Relay logic control systems are truly a foundation of industrial automation, and electromagnetic relays are necessary to perform switching actions in these conversion systems. The relay logic circuits also utilise relays along with switches, motors, timers, actuators, and contactors to form ON/OFF control systems effectively. Though relay logic control proves to be effective with fundamental operations, it demands complex wiring when compared to contemporary PLC systems. This extensive guide delves into relay logic control examples, circuit symbols, operation principles, and functional relay logic diagram applications.

Quick Overview

Duration: 1-2 hours | Type: Digital Logic | Difficulty: Beginner-Intermediate

Technical Scope:

Relay logic, circuit symbols

Use Cases:

Industrial automation, safety interlocking

Table of Contents

- How Relay Logic Control Systems Work

- Relay Logic Diagram- Schematic/Symbols

- Standard Relay Logic Symbols

- Relay Logic Circuit Examples and Analysis

- Basic Relay Logic Gate

- Relay Logic Control vs PLC Systems

- Advanced Relay Logic Control Applications

- └ NAND Gate Relay Logic Configuration

- └ NOR Gate Relay Logic Configuration

- Frequently Asked Questions

- Practical Relay Applications

How Relay Logic Control Systems Work: Fundamental Principles

Relay acts as a switch which is operated by a small amount of current. The relay has two contacts-

- Normally open (NO)

- Normally Closed (NC)

In the figure given below, you can see there are two sides of a Relay. One is the primary coil, which acts as an electromagnet when current passes through it, and the other is the secondary side, having NO and NC contacts.

When the contact position is Normally Open, the switch is Open, and hence the circuit is Open and no current flows through the circuit. When the contact position is normally closed, the switch is closed and the circuit is completed and hence current flows through the circuit.

This change of state in the contacts occurs whenever a small electrical signal is applied, i.e. whenever a small amount of current flows through the relay, the contact changes.

This is explained through the figures below-

The above figure shows the switch in the NO contact position. In this figure, the primary circuit (coil) is not completed, and hence no current flows through the electromagnetic coil in that circuit. Therefore, the connected bulb remains off as the relay contact remains open.

Now, the above figure shows the switch in the NC contact position. In this figure, the primary circuit (coil) is closed, so there is some current through the coil connected in that circuit. Due to the current flowing in this electromagnetic coil, a magnetic field is created in its vicinity, and due to this magnetic field, the relay is energised and hence closes its contacts. Therefore, the connected bulb turns ON.

You can find the detailed article on Relay here and learn how Relay can be used in any circuit.

Relay Logic Diagram- Schematic/Symbols

A relay logic circuit is a schematic diagram which shows various components, their connections, inputs as well and outputs in a particular fashion. In relay logic circuits, the contacts NO and NC are used to indicate a Normally Open or a Normally Closed relay circuit. It contains two vertical lines, one on the extreme left and the other on the extreme right. These vertical lines are called rails. The extreme left rail is at the supply voltage potential and is used as an input rail. The extreme right rail is at zero potential and is used as the output rail. Professional relay logic diagrams utilise standardised symbols to represent circuit components.

Particular symbols are used in relay logic circuits to represent different circuit components. Some of the most common and widely used symbols are given below-

1. NO contact

The given symbol indicates a Normally Open contact. If the contact is normally open, it would not allow any current to pass through it, and hence, there will be an Open circuit at this contact.

2. NC contact

This symbol is used to indicate a Normally Closed contact. This allows the current to pass through it and acts as a short circuit.

3. Push Button (ON)

This push button allows current to flow through it to the rest of the circuit as long as it is pressed. If we release the push button, it becomes OFF and no longer allows the current to flow. This means that to carry the current, the push button has to remain pressed.

4. Push Button (OFF)

The OFF push button indicates an open circuit, i.e. it does not allow the flow of current through it. If the push button is not pressed, it stays in the OFF state. It can transition into the ON state to carry the current through it once it is pressed.

5. Relay coil

The relay coil symbol is used to indicate a control relay, motor starter, contactor, or timer.

6. Pilot Lamp

The given symbol denotes a pilot lamp, also known as a bulb. They indicate the machine operation.

Standard Relay Logic Symbols

Symbol Type | Function | Application in Relay Logic Control |

|---|---|---|

NO Contact | Normally Open Switch | Allows current flow when energised |

NC Contact | Normally Closed Switch | Blocks current flow when energised |

Push Button (ON) | Momentary Contact | Temporary circuit activation |

Push Button (OFF) | Break Contact | Emergency stops and safety circuits |

Relay Coil | Electromagnetic Actuator | Control element in relay logic circuits |

Pilot Lamp | Visual Indicator | Status indication and system feedback |

Relay Logic Circuit Examples and Analysis

The working of a relay logic circuit example can be explained through the given figures.

This figure shows a basic relay logic circuit. In this circuit,

Rung 1 contains one Push button (initially OFF) and one control relay.

Rung 2 contains one Push button (initially ON) and one Pilot lamp.

Rung 3 contains one NO contact and one Pilot lamp.

Rung 4 contains one NC contact and one pilot lamp.

Rung 5 contains one NO contact, one pilot lamp and a sub-rung with one NC contact.

To understand the working of the given relay logic circuit, consider the figure below

In rung 1, the push button is off, and hence it does not allow the current to pass through it. Therefore, there is no output through rung 1.

In rung 2, the push button is on and therefore, current passes from the high voltage rail to the low voltage rail and the Pilot Lamp 1 glows.

In rung 3, the contact is Normally Open; therefore, Pilot lamp 2 remains off, and there is no flow of current or output through the rung.

In rung 4, the contact is normally closed, thereby allowing the current to pass through it and giving an output to the low-voltage rung.

In rung 5, no current flows through the main rung as the contact is normally Open, but due to the presence of the sub-rung, which contains a normally closed contact, there is a flow of current, and hence the pilot lamp 4 glows.

Basic Relay Logic Gate

These relay logic gate setups illustrate how mechanical contacts can carry out complex logic operations, providing the foundation for sophisticated relay logic control systems in industrial applications. These relay logic gate examples provided an assurance of understanding Boolean logic principles visually. Basic digital logic gates can also be realised using relay logic and have a simple construction using the contacts as given below:

1. OR Gate – Truth table for OR gate is as shown

A | B | O/P |

0 | 0 | 0 |

0 | 1 | 1 |

1 | 0 | 1 |

1 | 1 | 1 |

This table is realised using the relay logic circuit in the following manner

In this, the Pilot lamp will turn on whenever any one of the inputs becomes one, which makes the contact associated with that input normally closed. Otherwise, the contact remains normally open.

2. AND Gate – The Truth table for the AND gate is given as –

A | B | O/P |

0 | 0 | 0 |

0 | 1 | 0 |

1 | 0 | 0 |

1 | 1 | 1 |

Relay logic realisation of the AND gate is given by –

The contacts are connected in series for the AND gate. This means that the pilot lamp will turn ON if and only if both the contacts are normally closed, i.e. when both the inputs are 1.

3. NOT Gate – The Truth table for the NOT gate is given by –

A | O/P |

0 | 1 |

1 | 0 |

The equivalent relay logic circuit for the given NOT gate truth table is as follows –

The pilot lamp lights up when the input is 0, so that the contact remains normally closed. As the input changes to 1, the contact changes to normally Open and hence the pilot lamp doesn’t light up, giving the output as 0.

4. NAND Gate – The NAND gate truth table is as follows –

A | B | O/P |

0 | 0 | 1 |

0 | 1 | 1 |

1 | 0 | 1 |

1 | 1 | 0 |

The relay logic circuit, as realised for the given truth table, is as –

As two normally closed contacts are connected in parallel, the pilot lamp lights up when one or both of the inputs are 0. However, if both the inputs become 1, both the contacts become Normally Open and hence the output becomes 0, i.e. the pilot lamp doesn’t light up.

5. NOR Gate – The truth table for the NOR gate is given by the following table –

A | B | O/P |

0 | 0 | 1 |

0 | 1 | 0 |

1 | 0 | 0 |

1 | 1 | 0 |

The given truth table can be implemented using the relay logic as follows –

Here, two normally closed contacts are connected in series, which means the pilot lamp will light up only if both the inputs are 0. If any one of the inputs becomes 1, that contact changes to normally open and hence the flow of current is interrupted, thereby causing the pilot lamp not to light up, indicating 0 output.

Relay Logic Control vs PLC Systems: Key Comparisons

Aspect | Relay Logic Control | PLC Systems |

|---|---|---|

Wiring Complexity | Extensive hardwired connections | Simplified wiring with software logic |

Implementation Time | Longer installation and testing | Faster programming and deployment |

Maintenance | Physical contact inspection required | Software diagnostics available |

Flexibility | Limited - requires rewiring for changes | High - software modifications possible |

Fault Detection | Manual troubleshooting necessary | Automated error reporting |

Cost Effectiveness | Lower initial cost for simple applications | Better value for complex systems |

Advanced Relay Logic Control Applications

NAND Gate Relay Logic Configuration

The NAND gate performs an inverted AND function that is important for creating complete relay logic circuit examples. This is represented with parallel NC contacts so that we can get the expected output for the provided truth table.

NOR Gate Relay Logic Configuration

NOR gates in relay logic control use a series connection of NC contacts, providing an output when both of its inputs have been considered inactive. This application is critical when dealing with the safety interlocking of industrial relay logic diagrams.

Frequently Asked Questions on Relay Logic Control

⇥ What constitutes relay logic control, and how does it work?

Relay logic control consists of electromagnetic relays that are employed for switching circuits in industrial automation. When voltage is applied to its coil, the relay induces an electromagnetic field that causes contact movement to give accurate ON/OFF control of the devices being controlled-from motors to lights and actuators.

⇥ What are the major elements in relay logic circuit examples?

Key components include electromagnetic relays, with NO/NC contacts, push buttons, pilot lamps, timers, contactors, and control switches, as various industrial applications and process control dishes are provided for by the logical interconnection of these elements between supply and return rails.

⇥ How do you read relay logic diagrams proficiently?

In relay logic diagrams, the vertical rails stand for the voltage supply on the left and the return on the right, and horizontal rungs interrupt this voltage with various circuit elements. Each horizontal rung forms an independent circuit, uses standardised symbols, and is then abbreviated for the contacts, coils, and loads considered. Understanding what each symbol means allows for analysing and eventually troubleshooting the circuit.

⇥ When does one choose a relay logic control system over PLCs?

Relay logic would be picked in simple applications where the cost factor is very important, where only standard ON/OFF control is required and a minimum logic arrangement. Conversely, PLCs are used in complex systems that require constant changes, advanced diagnostics, communication, and complex control algorithms using large amounts of I/O.

⇥ What are some disadvantages of relay logic control systems?

They include rigorous wiring, time-consuming implementation, are difficult to maintain, are less adaptable to changes, are challenging to detect faults, are less accurate than PLC systems, and have higher operating costs in the long run for complicated control applications.

Practical Relay Applications in Real-World Electronics Projects

Experience the power of relay-based control systems through a range of hands-on projects that bring theory into practice. From motion-activated AC switching to Arduino-powered motor control and relay interfacing, these examples showcase how relays can be effectively integrated into automation and embedded systems for precise switching, safety, and performance optimization.

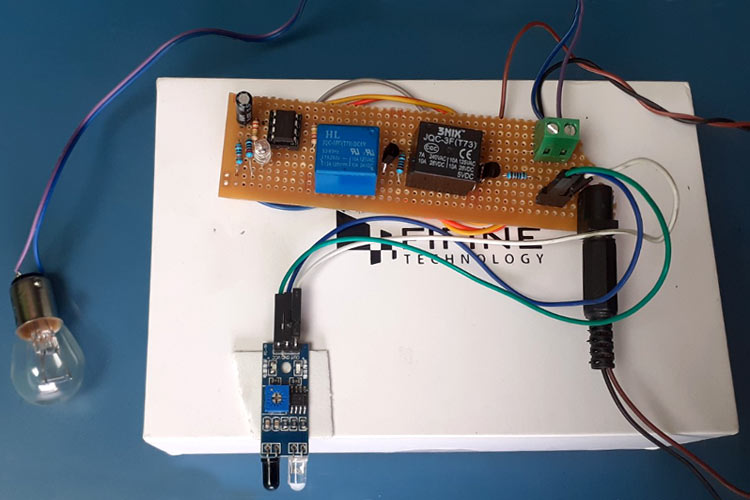

IR based Motion Sensor Circuit using 555 Timer IC

In this project tutorial, we are going to use an IR sensor with a NE555 Timer IC to detect motion and switch the AC load according to that.

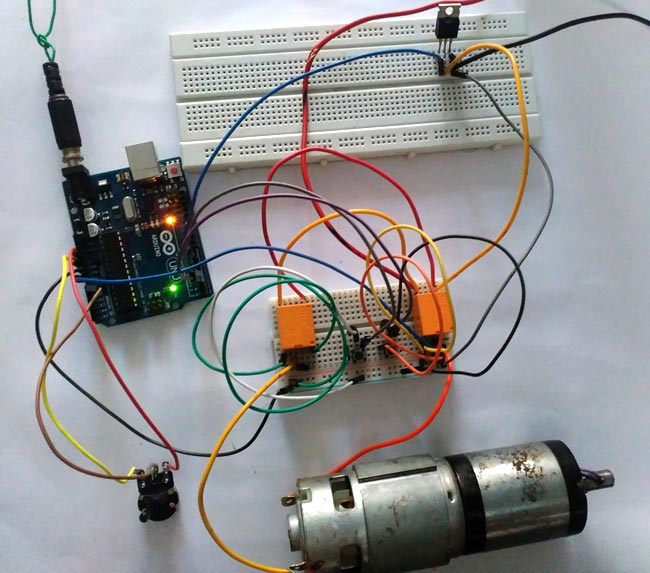

Arduino DC Motor Speed and Direction Control using Relays and MOSFET

In this project we control direction and speed of a 24v high current motor using Arduino and two relays. No power switches are needed for this circuit, just two push buttons and in Potentiometer to control the direction and speed of DC Motor.

Interfacing Relay Module with Arduino

This article will explore the workings of a relay module and provide a detailed guide on how to interface a single channel relay module with an Arduino.