The next generation of computer chips may not come from factories on Earth, but from satellites circling the planet. A UK company’s successful test of a 1,000°C furnace in space is bringing that futuristic vision closer to reality. Space Forge, a startup based in Cardiff, Wales, has confirmed that its microwave sized orbital furnace was successfully switched on and reached the temperature required for semiconductor production, a crucial milestone in proving that advanced manufacturing processes can function in space.

Semiconductor fabrication on Earth is highly complex and resource intensive, but space offers unique advantages. In microgravity atoms within semiconductor materials can align more evenly, while the vacuum environment significantly reduces the risk of impurities entering the wafer. According to Space Forge, these conditions could result in chips that are far more efficient and reliable than current terrestrial alternatives. The company claims that its in-space process could produce semiconductors up to 4,000 times purer than those manufactured on Earth with applications ranging from 5G infrastructure and electric vehicle charging systems to advanced aerospace technologies.

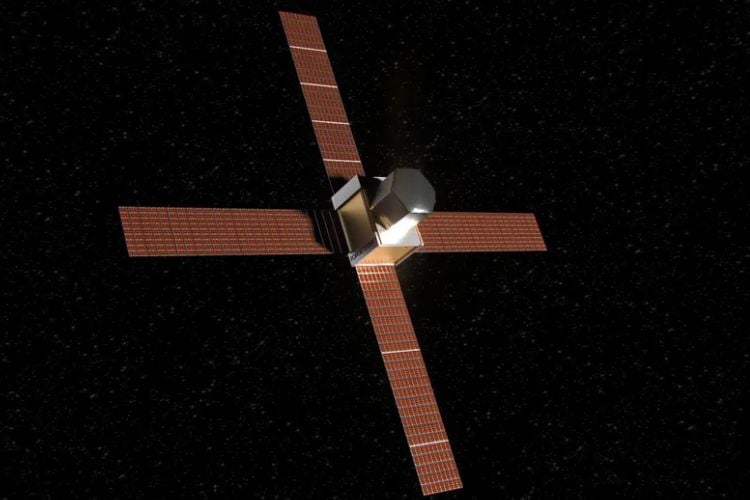

The furnace test follows Space Forge’s first satellite launch in June 2025 aboard a SpaceX Transporter-14 mission, though it took several months to successfully activate the system, highlighting the technical challenges involved. Despite this, the company plans to scale up its efforts by developing a larger orbital factory capable of producing up to 10,000 chips, alongside solutions to safely return the finished products to Earth. While space-based manufacturing could reduce the heavy demand for power and water on Earth, experts note that the environmental impact of frequent rocket launches will remain a key factor in determining how viable this bold new approach truly becomes.