The capacitor is the most common component in electronics and is used in almost every electronics application. There are many types of capacitors available in the market for serving different purposes in any electronic circuit. They are available in many different values from 1 pico-Farad to 1 Farad capacitors and Supercapacitors. Capacitors also have different types of ratings, such as working voltage, working temperature, tolerance of the rated value and leakage current.

The leakage current of a capacitor is a crucial factor for the application, especially if used in Power electronics or Audio Electronics. Different types of capacitors provide different leakage current ratings. Apart from selecting the perfect capacitor with proper leakage, the circuit should also have the ability to control the leakage current. So first, we should have a clear understanding of capacitor leakage current. Capacitor leakage current is a critical parameter that affects the performance and longevity of electronic circuits.

Table of Contents

What is Capacitor Leakage Current?

Capacitor leakage current is a small DC current that passes through a capacitor when voltage is applied, caused by less-than-perfect insulation in the dielectric. Depending on the capacitor, voltage rating, and temperature, this leakage current can range from nanoamperes to microamperes.

Capacitor Leakage Current by Type

| Capacitor Type | Typical Leakage Current | Dielectric Material | Best Use Case |

| Ceramic Capacitor | Very Low (pA to nA) | Ceramic oxide | High-frequency, digital circuits |

| Film Capacitor | Extremely Low (pA) | Polypropylene, polyester | Audio, precision timing |

| Electrolytic Capacitor | High (µA range) | Aluminum oxide | Power supply filtering |

| Tantalum Capacitor | Medium (nA to µA) | Tantalum pentoxide | Low-voltage, space-constrained |

| Supercapacitor | Very High (mA range) | Activated carbon | Energy storage, backup power |

Understanding the Dielectric Layer and Leakage Current Relationship

The capacitor leakage current has a direct relationship with the dielectric material used in the capacitor construction. The leakage current of a capacitor has a direct relationship with the dielectric of the capacitor. Let's see the image below -

The above image is an internal construction of the aluminium electrolytic Capacitor.

Internal Components of Electrolytic Capacitors

An aluminium electrolytic capacitor leakage current originates from its internal construction, which includes several key components:

» Anode: The positive electrode where oxidation occurs

» Cathode: The negative electrode completing the circuit

» Electrolyte: Conductive medium facilitating ion movement

» Dielectric layer: Insulating oxide film preventing direct current flow

» Separator: Physical barrier between electrodes

The dielectric insulator provides insulation of the conductive plate inside the capacitor. But as there is nothing perfect in this world, the insulator is not ideal and has an insulation tolerance. Due to this, a very low amount of current will flow through the insulator. This current is called as Leakage current.

The Insulator and the flow of current can be demonstrated by using a simple capacitor and resistor. This current flow represents the capacitor leakage current and can be visualised using an equivalent circuit model. Engineers model leakage current capacitor behaviour using a parallel resistor-capacitor (RC) circuit.

This trade-off explains why electrolytic capacitor leakage current is significantly higher than film or ceramic capacitors despite their widespread use in power supply applications. The resistor has a very high value of resistance, which can be identified as an insulator resistance, and the capacitor is used to replicate the actual capacitor. Since the resistor has a very high value of resistance, the current flowing through the resistor is very low, typically in a number of nano-amperes. Insulation resistance is dependent on the type of dielectric insulator, as different type of materials changes the leakage current. The low dielectric constant provides very good insulation resistance, resulting in a very low leakage current. For example, polypropylene, plastic or Teflon-type capacitors are the examples of low dielectric constant. But for those capacitors, the capacitance is very less. Increasing the capacitance also increases the dielectric constant. Electrolytic capacitors typically have very high capacitance, and the leakage current is also high.

Knowing how to measure the leakage current of a capacitor is crucial for quality control, troubleshooting, and component selection. Several methods exist for accurate capacitor leakage current measurement, each suited for different applications and accuracy requirements.

Four Critical Factors Affecting Capacitor Leakage Current

Understanding what influences capacitor leakage current helps engineers select appropriate components and design reliable circuits.Capacitor Leakage Current generally depends on below four factors:

- Dielectric Layer

- Ambient Temperature

- Storing Temperature

- Applied Voltage

These manufacturing variables explain why capacitor leakage current measurement values can vary significantly even among identical part numbers from the same production batch.

3. Storage Conditions and Shelf Life Impact

Long-term storage without applied voltage significantly affects electrolytic capacitor leakage current. Storing a capacitor for a long time without voltage is not good for the capacitor. The storage temperature is also an important factor for leakage current. When the capacitors are stored, the oxide layer is attacked by the electrolyte material. The oxide layer starts to dissolve in the electrolyte material. The chemical process is different for different types of electrolyte material. The water-based electrolyte is not stable, whereas an inert solvent-based electrolyte contributes less leakage current due to the reduction of the oxidation layer.

However, this leakage current is temporary as the capacitor has self-healing properties when applied to a voltage. During the exposure to a voltage, the oxidation layer starts to regenerate.

The relationship between capacitor leakage current and voltage is critical for reliable operation. Each capacitor has a voltage rating. Therefore, using a capacitor above the rated voltage is a bad thing. If the voltage increases, the leakage current also increases. If the voltage across the capacitor is higher than the rated voltage, the chemical reaction inside a capacitor creates Gases and degrades the Electrolyte. Overvoltage conditions not only increase immediate capacitor leakage current but also trigger gas generation within the capacitor, potentially leading to catastrophic failure through pressure buildup and electrolyte loss.

If the capacitor is stored for a long time, such as for years, the capacitor needs to be restored to the working state by providing the rated voltage for a few minutes. During this stage, the oxidation layer is built up again and restores the capacitor to a functional stage.

Leakage Current Factors

| Factor | Impact on Leakage | Control Method |

| Dielectric Quality | Direct - Poor quality = High leakage | Source from reputable manufacturers |

| Temperature | Exponential - Doubles per 10°C | Adequate cooling and derating |

| Storage Time | Gradual increase over months/years | Reformation before use, proper storage |

| Applied Voltage | Exponential above rated voltage | Voltage derating, margin design |

How to Reduce Capacitor Leakage Current: Proven Techniques

As discussed above, a capacitor has dependencies on many factors. The first question is how the capacitor's life is calculated. The answer is to calculate the time until the electrolyte runs out. The electrolyte is consumed by the oxidation layer. Leakage current is the primary component for the measurement of how much the oxidation layer is hampered. Reducing capacitor leakage current extends component life, improves circuit performance, and enhances system reliability. Implement these strategies across the product lifecycle:

Therefore, the reduction of leakage current in the capacitor is a major key component for the life of a capacitor.

⇒ Strategy 1: Manufacturing Quality Control

The foundation for low electrolytic capacitor leakage current begins at production. Manufacturing or the production plant is the first place in a capacitor's life cycle where capacitors are carefully manufactured for low leakage current. precaution needs to be taken that the dielectric layer is not damaged or compromised.

⇒ Strategy 2: Optimal Storage Practices

Proper storage prevents capacitor leakage current degradation. The second stage is the storage. Capacitors need to be stored at the proper temperature. Improper temperature affects the capacitor electrolyte, which further downgrades the oxidation layer quality. Make sure to operate the capacitors in a proper ambient temperature, less than the maximum value.

⇒ Strategy 3: Soldering Process Control

Soldering temperature critically affects capacitor leakage current measurement results post-assembly. In the third stage, when the capacitor is soldered on the board, the soldering temperature is a key factor. Because for the electrolytic capacitors, the soldering temperature can become high enough, more than the boiling point of the capacitor. The soldering temperature affects the dielectric layers across the lead pins and weakens the oxidation layer, resulting in high leakage current. To overcome this, each capacitor comes with a data sheet where the manufacturer provides a safe soldering temperature rating and maximum exposure time. One needs to be careful about those ratings for the safe operation of the respective capacitor. This is also applicable for the Surface Mount Device (SMD) capacitors too; the peak temperature of reflow soldering or wave soldering should not exceed the maximum allowable rating. Excessive soldering heat weakens the dielectric near the terminals, permanently increasing electrolytic capacitor leakage current. Always consult the manufacturer's datasheet for specific soldering guidelines.

⇒ Strategy 4: Voltage Derating

Managing the capacitor leakage current and voltage relationship through derating: As the voltage of the capacitor is an important factor, the capacitor voltage should not exceed the rated voltage.

⇒ Strategy 5: Series Capacitor Balancing

To control leakage current capacitor diagram imbalance in series configurations. When capacitors are connected in series to achieve higher voltage ratings, unequal capacitor leakage current between units creates a voltage imbalance. Balancing the capacitor in a Series connection. The capacitor series connection is a bit complex job to balance the leakage current. This is due to the imbalance of leakage current dividing the voltage and being split between the capacitors. The split voltage can be different for each capacitor, and there is a chance that the voltage across a particular capacitor could be in excess of the rated voltage, and the capacitor starts to malfunction. This technique is essential when you need to measure capacitor leakage current accurately in series configurations.

To overcome this situation, two high-value resistors are added across the individual capacitors to reduce the leakage current.

In the image below, the balancing technique is shown where two capacitors in series are balanced using high-value resistors.

By using the balancing technique, the voltage difference influenced by leakage current can be controlled. The relationship between capacitor leakage current and voltage is nonlinear and crucial for reliable circuit design.

Frequently Asked Questions About Capacitor Leakage Current

⇥ Q1: What constitutes normal capacitor leakage current?

Normal capacitor leakage current is different by type: ceramic capacitors have picoamperes, film capacitors have 10-100 pA, electrolytic capacitors have 0.01-0.04 µA per µF×V typical, and tantalum capacitors have 0.01 µA per µF×V. Always refer to manufacturer datasheets on specific components.

⇥ Q2: How do you test for capacitor leakage current?

To test for leakage current, apply the rated voltage of the capacitor and use a digital ammeter (range set to µA) to measure the leakage current. Also, allow the capacitor to charge for 1-5 minutes, prior to taking measurements, to ensure stabilisation of the capacitor charge current measurement. The leakage current is the residual steady-state current measurement after waiting for the charge current to stabilise. Alternatively, you can measure the voltage drop across a series resistor and calculate an approximate leakage current measurement using Ohm's Law calculations (I=V/R) based on the voltage drop across the resistor.

⇥ Q3: Is leakage current a function of age for the capacitor?

Yes, as electrolytic capacitors age, the leakage current typically rises. Leakage current from electrolytic capacitors is a function of evaporating the electrolyte, leakage of the oxide layer, and can also vary under the application of voltage. For example, a stored capacitor may exhibit a transient increased leakage current until reformed when voltage is applied. Capacitors that are in operation will leak current years after usage, until finally failing with a lack of electrolyte or excessive oxide deterioration, when leakage current becomes unacceptable.

⇥ Q4: What causes high leakage current in capacitors?

Excessive capacitor leakage current is caused by a number of factors: manufacturing dielectric defects, high operating temperature (doubles every 10°C), overvoltage stress above ratings, long storage without reformation, assembly contamination, or physical stress. Soldering heat damage will irreversibly increase leakage.

⇥ Q5: Will leakage current cause damage to circuits?

High capacitor leakage current creates several issues: DC offset in audio circuits, resulting in distortion, timing error in high precision circuits, battery drain in battery-powered equipment, voltage loss in series chains of capacitors, and spurious triggering in delicate logic circuits. Measurement of capacitor leakage current on a regular basis avoids all these problems.

⇥ Q6: How does temperature affect the leakage current of capacitors?

Temperature has a very strong effect on the leakage current of capacitors, and this relationship is exponential with respect to temperature. For typical electrolytic capacitors, a leak current roughly doubles for every 10°C rise in temperature. When rated at 125°C maximum, the leakage current could be 10× that measured at 25°C. Therefore, proper thermal management and design considerations need to be made for low-leakage applications.

⇥ Q7: How do leakage current and ESR differ?

Capacitor leakage current is DC current along the dielectric insulation, expressed in nanoamperes or microamperes. ESR (Equivalent Series Resistance) is the AC resistance from the electrodes and electrolyte, expressed in milliohms. Leakage impacts DC circuits and power consumption; ESR influences ripple filtering and high-frequency performance.

Understanding and controlling capacitor leakage current is essential for designing reliable electronic circuits. Regular capacitor leakage current measurement during design validation and field maintenance ensures optimal circuit performance.

This tutorial was created by the Circuit Digest engineering team. Our experts focus on creating practical, hands-on tutorials that help makers and engineers master Raspberry Pi projects, Arduino, and IoT development projects.

I hope you liked this article and learned something new from it. If you have any doubts, you can ask in the comments below or use our forum for a detailed discussion.

Electronics Tutorials Related to Capacitors

Learn the fundamentals and practical applications of capacitors in electronic circuits. These tutorials cover capacitor types, working principles, and their roles in filtering, timing, and energy storage projects.

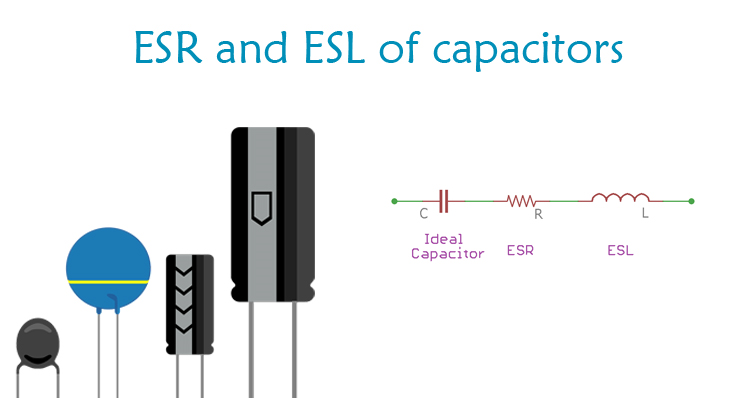

Understanding ESR and ESL in Capacitors

In this article, we will learn more about the ESR and ESL, how to measure them and how they can affect a circuit. Similar to this, an Inductor will also have some parasitic properties associated with it called DCR, which we will discuss in another article some other time.

An Introduction to Supercapacitors

Supercapacitors or Ultracapacitors are a new energy storage technology which is developed heavily in modern times. Supercapacitors provide significant industrial and economic benefits

Capacitors are filtering devices with are used abundantly in electronic circuits and applications. There are many different types of capacitors. We will discuss some of them in this article.