“When we went to the market with only a motor, the customers asked us, ‘Okay, where is the ESC?’” narrated Karna Raj, Co-Founder & Chief Technology Officer of Vector Technics. Eventually, the company added BLDC motors, propellers, Electronic Speed Controllers (ESCs), Power Distribution Boards (PDBs), and DC-DC converters to its catalog. “We just listened to the customer and kept solving the problems.” This habit of listening is what slowly assembled Vector Technics into what it is today.

We at CircuitDigest got to visit the facility of this Hyderabad-based manufacturer of electric propulsion solutions and get the inside scoop on how it all comes together.

This feature is part of our India Tech Tour series, presented in collaboration with DigiKey, a leading global distributor of electronic components serving engineers and innovators across 180+ countries with a catalog of over 17 million products from 3,000+ suppliers.

Table of Contents

Partners, Not Suppliers

The drone ecosystem in India is one that relies on external suppliers for propulsion components, and it's not hard to see why. “We do not want to place ourselves in the supplier segment. We want to be in the partner segment,” asserted Prudhvi Raj Pakalapati, Co-Founder & CEO of Vector Technics, explaining the need for indigenous components. “We want to be an active participant in their R&D process, make a world-class product, and if the customer wins, I win behind them.” He also called attention to the supply chain unreliability and security concerns that come bundled with imported parts.

On pricing, Prudhvi acknowledged that indigenous components can’t match imports yet, and that applies to other sectors in India as well. This can change with scale, but scaling presents the challenge of significant capital expenditure (CapEx). By designing manufacturing processes and equipment in-house, Vector Technics avoids expensive machinery imports, which has helped keep its prices competitive.

Machining to Balancing

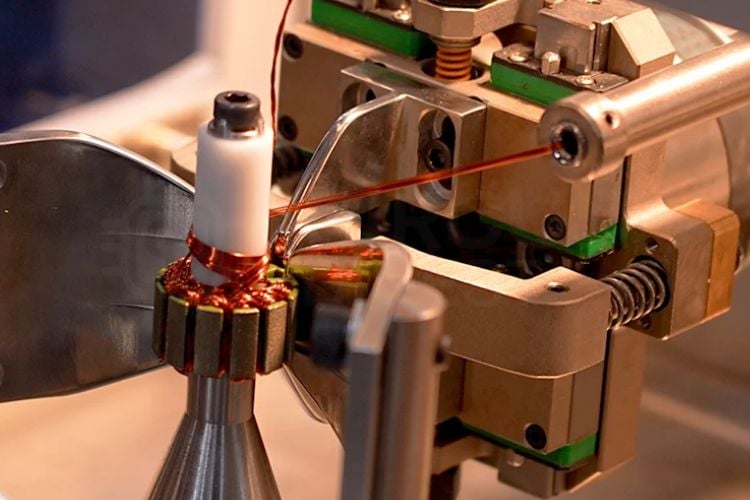

Manufacturing of a motor starts with machining metal using Computer Numerical Control (CNC) machines. These are machines that remove excess material from metals to form precise parts. While some components are outsourced, the critical ones requiring high precision are machined in-house. The company used a self-built winding machine, which was operated manually by a technician. Smaller machines were used specifically for the 3-1 and 2-8 motor series. The largest winding machine could handle stators up to 180 mm in diameter.

After winding, stators undergo back EMF testing to verify the coil integrity. The copper wire ends are then stripped to allow soldering, and a Kevlar tag is applied. Their high-voltage isolation tester can handle up to 5 kV. It is usually set at less than 500 V, which should cover ten times the operating voltage of a typical drone; however, as noted by Karna, drones today can pull up to 300-400V. A high-precision LCR meter tests the stator coils' inductance

The rotor line starts with press machines, used to press components like crowns, shafts, and bearings. The section featured both manual and automated magnet insertion machines. The balancing of rotors happens in a jig, where it rotates through a belt-driven system with a laser measuring its speed by tracking a white mark. The bed that the rotor rests on is a vibration sensor, and based on the vibration data, if imbalanced, the company identifies where to add weight to counterbalance. Epoxy putty is added carefully to balance the rotor. "Refinement of motors is refinement of imaging," is how Karna articulated the importance of this step. He pointed out how a lapse here could impact the quality of intelligence in surveillance applications like border patrolling, as vibrating propulsion motors do no favors for imaging systems. In the final assembly, the parts are inspected, checked, and cleaned manually after epoxy application.

Aerodynamics 101

In the facility, we could see propellers balanced on a knife-edge in what looked like a glass chamber. The company taught itself aerodynamics to add propellers to its stack. “Nobody taught us how to build propellers or design propellers,” recalled Karna. “So, we took it one by one, one by one. We sort of had a Vector Technics Institute of Propeller Design.”

Propellers were made using a plastic injection-moulding process with carbon-fiber-infused nylon. Carbon fiber makes up 35-40 percent of the composition, and its role extends beyond adding strength, as it also makes the propeller lighter by replacing a lot of the nylon. Manufacturing this way is easier and more cost-effective than an absolute carbon fiber approach, as that would involve having prepregs, layups, and other labour-intensive processes. While Karna acknowledged the craftsmanship involved in typical carbon fiber work, “It is a beautiful art, and it is a beautiful line of work,” he was pragmatic about their choice: “But we cannot do that. So we chose this as a path.”

Yaw Away

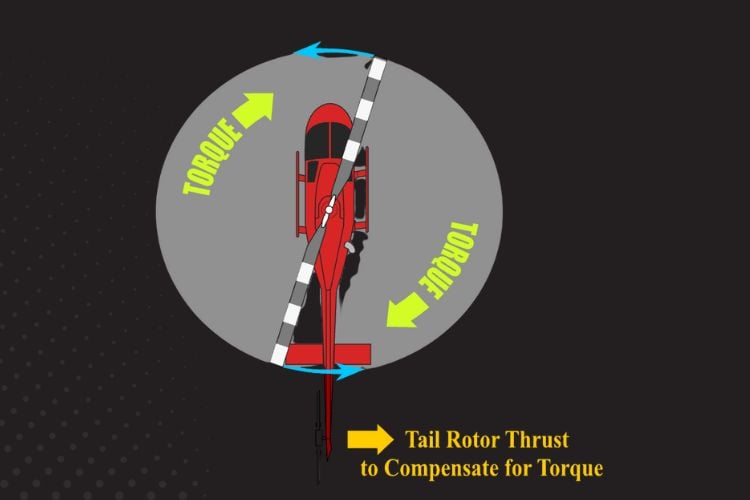

The company’s eVector motors rotate like the heading above reads... both ways. Ever used a power drill and felt it kick back when you squeeze the trigger? The bit spins one way, trying to twist the drill body and your wrist the other way. That's counter-torque, and it's why helicopters need tail rotors. Vector Technics' solution makes both the motor's constituents spin. The rotor spins a propeller in one direction, while the stator spins another in the opposite direction, cancelling the torque on the body.

Agile by Morning

As a matter of intent, Vector Technics’ manufacturing lines are not optimized for any particular way of operating. “If you notice, we do not have a single assembly line for everything. That is by design, because we do 40 to 50 models in the same facility, and demand is different at different times for different customers. So, it is very agile,” clarified Karna. “In the morning meeting, we decide that there’s a work order. And this is the glue we are going to use. This is the powder that we are going to use. This is the dye that is going to be used for punching. And everything is followed as per that paper, so that we don’t end up with a Frankenstein of a motor.” He attributed the company’s production flexibility to standardizing diameters. For the most part, customizations happen along the axis or with the winding.

The Electronics Side

The electronics manufacturing process at Vector Technics includes assembly, chemical potting, and testing. Two identical pick-and-place machines provide redundancy and help when assemblies require more component reels than a single machine can accommodate. Standard components are placed using these machines, while others are done manually. An example includes the integration of their custom-designed gold-plated lugs, as machines cannot pick those up. There is also a manual stencil printer and a reflow oven, all together supporting prototyping and small-scale production. The way Karna sees it is: “Number of prototypes is amount of turnover.” A setup like this speeds up production and, in turn, improves customer acquisition and further keeps critical intellectual property, including chips, schematics, and board designs, in-house. Highlighting why they build their own jigs and fixtures for custom tests, stressing quality, Karna said, “Let us fail here rather than a customer blowing up something.”

Pointing out occasional counterfeit chips, he explained that there was a dedicated team that handled keeping the supply chain clean. The people involved in schematic engineering and PCB design work in tandem with the mechanical team. “Managing thermals is the name of the game here,” said Karna, underlining its significance. “A cool ESC is a more efficient ESC.” The company has both a power board and a microcontroller board concept, allowing for bulk production while retaining some flexibility to customize.

Purposefully Redundant

From past experiences, Vector Technics has learnt not to rely on any single chip or brand for its products. Doing this has caused unwarranted hold-ups and even forced the company to pause a product launch once due to a raw material being unavailable. Redundant supply chains were their response, as this lets them adjust designs without disrupting a product line. Even the firmware team maintains the same firmware IP across microcontrollers from STMicroelectronics, Silicon Labs, TI, and Infineon to steer clear of lock-ins.

Scaling With Zen

Ninety-four is the number of SKUs Vector Technics packs in its catalog at the moment (during the tech tour). The company aims to add somewhere between three and nine SKUs per month. This is not a mindless scaling process, though, as they also retire underperforming ones. Prudhvi expects their “wannabe catalog” to feature a hundred and fifty SKUs next financial year.

“Previously, we were able to manufacture with two shifts, full workforce, full enthusiasm, about 300 motors in a month. We can do that in a shift right now. So, my per-month capacity, if we actually calculated it, technically, running 24/7, we can closely manufacture about 15,000 motors alone per month,” elaborated Prudhvi, describing the manufacturing capacity before and after being acquired by Zen Technologies. “Electronics, we can manufacture much more. It is close to around 20,000 electronic power distribution boards or ESCs, or DC-DC converters. But currently, we are running only one shift because we do not have that level of traction. But the facility infrastructure, supply chain, teams, everything is planned and scheduled in a way that we might go 24/7 when we have the demand.”

Prudhvi also went into great detail about how the Zen Technologies acquisition has proved beyond fruitful, calling the company’s founders less of investors and more of mentors. “So, when we talk to both the founders in Zen Technologies, they give a lot of insight of what you need to focus on, and always quality comes first. And you have to make stuff for India, put our products in a global scale, where everybody appreciates India. So, they drive that super hard,” he said. “And on every catch-up call that we usually have, they only are driven by one thing: what did we make better? How is the company driving its R&D? It’s never about, hey, what are we doing with this marketing? Hey, what’s the revenue numbers? Nothing. It’s what are you manufacturing, and how much R&D did the company provide as an output.”

Defense, Not Agriculture

On the sales front, India dominated with 97% of the company’s revenue last year. While they are seeing better international reception this year, India still dominates, accounting for 90% of sales. Just last quarter, Vector Technics entered the robotic drives segment, but most of its revenue still comes from drone companies. Within this segment, the focus remains largely on commercial, defense, and professional drones, rather than agricultural drones. Here’s Prudvi’s reasoning behind the deprioritization of agricultural drones: “We want to cater to nation-first sort of companies. And also, they are very open to tech changes. So, the people who are building drones in a commercial scale, they’ll understand what is the difference between each gram. And I can talk very closely with them, get feedback very fast, and correct it very fast. I did not see that feedback coming in from agri-drone manufacturers. So, because we want to make the product perfect, we’re focusing only into this segment first.”

According to Prudhvi, when pitching to defense clients, everything revolves around quality. While noting how most of Vector Technics’ products are MIL-STD-810G pre-qualified or certified, he chalked certifications up to an insignificant hurdle. The real questions are: how many hours can it fly? What guarantees can be provided? Can it operate for 3,000 hours? Quality takes precedence over everything else.

Finding True Partners

One of the first hurdles Vector Technics faced was finding the right suppliers, be it mechanical or electronics. It took the company some time to navigate and understand the importance of having a supply chain comprised of genuine suppliers. Prudhvi stated that this is something that’s just learnt through experience. He also stressed how vital vendor relationships are and that these relationships are built on trust. “Don't tell them, ‘Hey, give me a quotation for one lakh units,’ and then give a purchase order for ten units. That's not appreciated anywhere.”

While acknowledging a lack of understanding of what happens abroad, Prudhvi highlighted that a database to refer to and find vendors to partner with is absent in India. He believes this to be the reason why it’d take him five years to start Vector Technics if he had to do it all again. He noted that there are hardware-focused groups on WhatsApp that can help, but it takes time to find the right one.

Working With the System

Prudhvi is against dwelling on regulations or expecting a “single-window” solution for everything. In his view, the direction should be to understand and navigate the existing ecosystem. “I think we have good ecosystem, both at central level as well as state level; there are no issues from the government. And of course, you will need to know the processes for you to get through some loops and hoops. But that is learning,” he observed. “Most of the people might not like it. But I think our government is very supportive. I think they are supporting not just ease of doing business, but the way they promote drones, the way they promote deep tech, the way they are giving challenges like iDEX challenge and a lot of challenges online. "

Best Propulsion Company, Next

While located distant from the city, Vector Technics has been able to attract talent by presenting a compelling story. According to Prudhvi, the company has been able to keep its attrition rate close to zero by delivering on that story. This is a story where each team operates like a mini-startup within the company. Karna: "We don't try to put anyone into a can and ask them to contort to our shape. We let them be, and we, in fact, harvest their ideas and systems."

“We want to be the best propulsion company for drones to start with,” expressed Prudhvi. “And we want to achieve that within next year and have a wide range of portfolio, so that people don't need to call or don't need to find an external factory or a company that they need to depend upon. They just need to come to Vector Technics and find the right propulsion solution for them.” The company also has its eyes set on robotics with plans of launching robotic servos, drives, and software as a package next year.