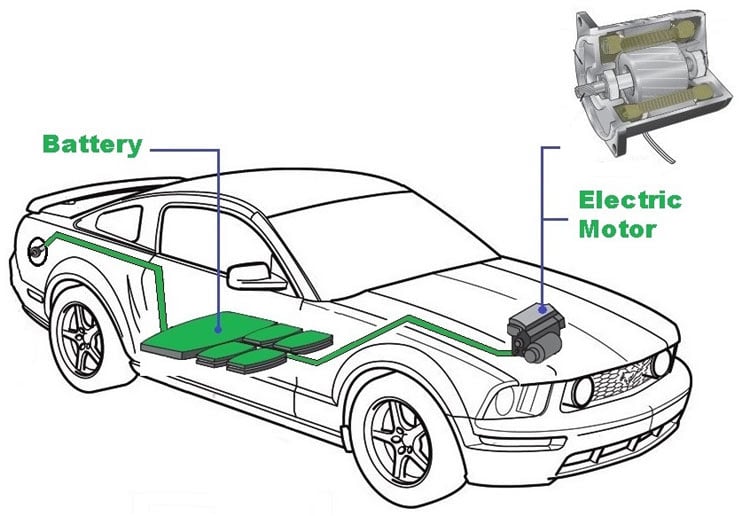

Electric vehicles are not something new to this world, but with the technological advancement and increased concern on controlling pollution has given it a tag of future mobility. The core element of the EV, apart from Electric Vehicle Batteries, which replaces the Internal Combustion engines is an Electric motor. The rapid development in the field of Power electronics and control techniques has created a space for various types of electric motors to be used in Electric Vehicles. The electric motors used for automotive applications should have characteristics like high starting torque, high power density, good efficiency, etc.

Various types of Electric Motors used in Electric Vehicles

- DC Series Motor

- Brushless DC Motor

- Permanent Magnet Synchronous Motor (PMSM)

- Three Phase AC Induction Motors

- Switched Reluctance Motors (SRM)

1. DC Series Motor

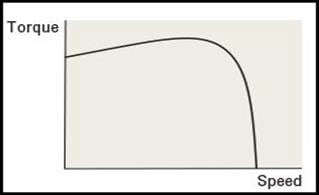

High starting torque capability of the DC Series motor makes it a suitable option for traction application. It was the most widely used motor for traction application in the early 1900s. The advantages of this motor are easy speed control and it can also withstand a sudden increase in load. All these characteristics make it an ideal traction motor. The main drawback of DC series motor is high maintenance due to brushes and commutators. These motors are used in Indian railways. This motor comes under the category of DC brushed motors.

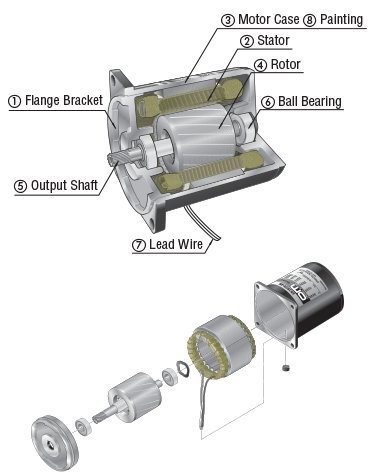

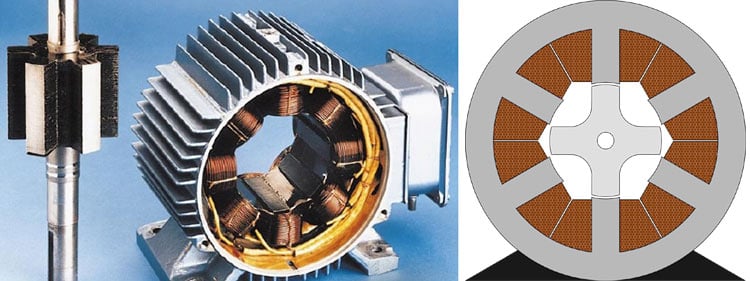

2. Brushless DC Motors

It is similar to DC motors with Permanent Magnets. It is called brushless because it does not have the commutator and brush arrangement. The commutation is done electronically in this motor because of this BLDC motors are maintenance free. BLDC motors have traction characteristics like high starting torque, high efficiency around 95-98%, etc. BLDC motors are suitable for high power density design approach. The BLDC motors are the most preferred motors for the electric vehicle application due to its traction characteristics. You can learn more about BLDC motors by comparing it with normal brushed motor.

BLDC motors further have two types:

i. Out-runner type BLDC Motor:

In this type, the rotor of the motor is present outside and the stator is present inside. It is also called as Hub motors because the wheel is directly connected to the exterior rotor. This type of motors does not require external gear system. In a few cases, the motor itself has inbuilt planetary gears. This motor makes the overall vehicle less bulky as it does not require any gear system. It also eliminates the space required for mounting the motor. There is a restriction on the motor dimensions which limits the power output in the in-runner configuration. This motor is widely preferred by electric cycle manufacturers like Hullikal, Tronx, Spero, light speed bicycles, etc. It is also used by two-wheeler manufacturers like 22 Motors, NDS Eco Motors, etc.

ii. In-runner type BLDC Motor:

In this type, the rotor of the motor is present inside and the stator is outside like conventional motors. These motor require an external transmission system to transfer the power to the wheels, because of this the out-runner configuration is little bulky when compared to the in-runner configuration. Many three- wheeler manufacturers like Goenka Electric Motors, Speego Vehicles, Kinetic Green, Volta Automotive use BLDC motors. Low and medium performance scooter manufacturers also use BLDC motors for propulsion.

It is due to these reasons it is widely preferred motor for electric vehicle application. The main drawback is the high cost due to permanent magnets. Overloading the motor beyond a certain limit reduces the life of permanent magnets due to thermal conditions.

3. Permanent Magnet Synchronous Motor (PMSM)

This motor is also similar to BLDC motor which has permanent magnets on the rotor. Similar to BLDC motors these motors also have traction characteristics like high power density and high efficiency. The difference is that PMSM has sinusoidal back EMF whereas BLDC has trapezoidal back EMF. Permanent Magnet Synchronous motors are available for higher power ratings. PMSM is the best choice for high performance applications like cars, buses. Despite the high cost, PMSM is providing stiff competition to induction motors due to increased efficiency than the latter. PMSM is also costlier than BLDC motors. Most of the automotive manufacturers use PMSM motors for their hybrid and electric vehicles. For example, Toyota Prius, Chevrolet Bolt EV, Ford Focus Electric, zero motorcycles S/SR, Nissan Leaf, Hinda Accord, BMW i3, etc use PMSM motor for propulsion.

4. Three Phase AC Induction Motors

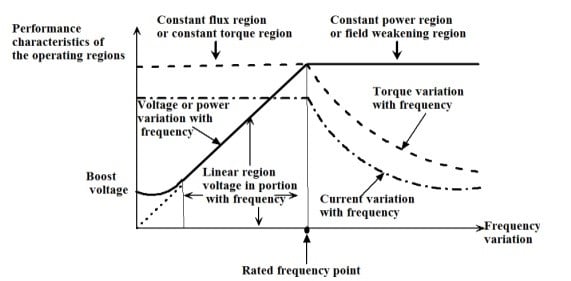

The induction motors do not have a high starting toque like DC series motors under fixed voltage and fixed frequency operation. But this characteristic can be altered by using various control techniques like FOC or v/f methods. By using these control methods, the maximum torque is made available at the starting of the motor which is suitable for traction application. Squirrel cage induction motors have a long life due to less maintenance. Induction motors can be designed up to an efficiency of 92-95%. The drawback of an induction motor is that it requires complex inverter circuit and control of the motor is difficult.

In permanent magnet motors, the magnets contribute to the flux density B. Therefore, adjusting the value of B in induction motors is easy when compared to permanent magnet motors. It is because in Induction motors the value of B can be adjusted by varying the voltage and frequency (V/f) based on torque requirements. This helps in reducing the losses which in turn improves the efficiency.

Tesla Model S is the best example to prove the high performance capability of induction motors compared to its counterparts. By opting for induction motors, Tesla might have wanted to eliminate the dependency on permanent magnets. Even Mahindra Reva e2o uses a three phase induction motor for its propulsion. Major automotive manufacturers like TATA motors have planned to use Induction motors in their cars and buses. The two-wheeler manufacturer TVS motors will be launching an electric scooter which uses induction motor for its propulsion. Induction motors are the preferred choice for performance oriented electric vehicles due to its cheap cost. The other advantage is that it can withstand rugged environmental conditions. Due to these advantages, the Indian railways has started replacing its DC motors with AC induction motors.

5. Switched Reluctance Motors (SRM)

Insights for Selecting the Right Motor for your EV

For selecting the appropriate electric vehicle motors, one has to first list down the requirements of the performance that the vehicle has to meet, the operating conditions and the cost associated with it. For example, go-kart vehicle and two-wheeler applications which requires less performance (mostly less than 3 kW) at a low cost, it is good to go with BLDC Hub motors. For three-wheelers and two-wheelers, it is also good to choose BLDC motors with or without an external gear system. For high power applications like performance two-wheelers, cars, buses, trucks the ideal motor choice would be PMSM or Induction motors. Once the synchronous reluctance motor and switched reluctance motor are made cost effective as PMSM or Induction motors, then one can have more options of motor types for electric vehicle application.

This was actually infomative

This was very informative ..thanks for the information..

Can I put 4 hub motors on my full size pickup and is there a kit .what is the speed and price please

Can I use a old truck starter motor with permanent magnet fields?

You wrote "induction motors are the preferred choice for performance oriented electric vehicles due to its cheap cost."

Yet, as the article mentions, a lot of auto makers use another type of motor mentioned before inductor motor.

Inductor is cheap, low maintenance. Why so many manufacturers won't pick it?

Is there a high license fee or something else?

It is informative... Thanks.