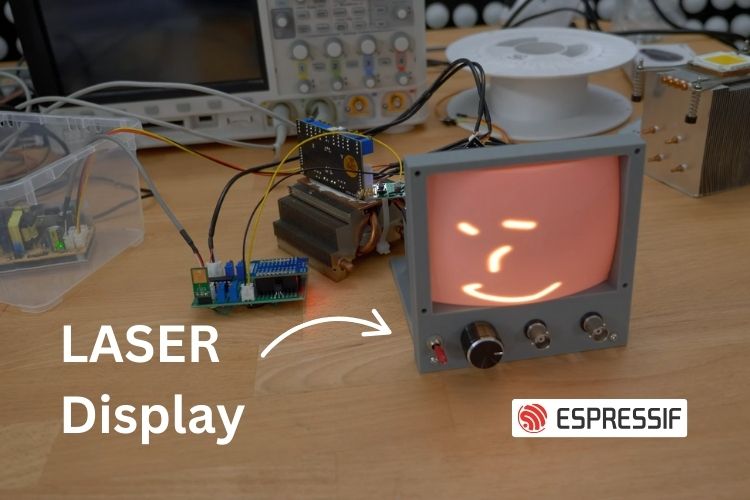

A developer has built a laser galvo-based vector display featuring a custom signal conditioning and thermal management system that leverages a low-cost galvanometer for high-speed vector rendering. The design replaces traditional stepper motor-driven systems with a faster galvanometer that requires a ±15V drive signal. To achieve this, a custom op-amp-based amplifier was implemented to scale the ESP32 DAC’s limited 0-3.3V output, ensuring the galvo receives the correct voltage for full deflection.

The choice of the ESP32 microcontroller was driven by its robust digital processing capabilities and versatility, despite its inherent voltage limitations. A switching regulator was added to step down a 12V supply to a stable 5V, providing the necessary power for reliable operation. This careful signal conditioning is critical for precise vector display performance, as it allows the system to maintain accurate control over the galvanometer’s movement.

Integration of a laser module is managed via a dedicated ESP32 GPIO pin, synchronizing laser activation with the vector data to produce clear and accurate displays. Additionally, thermal management plays a vital role in the system. The high-power amplification and galvo driver generate significant heat, so heatsinks were employed to ensure stable performance during continuous operation.

To mitigate mechanical stress caused by high deflection angles, a wide-angle lens was proposed. This solution effectively increases the display size without overloading the galvo, balancing the electrical requirements with mechanical constraints. Overall, the technical choices made in this project—spanning power management, signal amplification, and thermal control—highlight a sophisticated approach to modern vector display technology.