Nowadays, the world is shifting towards electrified mobility to reduce the pollutant emissions caused by nonrenewable fossil-fueled vehicles and to provide an alternative to pricey fuel for transportation. But for electric vehicles, travelling range and the charging process are the two major issues affecting their adoption over conventional vehicles. Wireless charging systems for electric vehicles solve two fundamental problems: limited driving range and long charging times that slow mass EV adoption. With new wireless EV charging systems technology, drivers will no longer have to feed the meter and wait for hours at charging stations. Simply park your vehicle at defined charging designated areas, or your garage, or travel and charge it with dynamic wireless charging technology.

With the introduction of the wireless EV charging system, no more waiting at charging stations for hours; now get your vehicle charged by just parking it in a parking spot or by parking at your garage or even while driving, you can charge your electric vehicle. As of now, we are very much familiar with wireless transmission of data, audio and video signals, so why can’t we transfer power over the Air?

Thanks to the great scientist Nikola Tesla for his limitless, amazing inventions, in which wireless power transfer is one of them. He started his experiment on wireless power transmission in 1891 and developed the Tesla coil. In 1901, with the primary goal of developing a new wireless power transmission system, Tesla started developing the Wardenclyffe Tower for a large high-voltage wireless energy transmission station. The saddest part is to satisfy Tesla's debts, the tower was dynamited and demolished for scrap on July 4th 1917

Table of Contents

How Wireless EV Charging Systems Work

The wireless EV charging system project operates on the same fundamental principle as transformer technology. Here's the complete process:

| Component | Function | Technology |

| AC Supply | Converts 220V 50Hz to high-frequency AC | Power Electronics |

| Transmitter Coil | Creates alternating magnetic field | Electromagnetic Induction |

| Receiver Coil | Captures magnetic field energy | Mutual Induction |

| Compensation Networks | Maintains resonance frequency | LC Circuits |

| Rectifier & BMS | Converts AC to DC for battery | Power Management |

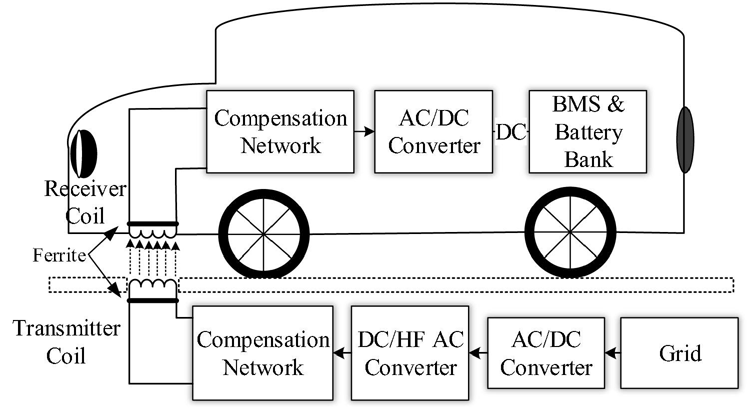

Block Diagram of Wireless EV Charging System

The basic principle of wireless charging is the same as a transformer's working principle. In wireless charging, there is a transmitter and a receiver. A 220V 50Hz AC supply is converted into high-frequency alternating current, and this high-frequency AC is supplied to the transmitter coil, which creates an alternating magnetic field that cuts the receiver coil and causes the production of AC power output in the receiver coil. But the important thing for efficient wireless charging is to maintain the resonance frequency between transmitter and receiver. To maintain the resonant frequencies, compensation networks are added at both sides. Then, finally, this AC power at the receiver side is rectified to DC and fed to the battery through the Battery Management System (BMS).

Static and Dynamic Wireless Charging

Static wireless charging occurs when vehicles remain stationary. Based on the application, Wireless charging systems for EVs can be distinguished into two categories,

- Static Wireless Charging

- Dynamic Wireless Charging

1. Static Wireless Charging

As the name indicates, the vehicle gets charged when it remains static. So here we could simply park the EV at the parking spot or in the garage, which is incorporated with WCS. The transmitter is fitted underneath the ground, and the receiver is arranged in vehicles underneath. To charge the vehicle, align the transmitter and receiver and leave it for charging. The charging time depends on the AC supply power level, the distance between the transmitter & receiver and their pad sizes.

This SWCS is best built in areas where EVs are being parked for a certain time interval.

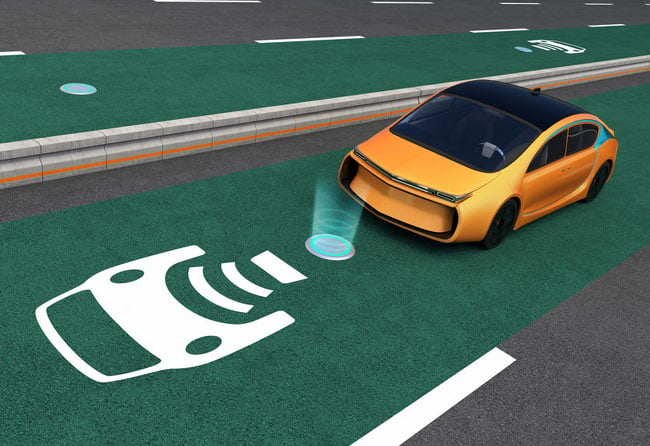

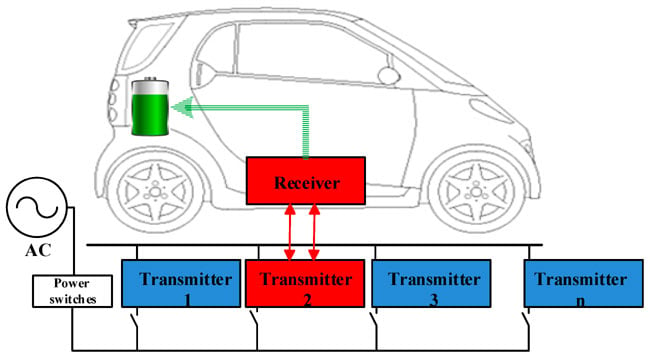

2. Dynamic Wireless Charging System (DWCS):

Dynamic wireless charging enables wireless charging of electric cars while driving. As the name indicates, here vehicles get charged while in motion. The power is transferred over the air from a stationary transmitter to the receiver coil in a moving vehicle. By using DWCS EVs, the travelling range could be improved with the continuous charging of its battery while driving on roadways and highways. It reduces the need for large energy storage, which further reduces the weight of the vehicle.

Types of Wireless EV Charging Technologies

Based on operating Techniques, EVWCS can be classified into four types

- Capacitive Wireless Charging System (CWCS)

- Permanent Magnetic Gear Wireless Charging System (PMWC)

- Inductive Wireless Charging System (IWC)

- Resonant Inductive Wireless Charging System (RIWC)

1. Capacitive Wireless Charging System (CWCS)

Wireless transfer of energy between transmitter and receiver is accomplished by means of displacement current caused by the variation of the electric field. Instead of magnets or coils as transmitter and receiver, coupling capacitors are used here for wireless transmission of power. The AC voltage is first supplied to the power factor correction circuit to improve efficiency and to maintain the voltage levels, and to reduce the losses while transmitting the power. Then it is supplied to an H-bridge for the High-frequency AC voltage generation, and this high-frequency AC is applied to the transmitting plate, which causes the development of an oscillating electric field that causes displacement current at the receiver plate by means of electrostatic induction.

The AC Voltage at the receiver side is converted to DC to feed the battery through the BMS by the rectifier and filter circuits. Frequency, voltage, size of coupling capacitors and air-gap between transmitter and receiver affect the amount of power transferred. Its operating frequency is between 100 and 600 kHz.

2. Permanent Magnet Gear Wireless Charging System (PMWC)

Here, the transmitter and receiver each consist of an armature winding and synchronised permanent magnets inside the winding. At the transmitter side, operation is similar to motor operation. When we apply the AC to the transmitter winding, it induces mechanical torque on the transmitter magnet, causing its rotation. Due to the magnetic interaction change in the transmitter, the PM field causes torque on the receiver PM, which results in its rotation in synchronous with the transmitter magnet. Now, a change in the receiver's permanent magnetic field causes the AC production in the winding, i.e, the receiver acts as a generator, as mechanical power input to the receiver PM is converted into electrical output at the receiver winding. The coupling of rotating permanent magnets is referred to as a magnetic gear. The generated AC power at the receiver side is fed to the battery after rectifying and filtering through power converters.

3. Inductive Wireless Charging System (IWC)

The basic principle of IWC is Faraday's law of induction. Here, wireless transmission of power is achieved by mutual induction of a magnetic field between the transmitter and receiver coils. When the main AC supply is applied to the transmitter coil, it creates an AC magnetic field that passes through the receiver coil, and this magnetic field moves electrons in the receiver coil, causing an AC power output. This AC output is rectified and filtered to charge the EV’s energy storage system. The amount of power transferred depends on frequency, mutual inductance and distance between transmitter and receiver coil. The operating frequency of IWC is between 19 and 50 KHz. Inductive charging EV technology utilises Faraday's law of electromagnetic induction:

4. Resonant Inductive Wireless Charging System (RIWC)

Basically, resonators having a high Quality factor transmit energy at a much higher rate, so by operating at resonance, even with weaker magnetic fields, we can transmit the same amount of power as in IWC. The power can be transferred over long distances without wires. Max transfer of power over the air happens when the transmitter and receiver coils are tuned, i.e., both coils' resonant frequencies should be matched. So to get good resonant frequencies, additional compensation networks in the series and parallel combinations are added to the transmitter and receiver coils. These additional compensation networks, along with an improvement in resonant frequency, also reduce the additional losses. The operating frequency of RIWC is between 10 and 150 kHz.

Wireless Electric Vehicle Charging Standards

Wireless charging allows EVs to charge without the need for a plug-in. If every company makes its own standards for wireless charging systems that won’t be compatible with other systems, then it won’t be a good thing. So to make wireless EV charging more user-friendly, Many international organisations like the International Electro Technical Commission (IEC), the Society of Automotive Engineers

(SAE), Underwriters Laboratories (UL) and the Institute of Electrical and Electronics Engineers (IEEE) are working on standards.

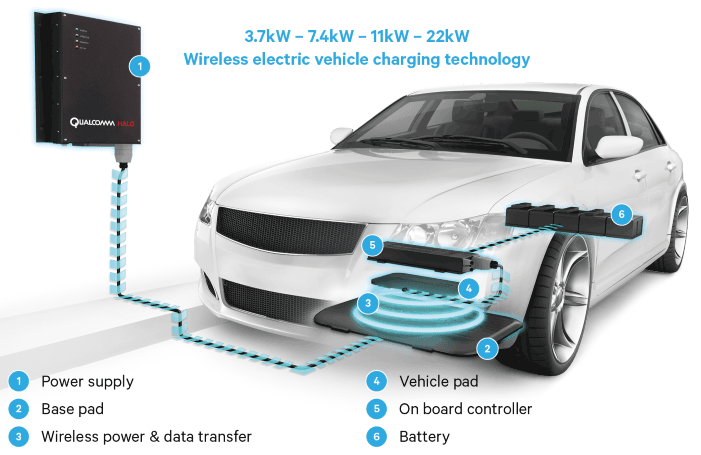

- SAE J2954 defines WPT for Light-Duty Plug-In EVs and Alignment Methodology. According to this standard, level 1 offers a maximum input power of 3.7 kW, level 2 offers 7.7Kw, level 3 offers 11 kW, and level 4 offers 22Kw. And the minimum target efficiency must be greater than 85% when aligned. Allowable ground clearance should be up to 10 inches, and side-to-side tolerance is up to 4 inches. The most preferable alignment method is magnetic triangulation, which assists in staying within charge range in manual parking and helps find parking spots for autonomous vehicles.

- SAE J1772 standard defines EV/PHEV Conductive Charge Coupler.

- SAE J2847/6 standard defines Communication Between Wireless Charged Vehicles and Wireless EV Chargers.

- SAE J1773 standard defines EV Inductively Coupled Charging.

- SAE J2836/6 standard defines Use Cases for Wireless Charging Communication for PEV.

- UL subject 2750 defines the Outline of Investigation for WEVCS.

- IEC 61980-1 Cor 1 Ed 1.0 defines EV WPT Systems General Requirements.

- IEC 62827-2 Ed 1.0 defines WPT-Management: Multiple Device Control Management.

- IEC 63028 Ed 1.0 defines WPT-Air Fuel Alliance Resonant Baseline System Specification.

Leading Companies in Wireless Charging Development

- Evatran Group is making Plugless Charging for passenger EVs like Tesla Model S, BMW i3, Nissan Leaf, and Gen 1 Chevrolet Volt.

- WiTricy Corporation is making WCS for Passenger cars and SUVs. Till now, I have been working with Honda Motor Co. Ltd, Nissan, GM, Hyundai, and Furukawa Electric.

- Qualcomm Halo is making WCS for Passenger, sports and race cars, and it has been acquired by Witricity corporation.

- Hevo Power is making a WCS for a Passenger car

- Bombardier Primove is making WCS for Passenger cars to SUVs.

- Siemens and BMW are making WCS for Passenger cars.

- Momentum Dynamic is making the WCS Corporation's Commercial fleet and Bus.

- Conductix-Wampfler is making WCS for the Industry fleet and buses.

Challenges Faced by WEVCS

- To install static and dynamic wireless charging stations on the roads, new infrastructure development is required, as current arrangements are not suitable for the installations.

- Need to maintain the EMC, EMI and frequencies as per standards for human Health and safety concerns.

Future Outlook and Market Trends

The electric vehicle wireless charging system market is growing rapidly:

∗ Government incentives for clean transportation.

∗ Integration of autonomous vehicles with automated charging.

∗ The development of smart city infrastructure is underway in many parts of the world.

∗ Possible battery technology improvements leading to greater efficiency.

Frequently Asked Questions on Wireless EV Charging System

⇥ 1. How efficient is wireless EV charging compared to plug-in charging?

New wireless charging technologies have 85-95% efficiency, marginally less than plug-in charging (95-98%), but are improving quickly with new resonant technologies and optimised coil designs.

⇥ 2. What is the highest power level for wireless EV charging?

Current SAE J2954 specifies four levels: 3.7kW, 7.7kW, 11kW, and 22kW. Lab systems have gone as high as 50kW in commercial installations.

⇥ 3. How far away does the EV have to be from the charging pad?

SAE calls for a maximum ground clearance of up to 10 inches and 4 inches side-to-side, and in conventional practice, the magnetic triangulation assists in repetitive alignment to ensure maximum performance and efficiency is attained.

⇥ 4. Is wireless charging safe around humans and animals?

Yes. Wireless charging equipment must meet stringent EMC/EMI requirements. The electric and magnetic fields are kept within the recommended exposure limits established by several international health organisations.

⇥ 5. Can wireless charging be installed in my home?

Yes, static wireless charging (aka inductive charging) systems may be installed in homes. Professional qualified installation includes a broken circuit, basic safety of connection and local building compliance.

⇥ 6. How long do wireless charging systems take to charge?

Charge times vary based on power level, battery capacity, and efficiency. Level 2 (7.7kW) systems typically charge overnight, similarly to any plug-in charger.

Discover Projects Built on Wireless Concepts

We have implemented Wireless in several exciting projects. Check out the references below to explore them further.

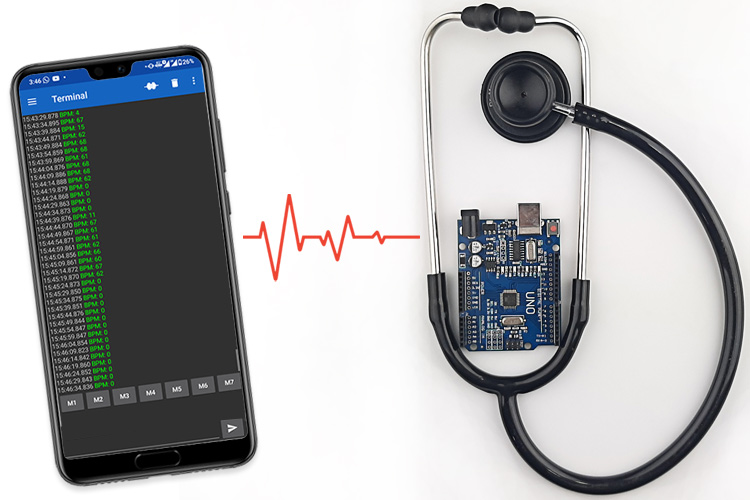

Build your own Wireless Stethoscope with Arduino and HC-05 Bluetooth

That is why in this project we thought to build an electronic stethoscope that will be able to get the heart rate of the human body and we can display the data in a Bluetooth-based serial terminal window. So without further ado, let's get started.

Wireless Stepper Motor Controller with ESP32 and TMC2240

This tutorial presents an innovative solution for ESP32 stepper motor control, WiFi functionality, allowing you to precisely adjust motor position, track performance, and receive real-time feedback from a simple web browser.

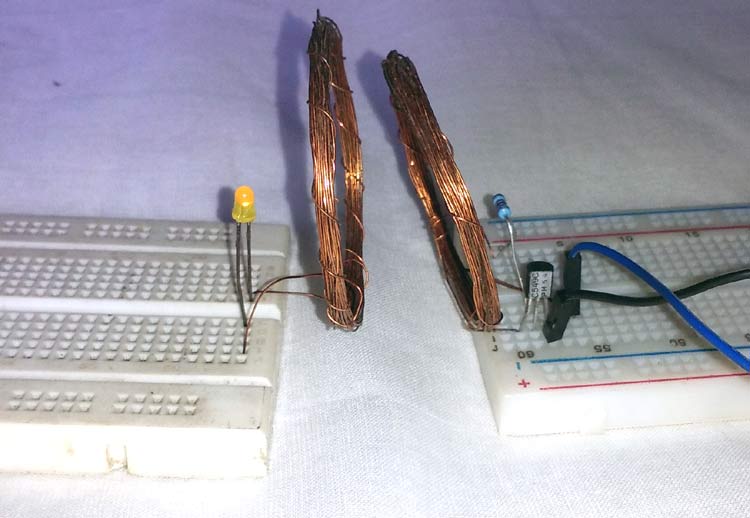

Simple Wireless Power Transmission Circuit to Glow an LED

The transmitter coil is powered by alternating current and creates a magnetic field, which is further converted into a usable voltage across the receiver coil. In this project, we will build a basic, low-power wireless transmitter circuit to glow an LED.

Useful