The power electronics industry has been on an upward spiral and shows no signs of abating, as the trend of electrification penetrates a wider range of industrial domains and entails the requirement of high-tech power electronic devices. In recent years, there has been a marked rise in the need for advanced electricity storage solutions, triggered by the essentiality of faster storage, efficient power management, and energy optimization.

Application-driven nature of the power electronics industry has played an important role in the development of electricity storage solutions, such as capacitors. Relative time-effectiveness in the charging of capacitors has been prompting their implementation in multitude of power storage devices. However, there is still potential for improvement in electricity storing capability of the capacitors, which in turn have led the development of supercapacitors - also known as ultracapacitors or electrochemical capacitors (ECs).

Focus on Efficient Power Storage Triggered the Emergence of Supercapacitors

As industrial developments started revolving around the electrification trend, innovations in the designs of supercapacitors picked up the pace. Global giants, including General Electric, conducted experiments dedicated toward design improvements in supercapacitors, in a bid to capitalize on the growing demand for supercapacitors in industries as a key electrification enabler. The NEC Corporation was among the first few companies to commercially introduce supercapacitors to the world; the Standard Oil Company of Ohio (SOHIO) is mainly attributed for the invention.

Post the emergence of superconductors as a more efficient energy storage solution, the popularity of the EC technology surged instantly. The designs of supercapacitors have advanced through several generations ever since their first commercial launch. Research organizations and leading companies in the power electronics industry are still focusing on innovating around the manufacturing methods and materials to further improve the cost-efficiency and performance of supercapacitors.

Research Institutes Discovered Innovative Manufacturing Procedures for Supercapacitors

Despite excellent operational characteristics of supercapacitors, manufacturers are still struggling to control high manufacturing costs, and lower energy storing capability of supercapacitors, as compared to batteries. Also, durability-related concerns apropos of supercapacitors has been restricting its adoption in industrial applications to a certain extent. In response to these concerns, supercapacitor manufacturing companies have been investing heavily in research and development (R&D) to design a more superior version of supercapacitors.

Some of the research-based innovations that shaped the supercapacitor market in the last five years are,

- In February 2013, researchers at University of California, Los Angeles discovered a groundbreaking and cost-effective fabrication method to manufacture micro-scale supercapacitors by using a consumer-grade LightScribe DVD burner. These micro-supercapacitors consist of a one-atom–thick layer of graphitic carbon and can be easily integrated into miniaturized electronic devices. With the use a two-dimensional sheet of graphene in combination with the new fabrication technique, researchers could reduce the manufacturing costs to a great extent and expanding the applications scope for supercapacitors.

- In July 2013, Researchers from Ulsan National Institute of Science and Technology (UNIST) developed an innovative method to mass produce 3-dimensional mesoporous graphene nano-ball (MGB) that can be used in the manufacturing of supercapacitors. The researchers projected that the properties of mesoporous graphene will improve the scalability, quality, and cost-efficiency of supercapacitors, expanding the scope of their applications in electric vehicles.

- In August 2014, engineers at Monash University in Australia developed a novel method of method of producing the graphene inside supercapacitors to improve their energy density 10 times more than commercial devices. The engineers created a macroscopic graphene material through a process similar to traditional paper manufacturing method. In addition, they further affirmed that by reducing the solution-based chemical – graphite oxide in graphene, the engineers could open new avenues for commercialization of graphene and 10x energy denser supercapacitors.

- A group of researchers in South Korea discovered an unusually innovative yet highly suitable alternative material for supercapacitor electrodes in August 2014. They devised a way to use cigarette filters in supercapacitors, which can be transformed into a high-performing carbon-based material with high power densities. Researchers could successfully use used-cigarette filters to store more electrical energy than commercially available carbon.

The Focus on Supercapacitor Material Developments Ubiquitous

The move towards the development of high-performance materials has gained utter palpability among the supercapacitor manufacturers, with the ever-growing demand for supercapacitors in various industrial applications, such as wearable consumer electronics and electric vehicles. Though graphene remains one of the apt materials for supercapacitors, ongoing research activities allude significant transformations in the supercapacitor market’s landscape.

A group of chemists from the University of Amsterdam's Van't Hoff Institute for Molecular Sciences invented a new material for supercapacitor while conducting the experiments for their fuel cells project. The researchers found that the highly-porous supercapacitor material is low-cost, light, and non-toxic, and can be used in potential commercial applications of supercapacitors, such as transportation, electronics, and energy storage devices.

Another group of scientists at UC Santa Cruz and Lawrence Livermore National Laboratory (LLNL) used ultrafast 3D-printed graphene to reduce thicknesses on the order of millimeters and improve performance characteristics of supercapacitors including power densities and capacitance retention.

A foldable supercapacitor was made out of ordinary paper by engineers from Georgia Tech and Korea University that could store more energy for longer, especially in wearable electronic products as it is flexible. Scientists, engineers, and researchers around the world are mainly focusing on balancing the power density and energy density of supercapacitors in order to avoid loss of power at once.

Recent developments and innovations in the materials used in supercapacitors manufacturing mainly center on reducing the possibility of self-discharge or short circuit. Stakeholders in the supercapacitor market are aiming to capitalize on various performance characteristics of pseudo-capacitors and hybrid capacitors, which can reflect higher energy density than any other types of supercapacitors.

While the demand for electrical double layer capacitors remain highest across the supercapacitors market, hybrid capacitors are witnessing an upsurge in demand in various industrial applications.

Automotive Industry – Key Growth Potential Area for Supercapacitor Manufacturers

Automotive sector is the high-growth potential area for manufacturers of high-quality energy storage devices, such as supercapacitors, at present. In 2013, automotive applications of supercapacitors accounted for less than 1/5th of the revenue share of supercapacitors market. However, with the recent developments in automotive industry, automobiles have become one of the most important applications of supercapacitors.

With automotive manufacturers focusing on reducing dependency on the oil industry, and governing bodies imposing strict environmental regulations, growth prospects for the electric vehicles have foreseen to be promising. This has led the supercapacitor manufacturers to eye profitable opportunities in the rapidly-evolving automotive industry.

Developing supercapacitors suitable for electric vehicles or hybrid electric vehicles is one of the most important business strategies of supercapacitor manufacturing companies. On the other hand, automotive manufacturers are also in the race to roll out most efficient electric vehicles, which justified their hunt for high-quality energy storage systems. This ultimately reflects in the ever-expanding scope for innovations in supercapacitors in the rapidly-evolving automotive industry.

In February 2019, Tesla Inc. – global giant in the automotive and energy industries – announced that it has acquired Maxwell Technologies Inc. – a leading battery technology company – for approximately US$ 218 million. The company aims to capitalize on lucrative opportunities for electric vehicles, and with this acquisition, it plans to add expertise in the field of supercapacitors that could speed up car charging capabilities.

In May 2018, Rolls-Royce – world’s leading luxury car maker – entered a collaboration agreement with Superdielectrics Ltd – a UK-based technology start-up, explore the potential of supercapacitors and create a state-of-the-art high-energy storage technology. With this partnership, Roll-Royce aims to combine its expertise in material science with Superdielectrics’ hydrophilic polymers for developing world-class supercapacitor battery applications.

Lamborghini is another leading automaker to join the pack of automobile companies that are planning to leverage supercapacitors’ extraordinary characteristics during the electrification of the automotive industry. The company’s chief technical officer recently declared that the company has previously used supercapacitors in the Lamborghini Aventador for the starter battery. Experts predicts that Aventador’s successor might use the identical supercapacitors.

The constantly evolving automotive industry has created a much exciting competitive environment for supercapacitor manufacturers. The quest for constant advancements in supercapacitors’ performance is likely to trigger some groundbreaking innovations in the supercapacitors market in coming years.

Role of Supercapacitors in Prospects of Electronics and Energy & Power Industries

Automotive and transportation industry is expected to account for more than one third of the revenue share of the supercapacitors market in the coming decade. Despite the glorified future for supercapacitors in the new-age automotive industry, consumer electronics and energy & power industries are likely to hold a lion’s share in development of the supercapacitors market.

Supercapacitors are touted as the workhorse of any electronic product that works on batteries or energy storage systems. In the coming years, supercapacitors are likely to witness ubiquitous acceptance in various industry verticals. The future of supercapacitors market is likely to witness the emergence of ECs that will power the future of modern wearables and consumer electronic products. Solar supercapacitors are also a thing from future, which is expected to have a huge sales potentials in the wearable sensors landscape, especially in wearable health devices.

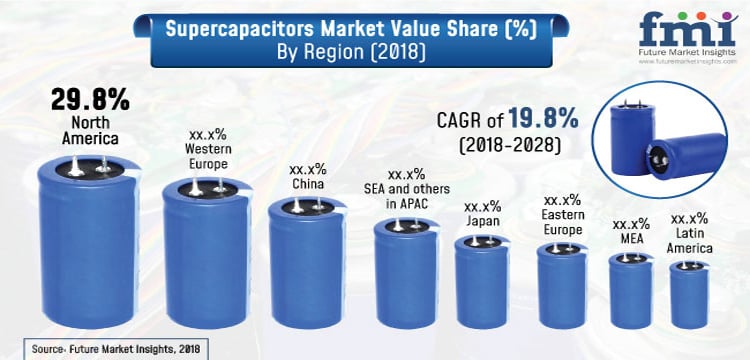

The ongoing research activities and developments in the power electronics industry continue to hint at supercapacitors replacing batteries in the near future. With increasing applications of supercapacitors in various industrial sectors, such as electronics, energy & power, military & defense, and aerospace, the global market for supercapacitors is expected to surpass US$ 5.5 billion by 2028. The exponential growth rate of the supercapacitors market is expected to amplify lucrative opportunities for researchers, manufacturers, and other stakeholders in the landscape.

Aditi Yadwadkar is an experienced market research writer and has written extensively on the Electronics and Semiconductor industry. At Future Market Insights (FMI), she works closely with the Electronics and Semiconductor research team to serve the needs of clients from across the globe. These insights are based on a report on Supercapacitors Market by FMI.