Switching Mode Power Supply, or simply SMPS, is a type of Power Supply Unit (PSU) that uses a switching device (such as a transistor or MOSFET) to convert the source, which can be AC or DC, to a constant DC voltage. Switched-mode power supply circuits (SMPS) are most often required in many electronic designs to convert the AC mains voltage to a suitable level of DC voltage for the device to operate. This comprehensive guide demonstrates how to design a 12V 27W SMPS circuit using the UC3843 current-mode PWM controller IC. This type of AC-DC converter takes in the 230V/110V AC mains voltage as input and converts it to low-level DC voltage with the help of the switching process, hence the name switch-mode power supply. This UC3843 application circuit diagram converts standard 220-240V AC mains voltage into stable 12V DC through precisely controlled high-frequency switching and magnetic energy transfer.

This comprehensive tutorial covers every aspect of the UC3843 SMPS schematic, including circuit theory, component selection criteria, UC3843 IC SMPS circuit pinout configuration, custom transformer design and winding procedures, PCB layout considerations, testing methodology, and troubleshooting techniques. We have already built a few SMPS circuits earlier, like a 5V 2A SMPS circuit and a 12V 1A TNY268 SMPS circuit. We even did a project on how to build our own SMPS transformer that could be used in our SMPS designs, along with the driver IC. In this project, we will build another 12V 2.2A SMPS circuit using the UC3843 Current Mode PWM Controller IC, which is a popular low-cost SMPS driver IC. This tutorial will take you through the complete UC3843 SMPS circuit diagram and will also explain how to build your transformer for the UC3843 circuit. Interesting, right? Let's get started.

Table of Contents

UC3843 IC Pinout Configuration and Pin Function

The SMPS circuit with UC3843 IC pinout utilises an 8-pin DIP (Dual Inline Package) or SOIC (Small Outline Integrated Circuit) configuration. Understanding each pin's specific function is essential for successful circuit implementation. The following table provides comprehensive pin descriptions:

| Pin Number | Pin Name | Detailed Function |

| Pin 1 | COMP | Compensation pin - Error amplifier output requiring external RC network for loop stability and frequency compensation |

| Pin 2 | VFB | Voltage Feedback - Inverting input to error amplifier, connects to optocoupler for isolated feedback from secondary side |

| Pin 3 | ISENSE | Current Sense input - Monitors primary current via sense resistor, provides cycle-by-cycle overcurrent protection (1V threshold) |

| Pin 4 | RT/CT | Oscillator Timing - External resistor and capacitor set switching frequency (typical range: 20kHz to 500kHz) |

| Pin 5 | GND | Ground Reference - Connect directly to power ground with minimal trace resistance for stable operation |

| Pin 6 | OUT | Output Driver - High-current totem-pole output (±1A capability) drives external power MOSFET gate |

| Pin 7 | VCC | IC Power Supply - Requires 8.5V minimum for startup, 7.9V UVLO threshold, typical operation: 10-30V |

| Pin 8 | VREF | Voltage Reference - Precision 5.0V ±0.25V output (50mA max), powers timing circuit and feedback network |

UC3843 Based SMPS Design Specifications

The UC3843 is a fixed frequency-mode PWM controller, it is specially designed for Off-Line and DC to DC converter applications with minimum external components. These integrated circuits feature a trimmed oscillator for precise duty cycle control, a temperature-compensated reference, a high-gain error amplifier, a current-sensing comparator, and a high-current totem pole output for driving a Power MOSFET. As we will see, it makes it suitable for many different applications.

Input specification: Our UC3843 SMPS circuit will work in the AC-to-DC conversion domain. So, the input is AC. In this project, the input voltage is fixed. It is as per the European standard voltage rating. So, the input AC voltage of this SMPS will be 220-240VAC. It is also the standard voltage rating of India.

Output specification: We will set the output voltage to 12V with a 2.2A current rating. Thus, it will be 27W output. This SMPS will provide a constant voltage irrespective of the load current; it will work in CV (Constant Voltage) mode. Also, the output voltage will be fixed at 12V rated. This UC3843 application circuit diagram implements Constant Voltage (CV) control mode operation, automatically maintaining a stable 12V output voltage across the entire load current range from zero (no-load) to the maximum rated 2.2A current draw.

Protection circuits: There are various protection circuits that can be used to design an SMPS circuit, to make the operation safe and reliable. The protection circuit protects the SMPS as well as the associated load. Depending on the type, the protection circuit can be connected across the input or output. For this SMPS, input surge protection will be used with a maximum operating input voltage of 275VAC. Also, to deal with EMI issues, a common-mode filter will be used to blank out the generated EMI. On the Output side, we will include short circuit protection, over-voltage protection, and over-current protection. Other than that, to reduce EMI and noise, we can use spark gaps, or we can use

UC3843 Internal Circuit Operation and Control Theory

As we have discussed earlier, we will be using the popular UC3843 IC to design our SMPS, but before we do that, we need to understand the basic working of the IC. In this section, we will clarify some aspects of it. If you want to learn more, you can check out the datasheet of the UC3843 IC.

Under-voltage lockout: When the input voltage of the power supply drops below the rated/configured voltage, the UVLO detection voltage kicks in, and the UVLO sets the internal circuit to a semi-standby state to prevent any damage to the circuit. When the power supply voltage rises and becomes higher than the UVLO release voltage, and the normal operation continues during Under-Voltage Lock-Out, the output driver is biased to a high impedance state. Pin 6 should be shunted to the ground with a bleeder resistor to prevent activating the power switch with output leakage current.

Error Amp Configuration: There are two error amps in this circuit. These two can be configured to sense voltage and current. To configure the current, you can use the formula.

Peak current (IS) is determined by the formula.

![]()

A small RC filter may be required to suppress switch transients.

Oscillator Waveforms and Maximum Duty Cycle: Oscillator timing capacitor, CT, is charged by VREF through RT and discharged by an internal current source. During the discharge time, the internal clock signal blanks the output to the low state. The selection of RT and CT, therefore, determines both oscillator frequency and maximum duty cycle. Charge and discharge times are determined by the formulas:

Now, we know the UC3843 IC a little better, so we can move to designing the SMPS with it.

Components Required to Build the UC3843 Based 27 Watt SMPS Circuit

The components required to build the UC3843 Based 27 Watt SMPS Circuit are listed below. We designed this circuit with very generic components, which makes the replication process very easy.

- Power Connector -1

- 1A TR5-370 Fuse -1

- MOV 275V -1

- 1N4007 Diode -4

- 100uF/450V Capacitor -2

- Common Mode Choke -1

- 18K,2W -2

- FR107 Diode -2

- 10K Resistor -4

- 22pF/100pF Capacitor -10 or 2

- 150K Resistor - 1

- 104 pF -1

- 4.7K Resistor -2

- 224 pF -1

- 100uF, 25V - 2

- 223pF -2

- 22R -1

- 1K Resistor -1

- 0.5R, 3W Resistor -1

- SR360 Diode - 2

- 3.3uF Inductor - 2

- 100uF Capacitor -2

- EL-35 Core and Bobbin - 1 (Salvaged From an ATX Power Supply)

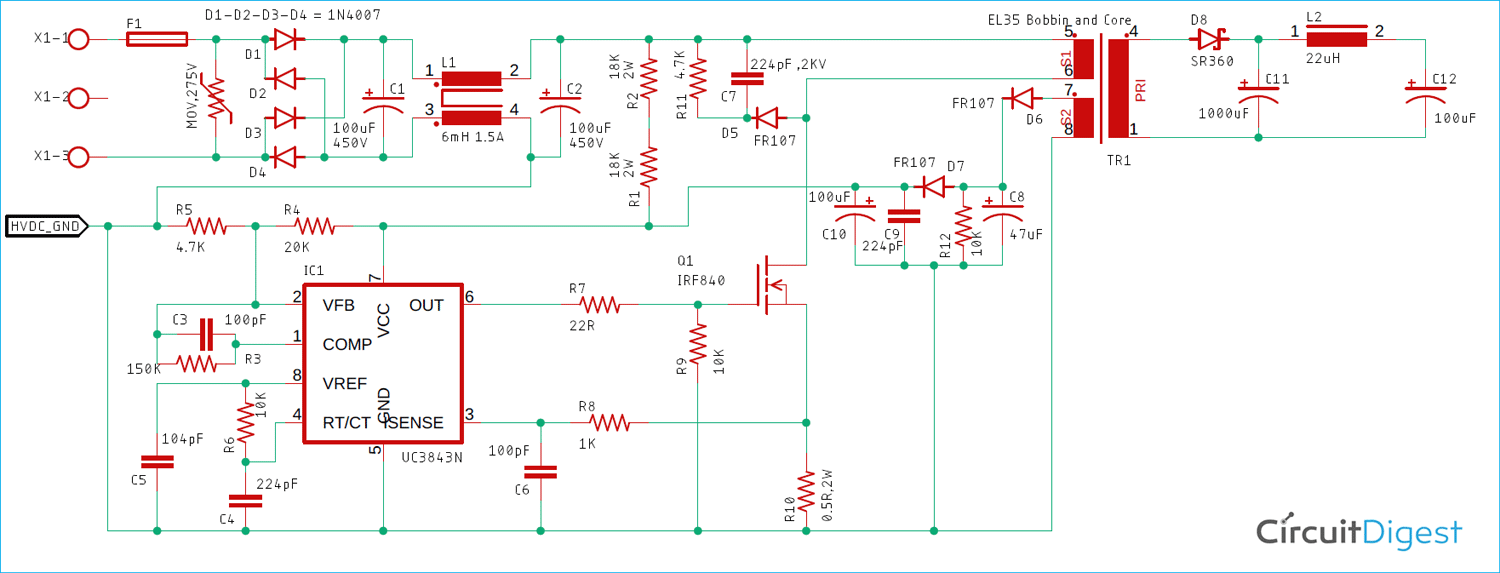

Detailed UC3843 SMPS Circuit Schematic Analysis

The comprehensive UC3843 application circuit diagram shown below is designed using the application note from the semiconductor, and I tweaked some component values according to my needs because I already had those in my stockpile.

Before we build the circuit, it's better to understand the circuit operation. In this section, we will do just that.

Input surge and SMPS fault protection:

This section consists of two components, F1 and MOV. F1 is a 1A 250VAC slow blow fuse, and MOV is a 7mm 275V MOV (Metal Oxide Varistor). During a high voltage surge (more than 275VAC), the MOV becomes dead short and blows the input Fuse. However, due to the slow blow feature, the fuse withstands inrush current through the SMPS.

AC-DC Conversion:

The AC-DC conversion is done using four 1N4007 Diodes that make up a full bridge rectifier. A 1N4007is a 1000V 1A-rated rectifier diode. The filtering is done using the 100uF 400V capacitor. However, for such a 25W circuit, a 22uF 400V is sufficient.

PI Filter:

Different states have different EMI rejection standards. This design confirms the EN61000-Class 3 standard, and the PI filter is designed in such a way as to reduce the common-mode EMI rejection. This section is created using C1, C2, and L1. C1 and C2 are 10uF, 400V.The startup subsystem in this UC3843 IC SMPS circuit diagram utilises two high-value startup resistors (R1 and R2, each 18kΩ 2W rating) connected in series between the high-voltage DC bus and the UC3843 VCC pin (Pin 7).

Driver Circuitry or Switching Circuit:

For this design, the UC3843 alongside the IRF840 MOSFET forms the driver circuit to at initial startup some power is needed to start the operation, and the two resistors R1 and R2 comes in those are called the Startup Resistors these startup resistors provide the initial startup current to startup the circuit, and when the circuit is switching and it's on the auxiliary winding provides the power required.

Clamp Circuit :

The transformer is an inductor across the power driver MOSFET. Therefore, when the transformer turns off, it creates a huge voltage spike. If not compensated correctly, it could easily kill the MOSFET, which is why a clamp circuit becomes necessary. Thus, the C7, R11, and D5 make up the clamp circuit.

Auxiliary Winding:

The Auxiliary winding provides power to the IC while it is in full operating condition. The power from the auxiliary winding is converted and filtered to DC using D6, D7, C8, C9, C10, and R12.

Secondary Rectifier and Snubber Circuit:

We need to convert the output of the Transformer to DC before we can connect our application circuits. An SR360 Schottky rectifier diode is used, as the output current is 2A; SR360 is a 3A 60V-rated Schottky diode.

Filter Section:

C6 is the filter capacitor. It is a low ESR capacitor for better ripple rejection. Also, an LC post-filter is used, where L2 and C7 provide better ripple rejection across the output.

Oscillator Frequency Selection:

The frequency of the UC3843 IC can be adjusted according to needs. For our case, the Frequency of the IC is set to 80KHz with the help of the R6 Resistor and C4 capacitor. An additional C5 capacitor is used to filter the power. For this UC3843 SMPS schematic, these components are specifically selected to generate an 80kHz ±5% switching frequency, representing an engineering optimum for 20-50W power level designs.

Construction of Switching Transformer for UC3843 Based 27 Watt SMPS Circuit

Let's now build the Switching Transformer. To do so, we will use the information provided in the UC3843 Application Note.

The Core is based on an EL35 bobbin and core with an air gap of 0.5mm. The primary inductance is 1mH. To build this transformer, the following materials are needed.

- Polyester Tape

- EL35 Core pairs with 0.5mm air gap.

- 26 AWG copper wire

- 30 AWG copper wire

- Horizontal Bobbin (Salvaged from ATX Power Supply)

- Inductance Meter

⇒ Step 1: Primary Winding Procedure (45 Turns, 26 AWG)

Hold the core in one hand and start with the 26AWG wire with pin 1, make 45 turns in a clockwise direction around the bobbin and finish it off at pin 7. Finally, apply a layer of tape.

⇒ Step 2: Auxiliary Bias Winding Implementation (10 Turns, 30 AWG)

Start the bias winding using 30AWG wire from pin 3 and make 10 turns in a clockwise direction, and finish it on pin 5. Once done, apply three layers of polyester tape.

⇒ Step 3: Secondary Output Winding Configuration (9 Turns, 26 AWG)

Start the secondary winding on the opposite side of the bobbin from pin1 and make 9 clockwise turns, and finish it off on pin3. And apply 3 layers of tape.

⇒ Step 4: Core Assembly and Mechanical Securing

Secure the transformer with superglue/ duct tape to reduce vibrations and noise in the transformer.

⇒ Step 5: Electrical Verification and Inductance Testing

Once that is done, measure the primary inductance of the transformer, and if it's close to 1mH, you are done building the transformer at this point.

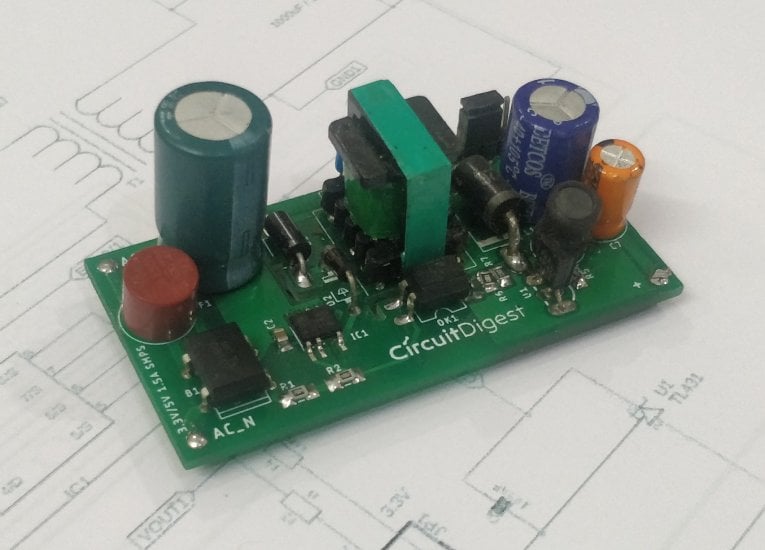

Building the UC3843 Based 27 Watt SMPS Circuit

With the custom-wound flyback transformer completed and electrically verified, proceed to final circuit assembly following the complete UC3843 SMPS circuit diagram schematic. With the Switching Transformer, we constructed the circuit on a perf board and according to the given circuit diagram. Once all the soldering process was finished, the board looked like the image shown below.

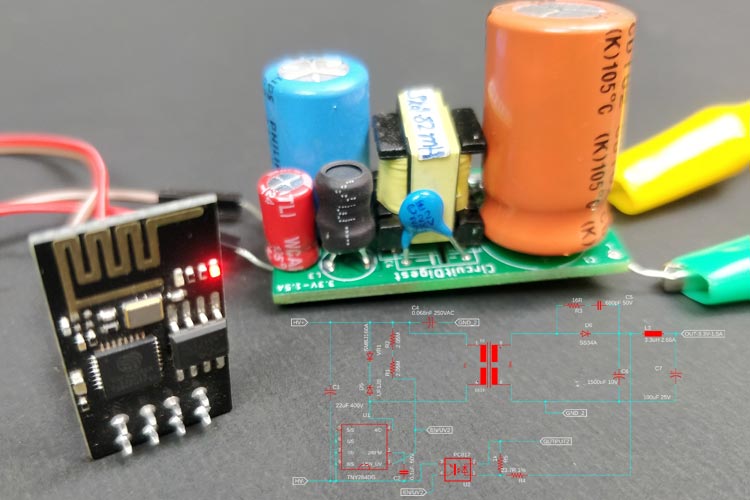

UC3843 Based SMPS Circuit Testing

To test the circuit, we connect the input to the supply AC, and we connect the output to the multimeter. As you can see, we have 243V as input and 12.43V as output.

The output voltage is a little bit more than 12V due to tolerances, but when a load is attached, the voltage is stable and working.

Practical Application and Use Cases

This professionally designed 12V 27W SMPS circuit has a number of practical applications in consumer electronics, industrial automation, telecommunications and embedded systems.

» LED Lighting: It provides a power source for constant-voltage LED strip lighting (12V for 5050/5630 SMD LEDs), LED panels for architectural lighting, landscape lighting transformers, RGB LED controllers and for high-brightness LED arrays (up to 2.2A continuous). The fixed 12V output ensures uniform brightness in the LED panel and prevents LED overdrive failure due to unexpected voltage changes.

» Embedded systems/development platforms: Provides power for microcontroller development boards (Arduino Mega, STM32 Discovery), single-board computers needing 12V input with onboard voltage regulators, FPGA evaluation boards, and embedded Linux platforms; the extremely low-noise output and excellent load regulation work well for sensitive analog measurement applications.

» Automotive electronics and mobile installations: Powers car audio amplifiers (up to 25W RMS output), automotive dash cameras and driving recorders, GPS navigation and car accessories, mobile radio transceivers (CB, amateur radio, or commercial two-way radio equipment), and automotive accessory equipment. The broad input voltage range can be used under international voltage standards.

» Battery Charging Applications: These are the basis for 12V lead-acid battery charger circuits (automotive, motorcycle, UPS backup batteries) when utilised in conjunction with appropriate charging control circuitry (current limiting, temperature compensation, float voltage regulation). It may also be used for charging lithium-ion/LiFePO4 battery packs when fitted with a suitable battery management system (BMS).

» Security and Surveillance Systems: Provides power to CCTV cameras (up to 2x 12V 1A cameras from a single supply), DVR/NVR recording equipment, PIR motion sensors, magnetic door/window contacts, and access control systems (card readers, electromagnetic locks), and alarm panel control circuits. Reliable, uniform 12V output keeps security systems functioning in consumer and commercial environments.

» Telecom and Networking: This includes powering VoIP (Voice-over-IP) telephone systems, small office networking equipment (switches/routing equipment) that are 12V input compatible, commercial intercom systems, wireless access points, and DSL/cable modems. Low EMI conducted/radiated EMI minimises problems with cartridges and other sensitive communications circuits.

Industrial

» Control and Automation: Powers proximate sensors (inductive, capacitive, photoelectric), pneumatic solenoid valves, industrial control relays, PLC input/output modules, process instrumentation transducers, and small industrial actuators. Safety features against overvoltage, overcurrent, and short-circuits provide reliable operation in an industrial environment.

» Test and Measurement Equipment: Acts as a bench power supply for electronics hobbyists, as an educational laboratory power supply for universities and technical colleges, as a portable field service power supply for technicians, and in general, as an adjustable voltage supply (adding only a minor circuit modification of a voltage adjustment potentiometer).

Systematic Troubleshooting Guide and Common Issues

| Symptom / Problem | Probable Causes | Steps and Solutions |

| Complete absence of output voltage | • Catastrophic MOSFET failure (short-circuit or open-circuit) • No VCC supply reaching UC3843 IC • Blown input fuse • Open-circuit transformer winding • Incorrect optocoupler installation (polarity) • Faulty UC3843 IC | Measure DC bus voltage (should be ~310V); Check MOSFET with multimeter diode test mode (should show diode drop drain-to-source in one direction); Verify VCC voltage at Pin 7 (should reach 8.5V at startup); Test transformer winding continuity; Replace suspected defective components systematically |

| Output voltage significantly low (<10V) | • Incorrect feedback resistor divider values • Heavy secondary winding loading/excessive resistance • Insufficient input AC voltage • Wrong transformer turns ratio • Excessive duty cycle limitation | Recalculate and verify feedback resistor values using TL431 equations; Measure secondary winding DC resistance (should be <0.2Ω); Verify AC input measures 220-240V; Recount transformer turns; Measure duty cycle with oscilloscope (should be 40-60% under normal load) |

| Excessive output ripple voltage (>150mV) | • Insufficient output capacitance • High ESR (dried out) electrolytic capacitors • Defective or missing LC output filter • Poor PCB layout with excessive trace inductance | Replace output filter capacitors with fresh low-ESR types (<100mΩ); Verify output inductor value and saturation current rating; Measure capacitor ESR with ESR meter; Add additional ceramic capacitors (100µF-220µF X7R) in parallel; Improve PCB layout minimizing loop areas |

| Audible high-frequency noise/squealing | • Loose or improperly secured transformer core • Component resonance at switching frequency • Defective capacitors with internal resonance • Magnetostriction in transformer core • PCB resonance vibration | Reapply adhesive to transformer core ensuring tight mechanical bond; Change switching frequency slightly (±5kHz) using different RT/CT values; Replace suspect capacitors; Apply polyurethane conformal coating or transformer varnish to dampen mechanical vibrations; Mount PCB with vibration-damping standoffs |

| MOSFET excessive heating or thermal failure | • Missing or inadequate heatsink • Excessive duty cycle causing continuous conduction • Inadequate or failed RCD clamp circuit • Wrong MOSFET (insufficient voltage rating) • Poor PCB thermal design | Install properly sized heatsink (minimum 10°C/W for IRF840); Apply thermal interface compound correctly; Verify MOSFET voltage rating >500V for 240V AC input; Check clamp circuit components (R-C-D network) for correct values and functionality; Measure MOSFET drain voltage with oscilloscope ensuring voltage spikes remain <450V peak; Increase copper area under MOSFET for heat spreading |

| UC3843 IC fails to initiate switching | • Incorrect startup resistor values (too high resistance) • UVLO circuit fault or incorrect VCC voltage • Damaged IC from ESD or overvoltage • Missing or incorrect oscillator components (RT/CT) • Output shorted preventing startup | Verify startup resistors provide 8-10mA charging current to VCC; Measure VCC voltage during startup (should reach >8.5V); Replace potentially damaged IC; Verify RT and CT component values and connections; Disconnect output load during troubleshooting; Check for short-circuits on output stage |

| Erratic or unstable output voltage | • Insufficient feedback loop compensation • Broken optocoupler or TL431 failure • Loose or intermittent component connections • Damaged feedback trace or poor solder joint • EMI coupling into feedback circuit | Redesign compensation network (RC from Pin 1 to ground); Test optocoupler and TL431 functionality in isolation; Perform thorough visual inspection and mechanical stress testing; Resolder all feedback circuit connections; Add shielding or filtering to feedback path; Verify proper grounding techniques |

| Intermittent shutdown or restart cycling | • Thermal protection activating (IC or MOSFET) • Overcurrent limiting engaging repeatedly • Loose transformer connections • Auxiliary supply voltage inadequate • Input voltage borderline for UVLO | Monitor component temperatures with IR thermometer or thermal camera; Reduce load current and verify stable operation; Check current sense resistor value (may be too low); Verify all transformer terminal connections secure; Measure auxiliary supply voltage under all conditions (should maintain >9V); Increase input voltage if marginal |

Frequently Asked Questions (FAQs) - UC3843 SMPS Circuit Design

⇥ Q1: What are the differences between UC3842 and UC3843 PWM controllers?

UC3843 has a reduced startup threshold voltage of 8.5V (turn-on) and 7.9V UVLO (turn-off) as opposed to UC3842's considerably higher 16V startup and 10V UVLO thresholds. This renders UC3843 even better suited for applications with low auxiliary supply voltage or self-powered circuits where lower voltage operation is desirable. Both ICs have 100% maximum duty cycle capability (compared to 50% for UC3844/3845 versions).

⇥ Q2: How is slope compensation used, and under what conditions is it used in UC3843 circuits?

Slope compensation eliminates sub-harmonic oscillation instability in current-mode PWM converters with duty cycles greater than 50%. It is implemented by adding a small artificial ramp voltage (0.5-1.0V peak) to the current sense signal at Pin 3, stabilising the inner current control loop. If you do not have slope compensation and perform duty cycles greater than 50%, oscillations at 1/2 the switching frequency can cause severe instability, bad regulation, and even damage components under certain loads.

⇥ Q3: In a UC3843 SMPS, how can I provide current limit/short circuit protection?

UC3843 offers internal cycle-by-cycle current limiting: as Pin 3 (ISENSE) voltage reaches the 1.0V level, the IC instantly shuts down that switching cycle. Primary protection: Calculate the current sense resistor to produce a 1V drop at the desired maximum primary current (usually 120-150% of normal full-load current). Secondary protection: Include a TL431-based secondary-side overcurrent detection circuit sensing output current via a sense resistor; optocoupler relays fault signal to primary side, triggering shutdown with automatic restart (hiccup mode) for reliable short-circuit protection.

⇥ Q4: What is the maximum duty cycle UC3843 achieves for SMPS applications?

UC3843 can claim 100% duty cycle, theoretically, but most SMPS designs limit the duty cycle to 80- 90%, to allow adequate switch turn-off times for the MOSFET (“S”) to prevent core saturation of the transformer, for appropriate current sensing, and so that energy transfer to the secondary may operate stably. Duty cycle is automatically modulated by feedback controls based on input voltage and load conditions (duty cycle or duty cycle variation may change currently).

⇥ Q5: Why does my UC3843 SMPS have high output ripple voltage?

Too much ripple generally signifies low output filter capacitance, poor capacitors with high ESR (>100mΩ), or poor LC post-filtering. Fix: Employ high-quality low-ESR electrolytic capacitors with ratings <50mΩ ESR in parallel with ceramic capacitors (100µF X7R); Include a good LC filter with ferrite core inductors; Check for capacitors that have not dried out (replace every 2-3 years in hot climates). Goal: <50mV peak-to-peak ripple full load.

⇥ Q6: What methods may be implemented to eliminate audible noise from the transformer in the UC3843 SMPS design?

Curing the transformer core halves together using cyanoacrylate glue or epoxy helps to eliminate magnetostriction motion while also preventing mechanical vibration. Providing a consistent spacing of 0.5mm air gaps and clean mating surfaces. Operating the SMPS design at a frequency above 60kHz moves the acoustic emissions to a range outside of human hearing (20Hz - 20kHz). Coating the transformer windings with polyurethane varnish or a conformal coating will dampen vibrations. If there is whistling perceptible to adjacent users, a small adjustment of +/ -5kHz should alleviate some of the frequency variation associated with it.

⇥ Q7: Under what conditions does the UC3843 IC go into thermal shutdown protection?

Thermal shutdown engages when the internal junction temperature is above around 150°C, resulting from high power dissipation (>1W), poor heatsinking/thermal management, or high ambient temperatures. Fixes: Lower switching frequency from 100kHz to 60-80kHz; Expand PCB copper area beneath IC for heat spreading; Provide good ventilation and airflow; Check current sense resistor is not generating excessive Pin 3 voltage (>0.8V), adding unnecessary internal dissipation.

Conclusion

We sincerely hope this informative guide on the UC3843 application circuit diagram - complete with an SMPS circuit with UC3843 IC pinout - has meaningfully enriched your understanding of practical switched-mode power supply design, including magnetic component design, feedback control systems, electromagnetic interference/electromagnetic compatibility (EMI/EMC), and practical debugging strategies. The detailed UC3843 SMPS circuit diagram, step-by-step instructions on custom transformer construction, and ample performance characterisation are more than enough for engineers, technicians, students and hobbyists to recreate the project, or modify the design to accommodate different specifications (different output voltages, power levels and different input voltage ranges).

The complete testing process is shown at the bottom of the page. If you have any questions about the UC3843 IC SMPS circuit diagram, component substitutions, variations in the design to accommodate different specifications, optimal winding of your transformer, and/or troubleshooting help from the construction, please ask your question in the comment section below.

Projects Related to SMPS Circuits

Explore innovative projects related to SMPS circuits, showcasing efficient power conversion techniques and practical designs for voltage regulation. Learn how different SMPS topologies improve performance, efficiency, and compactness in modern electronic systems.

Build Your Own 5V, 1A Adjustable SMPS Using a Dead Computer ATX Power Supply

in this article, we will show you how you can build a 5V, 1A SMPS circuit by salvaging parts from an old throwaway PC ATX power supply.

Design your own Compact 5V/3.3V SMPS Circuit for Embedded and IoT Projects

Hence, in this article, we will learn how to build an SMPS circuit that can either output 5V or 3.3V (hardware configurable using a jumper). The circuit design and PCB layout are also provided, so you can simply port this into your existing design.

Design and Build a Compact 3.3V/1.5A SMPS Circuit for Space Constraint Applications

To build this SMPS circuit on PCB, we had our PCB boards from PCBWay, and we assembled and tested the same in this tutorial session.