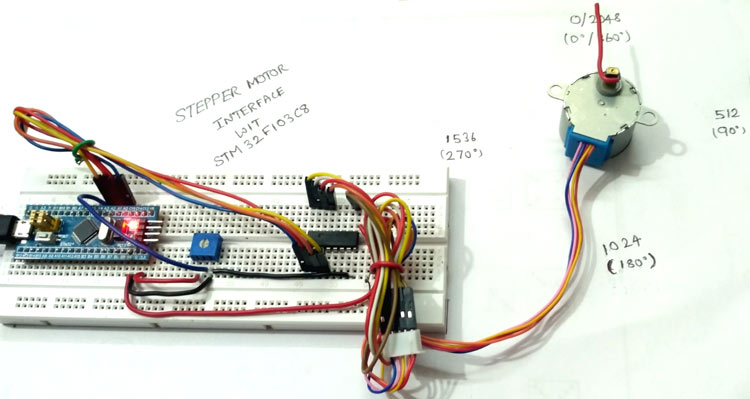

Interfacing Stepper Motor with STM32F103C8

Learn how to interface a 28BYJ-48 stepper motor with the STM32F103C8 (Blue Pill) using the ULN2003 driver IC. This tutorial covers circuit connections, potentiometer-based speed control, Arduino IDE programming, and stepper motor rotation in both clockwise and anticlockwise directions with practical examples.

Complete Project Code

/*

* ===============================================================================

* TMC2240 STEPPER MOTOR CONTROL WITH PD POWER DELIVERY & RGB STATUS INDICATORS

* ===============================================================================

*

* DESCRIPTION:

* This project implements a comprehensive stepper motor control system using the

* TMC2240 driver with advanced features including PD (Power Delivery) negotiation,

* magnetic encoder feedback, and RGB LED status indication.

*

* MAIN FEATURES:

* 1. TMC2240 Stepper Motor Driver Control

* - Configurable microstepping (1 to 256 steps)

* - Current control (up to 2A+)

* - SPI communication interface

* - Real-time temperature monitoring

*

* 2. USB-C Power Delivery (PD) Integration

* - FUSB302 PD controller support

* - Multiple voltage profiles (5V, 9V, 12V, 15V, 20V)

* - Automatic power negotiation

* - Real-time voltage/current monitoring

*

* 3. AS5600 Magnetic Encoder Integration

* - 12-bit resolution (4096 steps per revolution)

* - Absolute angle positioning

* - I2C communication

* - Precise angle-based motor control

*

* 4. RGB LED Status System

* - WiFi connection status indication

* - PD voltage level color coding

* - Motor state indication (enabled/disabled)

* - Web client connection status

*

* 5. Web-based Control Interface

* - Real-time motor control

* - Parameter adjustment (speed, current, microstepping)

* - System status monitoring

* - Emergency stop functionality

*

* 6. Advanced Motion Control

* - Absolute angle positioning

* - Dynamic speed control

* - Precision movement with tolerance

* - Direction control

*

* WORKING PRINCIPLE:

* The system operates by combining multiple control interfaces:

* - Web interface provides user control and monitoring

* - PD controller manages power delivery from USB-C source

* - TMC2240 drives the stepper motor with precise control

* - AS5600 provides position feedback for closed-loop control

* - RGB LED provides visual status feedback

*

* HARDWARE CONNECTIONS:

* - TMC2240: SPI interface (MOSI=11, MISO=13, SCK=12, CS=10)

* - AS5600: I2C interface (SDA=8, SCL=9)

* - FUSB302: Digital pin 7 for interrupt

* - RGB LED: Pins 40(R), 42(G), 41(B)

* - Motor Control: EN=14, STEP=5, DIR=6, UART_EN=15

*

* AUTHOR: [Rithik Krisna M]

* DATE: [28/05/2025]

* VERSION: 1.0

* ===============================================================================

*/

// ===============================================================================

// LIBRARY INCLUDES

// ===============================================================================

#include <SPI.h> // SPI communication for TMC2240

#include <WiFi.h> // WiFi connectivity

#include <WebServer.h> // HTTP server for web interface

#include "AS5600.h" // Magnetic encoder library - https://github.com/RobTillaart/AS5600

#include <Wire.h> // I2C communication

#include <PD_UFP.h> // USB-C Power Delivery library - https://github.com/kcl93/fusb302_arduino

#include <ArduinoJson.h> // JSON handling for web API - https://arduinojson.org/?utm_source=meta&utm_medium=library.properties // Version 7.4.1

#include "index_page.h" // HTML page for web interface

// ===============================================================================

// PIN DEFINITIONS

// ===============================================================================

#define FUSB302_INT_PIN 7 // Interrupt pin for PD controller

// WiFi Configuration

const char* ssid = "xxxx"; // WiFi network name

const char* password = "xxxx"; // WiFi password

// ===============================================================================

// OBJECT INSTANTIATION

// ===============================================================================

WebServer server(80); // Web server on port 80

AS5600 as5600; // Magnetic encoder object

PD_UFP_c PD_UFP; // Power Delivery controller object

// ===============================================================================

// POWER DELIVERY PROFILES CONFIGURATION

// ===============================================================================

// Structure to define PD power profiles with voltage, current, and name

struct PDProfile {

float voltage; // Voltage in volts

float current; // Current in amperes

const char* name; // Human-readable name

};

// Predefined PD power profiles for different voltage levels

const PDProfile pd_profiles[] = {

{5.0, 3.0, "5V/3A"}, // USB standard power

{9.0, 2.0, "9V/2A"}, // Quick charge level 1

{9.0, 3.0, "9V/3A"}, // Quick charge level 2

{12.0, 1.5, "12V/1.5A"}, // Low power 12V

{15.0, 2.0, "15V/2A"}, // Medium power 15V

{20.0, 1.5, "20V/1.5A"} // High voltage 20V

};

// ===============================================================================

// RGB LED CONFIGURATION

// ===============================================================================

// Pin definitions for RGB LED (common anode or cathode)

const int RGB_RED_PIN = 40; // Red LED pin

const int RGB_GREEN_PIN = 42; // Green LED pin

const int RGB_BLUE_PIN = 41; // Blue LED pin

// RGB color structure for easy color management

struct RGBColor {

int red; // Red component (0-255)

int green; // Green component (0-255)

int blue; // Blue component (0-255)

};

// Predefined color constants for different states

const RGBColor COLOR_OFF = { 0, 0, 0 }; // LED off

const RGBColor COLOR_RED = { 255, 0, 0 }; // Error/disconnected

const RGBColor COLOR_GREEN = { 0, 255, 0 }; // Connected/5V

const RGBColor COLOR_BLUE = { 0, 0, 255 }; // Waiting/9V

const RGBColor COLOR_YELLOW = { 255, 255, 0 }; // Connecting

const RGBColor COLOR_PURPLE = { 255, 0, 255 }; // 12V

const RGBColor COLOR_CYAN = { 0, 255, 255 }; // Special state

const RGBColor COLOR_WHITE = { 255, 255, 255 }; // Unknown/default

const RGBColor COLOR_ORANGE = { 255, 165, 0 }; // 15V

const RGBColor COLOR_PINK = { 255, 20, 147 }; // 20V

// ===============================================================================

// LED STATE MANAGEMENT VARIABLES

// ===============================================================================

unsigned long lastLEDUpdate = 0; // Last LED update timestamp

unsigned long ledBlinkInterval = 500; // Blink interval in milliseconds

bool ledBlinkState = false; // Current blink state (on/off)

RGBColor currentLEDColor = COLOR_OFF; // Current LED color

bool ledBlinkEnabled = false; // Blink enable flag

unsigned long lastClientRequest = 0; // Last web client request time

bool webClientConnected = false; // Web client connection status

bool pdColorModeActive = false; // PD color mode active flag

// ===============================================================================

// TMC2240 STEPPER DRIVER CONFIGURATION

// ===============================================================================

// SPI pin definitions for TMC2240 communication

const int MOSI_PIN = 11, MISO_PIN = 13, SCK_PIN = 12, CS_PIN = 10;

// Motor control pin definitions

const int EN_PIN = 14; // Enable pin (LOW = enabled, HIGH = disabled)

const int STEP_PIN = 5; // Step pulse pin

const int DIR_PIN = 6; // Direction pin (HIGH/LOW for CW/CCW)

const int UART_EN_PIN = 15; // UART enable pin (not used in SPI mode)

// ===============================================================================

// TMC2240 REGISTER ADDRESSES

// ===============================================================================

const uint8_t GCONF = 0x00; // General configuration register

const uint8_t CHOPCONF = 0x6C; // Chopper configuration register

const uint8_t IHOLD_IRUN = 0x10; // Current control register

const uint8_t TPOWERDOWN = 0x11; // Power down delay register

const uint8_t MSCNT = 0x6A; // Microstep counter register

const uint8_t MSCURACT = 0x6B; // Actual microstep current register

const uint8_t SG_RESULT = 0x40; // StallGuard result register

const uint8_t DRV_STATUS = 0x6F; // Driver status register

const uint8_t ADC_TEMP = 0x51; // Temperature ADC register

// ===============================================================================

// MOTOR CONFIGURATION CONSTANTS

// ===============================================================================

const uint16_t DEFAULT_CURRENT = 1000; // Default motor current in mA

const uint8_t DEFAULT_MICROSTEPS = 16; // Default microstepping setting

const uint16_t DEFAULT_SPEED = 5; // Default speed in steps/sec

const int STEPS_PER_REV = 200; // Steps per revolution (1.8° motors)

const int MIN_STEP_DELAY = 100; // Minimum delay between steps (μs)

// ===============================================================================

// GLOBAL STATE VARIABLES

// ===============================================================================

// Motor state variables

bool isMotorEnabled = false; // Motor enable state

bool currentDirection = true; // Current direction (true = forward)

bool isMovingToAngle = false; // Angle movement in progress flag

bool pd_negotiation_complete = false; // PD negotiation status

// Motor parameter variables

int currentSpeed = DEFAULT_SPEED; // Current speed setting

uint16_t motorCurrent = DEFAULT_CURRENT; // Current motor current setting

uint8_t microSteps = DEFAULT_MICROSTEPS; // Current microstepping setting

int STEPS_PER_REVOLUTION = STEPS_PER_REV * DEFAULT_MICROSTEPS; // Total steps per rev

// Position control variables

float targetAngle = 0.0; // Target angle for movement

float currentAngleTolerance = 0.0; // Current angle tolerance

float cachedCurrentAngle = 0.0; // Cached current angle reading

float cachedTemperature = 0.0; // Cached temperature reading

int cachedCurrentB = 0; // Cached current reading

// ===============================================================================

// TIMING CONTROL VARIABLES

// ===============================================================================

unsigned long lastStatusUpdate = 0; // Last status update timestamp

unsigned long lastEncoderUpdate = 0; // Last encoder update timestamp

unsigned long last_pd_check = 0; // Last PD check timestamp

unsigned long lastPDVoltageCheck = 0; // Last PD voltage check timestamp

// Timing intervals (in milliseconds)

const unsigned long STATUS_UPDATE_INTERVAL = 1000; // Status update every 1 second

const unsigned long ENCODER_UPDATE_INTERVAL = 100; // Encoder update every 100ms

const unsigned long PD_CHECK_INTERVAL = 100; // PD check every 100ms

const unsigned long CLIENT_TIMEOUT = 5000; // Web client timeout (5 seconds)

// Current PD profile index

int currentPDProfile = 0; // Default to the first profile (5V/3A)

// PD voltage check interval

const unsigned long PD_VOLTAGE_CHECK_INTERVAL = 100;

// ===============================================================================

// RGB LED CONTROL FUNCTIONS

// ===============================================================================

/**

* Set RGB LED to specified color

* @param color RGBColor structure with red, green, blue values

*/

void setRGBColor(RGBColor color) {

analogWrite(RGB_RED_PIN, color.red); // Set red component

analogWrite(RGB_GREEN_PIN, color.green); // Set green component

analogWrite(RGB_BLUE_PIN, color.blue); // Set blue component

currentLEDColor = color; // Update current color

}

/**

* Set RGB LED with individual color values

* @param red Red component (0-255)

* @param green Green component (0-255)

* @param blue Blue component (0-255)

*/

void setRGBColor(int red, int green, int blue) {

RGBColor color = { red, green, blue };

setRGBColor(color);

}

/**

* Turn off RGB LED and disable blinking

*/

void turnOffLED() {

setRGBColor(COLOR_OFF);

ledBlinkEnabled = false;

}

/**

* Enable LED blinking with specified color and interval

* @param color Color to blink

* @param interval Blink interval in milliseconds (default: 500ms)

*/

void enableLEDBlink(RGBColor color, unsigned long interval = 500) {

currentLEDColor = color;

ledBlinkInterval = interval;

ledBlinkEnabled = true;

ledBlinkState = false;

lastLEDUpdate = millis();

}

/**

* Update blinking LED state (call in main loop)

* Handles the timing and state changes for LED blinking

*/

void updateLEDBlink() {

if (!ledBlinkEnabled) return;

// Check if it's time to toggle the LED

if (millis() - lastLEDUpdate >= ledBlinkInterval) {

if (ledBlinkState) {

setRGBColor(COLOR_OFF); // Turn off LED

} else {

setRGBColor(currentLEDColor); // Turn on LED with current color

}

ledBlinkState = !ledBlinkState; // Toggle blink state

lastLEDUpdate = millis(); // Update last update time

}

}

/**

* Update status LED based on system state priority

* Priority: WiFi > PD Status > Client Connection

*/

void updateStatusLED() {

// Highest Priority: WiFi disconnected - Red fast blink

if (WiFi.status() != WL_CONNECTED) {

pdColorModeActive = false;

enableLEDBlink(COLOR_RED, 200); // Red fast blink for WiFi issues

return;

}

// Second Priority: PD is ready and negotiated - show voltage colors

if (PD_UFP.is_power_ready() && pd_negotiation_complete) {

// Only update PD colors periodically to avoid constant changes

if (millis() - lastPDVoltageCheck >= PD_CHECK_INTERVAL) {

updatePDVoltageColor();

lastPDVoltageCheck = millis();

}

return; // Exit here - PD colors are active

}

// Third Priority: WiFi connected but no PD - show connection status

pdColorModeActive = false;

// Update client connection status based on timeout

if (millis() - lastClientRequest > CLIENT_TIMEOUT) {

webClientConnected = false;

}

if (webClientConnected) {

// WiFi connected and web client active - Solid Green

setRGBColor(COLOR_GREEN);

ledBlinkEnabled = false;

} else {

// WiFi connected but no web client - Blue slow blink

enableLEDBlink(COLOR_BLUE, 1000);

}

}

/**

* Update LED color based on PD voltage level

* Different colors represent different voltage levels:

* Green=5V, Blue=9V, Purple=12V, Orange=15V, Pink=20V, Red=Unknown

*/

void updatePDVoltageColor() {

float voltage = pd_profiles[currentPDProfile].voltage; // Use selected profile voltage

RGBColor voltageColor = COLOR_WHITE; // Default for unknown voltage

// Determine color based on voltage range

if (voltage >= 4.5 && voltage < 6.0) {

voltageColor = COLOR_GREEN; // 5V - Green

} else if (voltage >= 8.5 && voltage < 10.0) {

voltageColor = COLOR_BLUE; // 9V - Blue

} else if (voltage >= 11.5 && voltage < 13.0) {

voltageColor = COLOR_PURPLE; // 12V - Purple

} else if (voltage >= 14.5 && voltage < 16.0) {

voltageColor = COLOR_ORANGE; // 15V - Orange

} else if (voltage >= 19.0 && voltage < 21.0) {

voltageColor = COLOR_PINK; // 20V - Pink

} else if (voltage > 0.0) {

voltageColor = COLOR_RED; // Unknown voltage - Red

} else {

voltageColor = COLOR_WHITE; // No voltage/not ready - White

}

// Set PD color mode active

pdColorModeActive = true;

// Set blink speed based on motor state

if (isMotorEnabled) {

enableLEDBlink(voltageColor, 200); // Fast blink when motor enabled

} else {

enableLEDBlink(voltageColor, 1000); // Slow blink when motor disabled

}

// Debug output for voltage color (can be removed in production)

if (voltageColor.red == COLOR_GREEN.red && voltageColor.green == COLOR_GREEN.green) Serial.print("GREEN");

else if (voltageColor.red == COLOR_BLUE.red && voltageColor.green == COLOR_BLUE.green) Serial.print("BLUE");

else if (voltageColor.red == COLOR_PURPLE.red && voltageColor.green == COLOR_PURPLE.green) Serial.print("PURPLE");

else if (voltageColor.red == COLOR_ORANGE.red && voltageColor.green == COLOR_ORANGE.green) Serial.print("ORANGE");

else if (voltageColor.red == COLOR_PINK.red && voltageColor.green == COLOR_PINK.green) Serial.print("PINK");

else if (voltageColor.red == COLOR_RED.red && voltageColor.green == COLOR_RED.green) Serial.print("RED");

else Serial.print("WHITE");

}

/**

* Update motor status color when motor state changes

*/

void updateMotorStatusColor() {

// Only update if PD is ready, otherwise let updateStatusLED handle it

if (PD_UFP.is_power_ready() && pd_negotiation_complete) {

updatePDVoltageColor();

}

}

/**

* Force immediate PD color update (call when motor state changes)

*/

void forceUpdatePDColors() {

if (PD_UFP.is_power_ready() && pd_negotiation_complete) {

lastPDVoltageCheck = 0; // Force immediate update

updatePDVoltageColor();

}

}

/**

* Initialize RGB LED pins and test sequence

*/

void initRGBLED() {

// Set pins as outputs

pinMode(RGB_RED_PIN, OUTPUT);

pinMode(RGB_GREEN_PIN, OUTPUT);

pinMode(RGB_BLUE_PIN, OUTPUT);

// Test sequence to verify LED functionality

setRGBColor(COLOR_RED);

delay(200);

setRGBColor(COLOR_GREEN);

delay(200);

setRGBColor(COLOR_BLUE);

delay(200);

turnOffLED();

Serial.println("RGB LED initialized");

}

// ===============================================================================

// TMC2240 DRIVER CONTROL FUNCTIONS

// ===============================================================================

// Function declarations for TMC2240 control

void configureDriver(); // Configure TMC2240 with default settings

void setCurrent(uint16_t current); // Set motor current

void setMicrostepping(uint8_t microsteps); // Set microstepping resolution

void writeRegister(uint8_t address, uint32_t value); // Write to TMC2240 register

uint32_t readRegister(uint8_t address); // Read from TMC2240 register

void updateCachedValues(); // Update cached sensor values

void moveMotor(bool direction, uint32_t steps); // Move motor specified steps

void moveToAngle(); // Move to target angle

float calculateAngleTolerance(uint8_t microsteps); // Calculate angle tolerance

// ===============================================================================

// MAIN SETUP FUNCTION

// ===============================================================================

void setup() {

// Initialize serial communication for debugging

Serial.begin(115200);

Serial.println("TMC2240 Stepper Motor Control");

// Initialize RGB LED system

initRGBLED();

// Initialize I2C for AS5600 encoder

Wire.setPins(8, 9); // Set custom I2C pins

Wire.begin();

// Initialize PD controller with 5V maximum initially

PD_UFP.init(FUSB302_INT_PIN, PD_POWER_OPTION_MAX_5V);

PD_UFP.set_power_option(PD_POWER_OPTION_MAX_5V);

// Initialize AS5600 magnetic encoder

as5600.begin(4); // Begin with direction pin 4

as5600.setDirection(AS5600_CLOCK_WISE);

// Check encoder connection

if (!as5600.isConnected()) {

Serial.println("Warning: AS5600 encoder not connected!");

}

// Initialize TMC2240 control pins

pinMode(EN_PIN, OUTPUT); // Motor enable pin

pinMode(STEP_PIN, OUTPUT); // Step pulse pin

pinMode(DIR_PIN, OUTPUT); // Direction control pin

pinMode(CS_PIN, OUTPUT); // SPI chip select pin

pinMode(MOSI_PIN, OUTPUT); // SPI master out, slave in

pinMode(MISO_PIN, INPUT); // SPI master in, slave out

pinMode(SCK_PIN, OUTPUT); // SPI clock pin

pinMode(UART_EN_PIN, OUTPUT); // UART enable (not used)

// Set initial pin states

digitalWrite(CS_PIN, HIGH); // Deselect TMC2240

digitalWrite(EN_PIN, HIGH); // Disable motor initially

digitalWrite(UART_EN_PIN, LOW); // Disable UART mode

digitalWrite(DIR_PIN, currentDirection); // Set initial direction

// Initialize SPI communication

SPI.begin(SCK_PIN, MISO_PIN, MOSI_PIN, CS_PIN);

// Connect to WiFi network

WiFi.begin(ssid, password);

Serial.print("Connecting to WiFi");

setRGBColor(COLOR_YELLOW); // Yellow while connecting

// Wait for WiFi connection

while (WiFi.status() != WL_CONNECTED) {

delay(500);

Serial.print(".");

}

Serial.println("\nConnected to WiFi");

Serial.print("IP Address: ");

Serial.println(WiFi.localIP());

setRGBColor(COLOR_GREEN); // Green when connected

delay(1000);

// ===============================================================================

// WEB SERVER ROUTE CONFIGURATION

// ===============================================================================

// Main page route - serves the web interface

server.on("/", HTTP_GET, []() {

lastClientRequest = millis();

webClientConnected = true;

server.send(200, "text/html", html_page);

});

// Motor enable route - enables the stepper motor

server.on("/enable", HTTP_GET, []() {

lastClientRequest = millis();

webClientConnected = true;

digitalWrite(EN_PIN, LOW); // Enable motor (active low)

isMotorEnabled = true;

updateMotorStatusColor(); // Update LED status

server.send(200, "text/plain", "Motor Enabled");

});

// Motor disable route - disables the stepper motor

server.on("/disable", HTTP_GET, []() {

lastClientRequest = millis();

webClientConnected = true;

digitalWrite(EN_PIN, HIGH); // Disable motor (active low)

isMotorEnabled = false;

updateMotorStatusColor(); // Update LED status

server.send(200, "text/plain", "Motor Disabled");

});

// Emergency stop route - immediately stops all motor activity

server.on("/stop", HTTP_GET, []() {

lastClientRequest = millis();

webClientConnected = true;

digitalWrite(EN_PIN, HIGH); // Disable motor

digitalWrite(STEP_PIN, LOW); // Ensure step pin is low

isMotorEnabled = false;

isMovingToAngle = false; // Stop angle movement

currentSpeed = DEFAULT_SPEED; // Reset speed

updateMotorStatusColor(); // Update LED status

String response = "{\"status\":\"Emergency Stop Activated\",\"motorEnabled\":false}";

server.send(200, "application/json", response);

Serial.println("EMERGENCY STOP ACTIVATED");

});

// Speed control route - sets motor speed

server.on("/speed", HTTP_GET, []() {

lastClientRequest = millis();

webClientConnected = true;

if (server.hasArg("value")) {

currentSpeed = server.arg("value").toInt();

server.send(200, "text/plain", "Speed set to " + String(currentSpeed));

}

});

// Manual movement route - moves motor by specified steps

server.on("/move", HTTP_GET, []() {

lastClientRequest = millis();

webClientConnected = true;

if (server.hasArg("steps")) {

int targetSteps = server.arg("steps").toInt();

moveMotor(currentDirection, targetSteps);

server.send(200, "text/plain", "Moving " + String(targetSteps) + " steps");

}

});

// System status route - returns current system status

server.on("/status", HTTP_GET, []() {

lastClientRequest = millis();

webClientConnected = true;

bool pd_ready = PD_UFP.is_power_ready();

float pd_voltage = (pd_ready && pd_negotiation_complete) ? PD_UFP.get_voltage() : 0.0;

float pd_current = (pd_ready && pd_negotiation_complete) ? PD_UFP.get_current() : 0.0;

String status = "{\"temperature\":" + String(cachedTemperature, 1) +

",\"current\":" + String(cachedCurrentB) +

",\"pd_ready\":" + String(pd_ready ? "true" : "false") +

",\"pd_negotiated\":" + String(pd_negotiation_complete ? "true" : "false") +

",\"pd_voltage\":" + String(pd_voltage, 2) +

",\"pd_current\":" + String(pd_current, 2) + "}";

server.send(200, "application/json", status);

});

// Motor current control route - sets motor current

server.on("/current", HTTP_GET, []() {

lastClientRequest = millis();

webClientConnected = true;

if (server.hasArg("value")) {

motorCurrent = server.arg("value").toInt();

setCurrent(motorCurrent);

server.send(200, "text/plain", "Motor current set to " + String(motorCurrent) + " mA");

}

});

// Microstepping control route - sets microstepping resolution

server.on("/microsteps", HTTP_GET, []() {

lastClientRequest = millis();

webClientConnected = true;

if (server.hasArg("value")) {

microSteps = server.arg("value").toInt();

setMicrostepping(microSteps);

server.send(200, "text/plain", "Microstepping set to 1/" + String(microSteps));

}

});

// Encoder status route - returns current encoder readings

server.on("/encoder", HTTP_GET, []() {

lastClientRequest = millis();

webClientConnected = true;

String json = String("{\"speed\":0") +

",\"rawAngle\":" + String(cachedCurrentAngle, 1) +

",\"current\":" + String(cachedCurrentB) + "}";

server.send(200, "application/json", json);

});

// Power status route - returns PD power status

server.on("/power_status", HTTP_GET, []() {

lastClientRequest = millis();

webClientConnected = true;

StaticJsonDocument<200> doc;

bool power_ready = PD_UFP.is_power_ready();

float voltage = 0.0;

float current = 0.0;

if (power_ready && pd_negotiation_complete) {

voltage = PD_UFP.get_voltage();

current = PD_UFP.get_current();

}

bool pd_connected = power_ready && pd_negotiation_complete && voltage > 0.0 && current > 0.0;

doc["pd_connected"] = pd_connected;

doc["pd_negotiated"] = pd_negotiation_complete;

if (pd_connected) {

doc["voltage"] = voltage;

doc["current"] = current;

doc["power"] = voltage * current;

}

String response;

serializeJson(doc, response);

server.send(200, "application/json", response);

});

// Direction control route - sets motor direction

server.on("/direction", HTTP_GET, []() {

lastClientRequest = millis();

webClientConnected = true;

if (server.hasArg("dir")) {

currentDirection = (server.arg("dir") == "true");

digitalWrite(DIR_PIN, currentDirection);

server.send(200, "text/plain", "Direction set to " + String(currentDirection ? "Forward" : "Backward"));

} else {

server.send(400, "text/plain", "Missing direction parameter");

}

});

// Angle positioning route - moves motor to specific angle

server.on("/set_angle", HTTP_GET, []() {

lastClientRequest = millis();

webClientConnected = true;

if (server.hasArg("angle")) {

targetAngle = server.arg("angle").toFloat();

currentAngleTolerance = calculateAngleTolerance(microSteps);

isMovingToAngle = true;

server.send(200, "text/plain", "Moving to angle " + String(targetAngle) + "° with accuracy ±" + String(currentAngleTolerance) + "°");

} else {

server.send(400, "text/plain", "Missing angle parameter");

}

});

// Web server endpoint to set Power Delivery (PD) profile

server.on("/setPD", HTTP_GET, []() {

// Update client activity tracking

lastClientRequest = millis();

webClientConnected = true;

// Check if profile parameter is provided in the request

if (server.hasArg("profile")) {

int profile = server.arg("profile").toInt(); // Get requested voltage profile

PD_power_option_t power_option; // Variable to store PD power option

// Map voltage profile to corresponding PD power option and profile index

switch (profile) {

case 5:

power_option = PD_POWER_OPTION_MAX_5V;

currentPDProfile = 0; // Index of 5V profile in pd_profiles[] array

break;

case 9:

power_option = PD_POWER_OPTION_MAX_9V;

currentPDProfile = 1; // Index of 9V profile in pd_profiles[] array

break;

case 12:

power_option = PD_POWER_OPTION_MAX_12V;

currentPDProfile = 2; // Index of 12V profile in pd_profiles[] array

break;

case 15:

power_option = PD_POWER_OPTION_MAX_15V;

currentPDProfile = 3; // Index of 15V profile in pd_profiles[] array

break;

case 20:

power_option = PD_POWER_OPTION_MAX_20V;

currentPDProfile = 4; // Index of 20V profile in pd_profiles[] array

break;

default:

// Invalid profile requested - send error response

server.send(400, "text/plain", "Invalid profile");

return;

}

// Apply the new power option to PD controller

PD_UFP.set_power_option(power_option);

// Run PD controller multiple times to ensure negotiation

for (int i = 0; i < 5; i++) {

PD_UFP.run(); // Process PD negotiation

delay(100); // Small delay between runs

}

// Force immediate LED color update to reflect new voltage

forceUpdatePDColors();

// Send success response to client

server.send(200, "text/plain", "PD profile set to " + String(profile) + "V");

} else {

// No profile parameter provided - send error response

server.send(400, "text/plain", "Missing profile parameter");

}

});

// Start the web server

server.begin();

Serial.println("HTTP server started");

// Configure the TMC2240 stepper motor driver

configureDriver();

}

// Main program loop - runs continuously

void loop() {

// Handle incoming web server requests

server.handleClient();

// Run PD controller to maintain power negotiation

PD_UFP.run();

// Update LED blinking animation if enabled

updateLEDBlink();

// Update status LED periodically (every 100ms) to avoid constant updates

static unsigned long lastStatusLEDUpdate = 0;

if (millis() - lastStatusLEDUpdate >= 100) {

updateStatusLED(); // Update LED based on system status

lastStatusLEDUpdate = millis();

}

// Handle Power Delivery controller status checks

if (millis() - last_pd_check >= PD_CHECK_INTERVAL) {

bool was_negotiated = pd_negotiation_complete; // Store previous state

// Check if PD power is ready/negotiated

if (PD_UFP.is_power_ready()) {

if (!pd_negotiation_complete) {

// Power negotiation just completed

Serial.println("PD Power Negotiation Complete!");

pd_negotiation_complete = true;

// Force immediate LED color update to show new voltage

lastPDVoltageCheck = 0;

}

} else {

if (pd_negotiation_complete) {

// Power negotiation was lost

Serial.println("PD Power Negotiation Lost!");

pd_negotiation_complete = false;

pdColorModeActive = false; // Disable PD color mode

}

}

last_pd_check = millis(); // Reset check timer

}

// Update cached sensor values periodically

if (millis() - lastEncoderUpdate >= ENCODER_UPDATE_INTERVAL) {

updateCachedValues(); // Update angle, temperature, current readings

lastEncoderUpdate = millis();

}

// Handle automatic angle-based motor movement

if (isMovingToAngle) {

moveToAngle(); // Continue moving motor to target angle

}

// Print system status to serial monitor periodically

if (millis() - lastStatusUpdate >= STATUS_UPDATE_INTERVAL) {

Serial.println("System Status: Motor " + String(isMotorEnabled ? "Enabled" : "Disabled") +

", Temp: " + String(cachedTemperature, 1) + "°C" +

", WiFi: " + String(WiFi.status() == WL_CONNECTED ? "Connected" : "Disconnected") +

", Web Client: " + String(webClientConnected ? "Active" : "Inactive") +

", PD Mode: " + String(pdColorModeActive ? "Active" : "Inactive"));

lastStatusUpdate = millis();

}

}

// Configure TMC2240 stepper driver with default settings

void configureDriver() {

// Set motor current and microstepping to default values

setCurrent(DEFAULT_CURRENT);

setMicrostepping(DEFAULT_MICROSTEPS);

// Set power down delay to 0 (immediate power down when idle)

writeRegister(TPOWERDOWN, 0x0000);

// Enable step interpolation for smoother movement

uint32_t gconf = readRegister(GCONF);

gconf |= (1 << 1); // Set interpolation bit

writeRegister(GCONF, gconf);

// Set chopper off time (TOFF) to 5 for proper operation

uint32_t chopconf = readRegister(CHOPCONF);

chopconf &= ~(0x0F << 0); // Clear TOFF bits

chopconf |= (5 << 0); // Set TOFF to 5

writeRegister(CHOPCONF, chopconf);

Serial.println("TMC2240 configured with default settings");

}

// Set motor current in milliamps

void setCurrent(uint16_t current) {

uint32_t ihold_irun = 0;

// Set hold current (current when motor is stationary)

ihold_irun |= ((current / 100) & 0x1F) << 0;

// Set run current (current when motor is moving)

ihold_irun |= ((current / 100) & 0x1F) << 8;

// Set hold delay (time before reducing to hold current)

ihold_irun |= ((current / 200) & 0x0F) << 16;

writeRegister(IHOLD_IRUN, ihold_irun);

}

// Set microstepping resolution (1, 2, 4, 8, 16, 32, 64, 128, 256)

void setMicrostepping(uint8_t microsteps) {

uint32_t chopconf = readRegister(CHOPCONF);

chopconf &= ~(0x0F << 24); // Clear MRES bits

// Convert microsteps to MRES register value

uint8_t mres;

switch (microsteps) {

case 256: mres = 0x0; break; // 1/256 microstepping

case 128: mres = 0x1; break; // 1/128 microstepping

case 64: mres = 0x2; break; // 1/64 microstepping

case 32: mres = 0x3; break; // 1/32 microstepping

case 16: mres = 0x4; break; // 1/16 microstepping

case 8: mres = 0x5; break; // 1/8 microstepping

case 4: mres = 0x6; break; // 1/4 microstepping

case 2: mres = 0x7; break; // 1/2 microstepping (half step)

case 1: mres = 0x8; break; // Full step

default: mres = 0x4; break; // Default to 1/16 microstepping

}

chopconf |= (mres << 24); // Set MRES bits

chopconf |= (1 << 28); // Enable interpolation

writeRegister(CHOPCONF, chopconf);

// Update global calculation variables

STEPS_PER_REVOLUTION = STEPS_PER_REV * microsteps;

currentAngleTolerance = calculateAngleTolerance(microsteps);