In the previous tutorial, we saw how a Dual Power Supply Circuit is designed. Now, we learn about Dual Converters, which can convert AC to DC and DC to AC at the same time. As the name suggests, Dual Converter has two converters, one converter works as a rectifier (Converts AC to DC) and the other converter works as an inverter (converts DC into AC). Both converters are connected back-to-back with a common load as shown in the above picture. To learn more about Rectifier and Inverter, follow the links.

Why do we use the dual converter? If only one converter can supply the load, then why do we use two converters? These questions may arise, and you will get the answer in this article.

Table of Contents

What is a Dual Converter in Power Electronics?

In a dual converter in power electronics, two converters are connected in a back-to-back configuration under a common loading condition. The first converter operates as a rectifier (converting an AC to DC), while the second converter operates as an inverter (converting a DC to AC). This unique configuration enables bidirectional power flow, allowing dual converters to be suitable for any high-power applications that require motor reversal and regenerative braking capabilities.

Dual Converter Operating Modes: Comparison Table

| Feature | Without Circulating Current | With Circulating Current |

|---|---|---|

| Operation | Only one converter conducts at a time | Both converters conduct simultaneously |

| Reactor Required | No | Yes (current-limiting reactor) |

| Delay Time | 10-20 milliseconds required | No delay time needed |

| Control System | Sophisticated control required | Simpler control system |

| Response Time | Slower (due to delay) | Very fast response |

| Load Current | May be discontinuous | Continuous and smooth |

| Cost | Lower (no reactor cost) | Higher (reactor + higher rated thyristors) |

| Efficiency | Higher efficiency | Lower (due to circulating current losses) |

| Power Factor | Better power factor | Lower power factor |

| Best Application | Cost-sensitive applications | High-performance DC drives |

Why Use Dual Converters?

It is possible to operate with one converter supplying power to the load, but when the following conditions apply, dual converter operation is required:

- Bidirectional power flow is required- Energy flows from source to load and load to source.

- Four-quadrant operation is necessary - Current and voltage both must be reversible.

- Regenerative braking is needed- Recovering energy as the motor decelerates

- Accurate speed control is required- Requires variable speed DC drives in industrial applications

- Motor reversal without mechanical switches- Without mechanical means of switching the rotation of the motor.

Here we have two converters connected back-to-back. Due to this type of connection, this device can be designed for four-quadrant operation. It means that both the load voltage and load current become reversible. How is four-quadrant operation possible in the dual converter? That we will see further in this article.

Generally, dual converters are used for the reversible DC drives or variable speed DC drives. It is used for high-power applications.

Four Quadrant Operation in a Dual Converter

A dual converter's key defining property is its ability to operate in all four quadrants of the voltage-current plane. This capability to operate in four quadrants of features, both forward/reverse motion and motoring/braking modes, to achieve complete motor control. Understanding quadrant operation is essential to understanding dual converter working principles.

The dual converter diagram demonstrates four-quadrant capability, where each quadrant represents a specific combination of voltage and current polarity:

First quadrant: voltage and current both positive.

Second quadrant: voltage is positive and current is negative.

Third quadrant: voltage and current both negative.

Fourth quadrant: voltage is negative and current is positive.

| Quadrant | Voltage | Current | Operation Mode | Power Flow |

|---|---|---|---|---|

| First (I) | Positive (+) | Positive (+) | Forward Motoring | Source → Load |

| Second (II) | Positive (+) | Negative (−) | Reverse Regenerative Braking | Load → Source |

| Third (III) | Negative (−) | Negative (−) | Reverse Motoring | Source → Load |

| Fourth (IV) | Negative (−) | Positive (+) | Forward Regenerative Braking | Load → Source |

Out of these two converters, the first converter works in two quadrants depending on the value of the firing angle α. This converter works as a rectifier when the value of α is less than 90˚. In this operation, the converter produces a positive average load voltage and load current, and operates in the first quadrant.

When the value of α is greater than 90˚, this converter works as an inverter. In this operation, the converter produces a negative average output voltage and the direction of current is not changed. That’s why the load current remains positive. In the first quadrant operation, the energy transfers from the source to the load and in the fourth quadrant operation, the energy transfers from the load to the source.

Similarly, the second converter operates as a rectifier when the firing angle α is less than 90˚, and it operates as an inverter when the firing angle α is greater than 90˚. When this converter operates as a rectifier, the average output voltage and current are both negative. So, it operates in the third quadrant, and power flow is from load to source. Here, the motor rotates in the reverse direction. When this converter operates as an inverter, the average output voltage is positive and the current is negative. So, it operates in the second quadrant, and the power flow is from load to source.

When power flows from load to source, the motor behaves like a generator, and this makes regenerative braking possible.

Dual Converter Working Principle (Ideal Dual Converter)

To understand the dual converter working, we assume that both converters are ideal. It means that they produce pure DC output voltage; there is no ripple at the output terminals. The simplified equivalent diagram of the dual converter is shown in the figure below.

In the above circuit diagram, the converter is assumed to be a controllable DC voltage source, and it is connected in series with the diode. The firing angle of the converters is regulated by a control circuit. So, the DC voltages of both converters are equal in magnitude and opposite in polarity. This makes it possible to drive current in the reverse direction through the load.

The converter operating as a rectifier is called a positive group converter, and the other converter working as an inverter is called a negative group converter.

The average output voltage is a function of the firing angle. For single-phase inverter and three-phase inverter, the average output voltage is in the form of equations below.

EDC1 = EmaxCos⍺1 EDC2 = EmaxCos⍺2

Where α1 and α2 are the firing angles of converter-1 and converter-2, respectively.

For a single-phase dual converter,

Emax = 2Em /π

For a three-phase dual converter,

Emax = 3√3Em /π

For an ideal converter,

EDC = EDC1 = -EDC2 EmaxCos⍺1 = -EmaxCos⍺2 Cos⍺1 = -Cos⍺2 Cos⍺1 = Cos (180⁰ - ⍺2) ⍺1 = 180⁰ - ⍺2 ⍺1 + ⍺2= 180⁰

As discussed above, the average output voltage is a function of the firing angle. It means that for the desired output voltage, we need to control the firing angle. A firing angle control circuit can be used such that, when the control signal Ec changes, firing angles α1 and α2 will change in such a way that they will satisfy the following graph.

Practical Dual Converter

Practically, we cannot assume both converters as ideal converters. If the firing angle of converters is set in such a way that ⍺1 + ⍺2= 180⁰. In this condition, the average output voltage of both converters is the same in magnitude but opposite in polarity. But due to ripple voltage, we cannot exactly get the same voltage. So, there is an instantaneous voltage difference at the DC terminals of the two converters, which produces an enormous circulating current between the converters, and that will flow through the load.

Therefore, in the practical dual converter, it is necessary to control the circulating current. There are two Modes to control the circulating current.

1) Operation without a circulating current

2) Operation with circulating current

1) Dual Converter Operation without Circulating Current

In this type of dual converter, only one converter is in conduction, and the other converter is temporarily blocked. So, at a time one converter operates, and the reactor is not required between the converters. At a particular instant, let's say converter-1 acts as a rectifier and supplies the load current. At this instant, converter-2 is blocked by removing the firing angle. For the inversion operation, converter-1 is blocked and converter-2 is supplying the load current.

The pulses to the converter-2 are applied after a delay time. The delay time is around 10 to 20 milliseconds. Why do we apply a delay time between the change of operation? It ensures the reliable operation of thyristors. If converter-2 triggers before the converter-1 has completely turned off, a large amount of circulating current will flow between converters.

There are many control schemes to generate a firing angle for the circulating current free operation of the dual converter. These control schemes are designed to operate very sophisticated control systems. Here, at a time, only one converter is in conduction. Therefore, it is possible to use only one firing angle unit. A few basic schemes are listed below.

A) Converter selection by control signal polarity

B) Converter selection by load current polarity

C) Converter selection by both control voltage and load current

2) Dual Converter Operation with Circulating Current

Without a circulating current converter, it requires a very sophisticated control system, and the load current is not continuous. To overcome these difficulties, there is a dual converter which can operate with the circulating current. A current-limiting reactor is connected between the DC terminals of both converters. The firing angle of both converters is set in such a way that the minimum amount of circulating current flows through the reactor. As discussed in the ideal inverter, the circulating current is zero if ⍺1 + ⍺2= 180⁰.

Let's say the firing angle of converter-1 is 60˚, then the firing angle of converter-2 must be maintained at 120˚. In this operation, converter-1 will operate as a rectifier and converter-2 will operate as an inverter. Thus, in this type of operation, at a time, both converters are in conducting state. If the load current is reversed, the converter, which is operated as a rectifier, is now operating as an inverter, while the converter, which is operated as an inverter, is now operating as a rectifier. In this scheme, both converters operate at the same time. So, it requires two firing angle generator units.

The advantage of this scheme is that we can get a smooth operation of the converter at the time of inversion. The time response of the scheme is very fast. The normal delay period is 10 to 20 milliseconds, but in the case of circulating current, free operation is eliminated.

The disadvantage of this scheme is that the size and cost of the reactor are high. Because of the circulating current, the power factor and efficiency are low. To handle the circulating current, the thyristors with high current ratings are required.

According to the type of load, single-phase and three-phase dual converters are used.

1) Single-Phase Dual Converter Circuit Diagram

The circuit diagram of the dual converter is shown in the figure below. A separately excited DC motor is used as a load. The DC terminals of both the converters are connected to the terminals of the armature winding. Here, two single-phase full converters are connected back-to-back. Both converters supply a common load.

The firing angle of converter-1 is α1, and α1 is less than 90˚. Hence, the converter-1 acts as a rectifier. For a positive half cycle (0 < t < π), thyristor S1 and S2 will conduct, and for a negative half cycle (π < t < 2π), thyristor S3 and S4 will conduct. In this operation, both the output voltage and current are positive. So, this operation is known as a forward motoring operation, and the converter works in the first quadrant.

The firing angle of converter-2 is 180 - α1 = α2, and α2 is greater than 90˚. So, converter-2 acts as an inverter. In this operation, the load current remains in the same direction. The polarity of the output voltage is negative. Therefore, the converter works in the fourth quadrant. This operation is known as regenerative braking.

For reverse rotation of the DC motor, converter-2 acts as a rectifier and converter-1 acts as an inverter. The firing angle of converter-2 α2 is less than 90˚. The alternative voltage source supplies the load. In this operation, the load current is negative, and the output average voltage is also negative. Therefore, the converter-2 works in the third quadrant. This operation is known as reverse motoring.

In reverse operation, the firing angle of converter-1 is less than 90˚, and the firing angle of converter-2 is greater than 90˚. So, in this operation, the load current is negative, but the average output voltage is positive. So, the converter-2 works in the second quadrant. This operation is known as reverse regenerative braking.

Single-Phase Dual Converter Waveform

The single-phase dual converter waveform is shown in the figure below.

2) Three-Phase Dual Converter

The circuit diagram of the three-phase dual converter is shown in the figure below. Here, two three-phase converters are connected back-to-back. The principle of operation is the same as a single-phase dual converter.

So this is how Dual Converters are designed, and as already told, they are generally used to build reversible DC drives or variable speed DC drives in high-power applications.

Advantages of Three-Phase Dual Converters

» Increased power capacity: Appropriate for industrial motors (100 kW to several MW)

»Lower outputs ripple: Smoother DC voltage with six-pulse operation

»Better power factor: Better than a single-phase converter

»Lower harmonics: Less harmonic substance on both AC and DC sides

»More efficient: Higher overall efficiencies for higher power ratings.

Dual Converter Applications in Industry

| Industry | Application | Power Range |

|---|---|---|

| Steel & Metal | Rolling mills, reversing mills | 500 kW - 5 MW |

| Mining | Winders, conveyors, crushers | 200 kW - 2 MW |

| Paper & Pulp | Paper machines, winders | 100 kW - 1 MW |

| Transportation | Electric locomotives, metros | 1 MW - 10 MW |

| Marine | Ship propulsion systems | 500 kW - 20 MW |

Troubleshooting Common Dual Converter Issues

| Problem | Possible Cause | Solution |

|---|---|---|

| Excessive circulating current | Firing angle mismatch | Recalibrate firing circuits to maintain α₁ + α₂ = 180° |

| Irregular motor operation | Insufficient delay time | Increase delay to 15-20 ms in circulating current-free mode |

| Poor regeneration | Incorrect inverter firing angle | Ensure α > 90° for inverter operation |

| Thyristor failure | Overcurrent during switching | Add or increase reactor inductance |

| Excessive harmonics | Poor AC filter design | Install or upgrade AC line filters |

Conclusion

Dual converters represent a sophisticated solution for applications requiring bidirectional power flow and four-quadrant operation. Whether implementing a single-phase dual converter for moderate power applications or a three-phase dual converter for heavy industrial use, understanding the dual converter working principle, circuit diagrams, and operational modes is essential for optimal system design.

Frequently Asked Questions About Dual Converters

⇥ 1. What are the reasons for having a dual converter in DC drives?

Dual converters are able to perform the four modes of operation, two being forward rotation and reverse motor rotation with regenerative braking capabilities. Bidirectional power flow makes them suitable for variable speed DC drives as well as for use in hoisting applications, rolling mills or in other industrial applications requiring reverse operation and precise speed control (high slip areas).

⇥ 2. How do the firing angles relate in a dual converter?

The firing angles of both converters, based on ideal dual converter operation, maintain the relationship α₁ + α₂ = 180 °. In converter-1, firing angle α₁ is less than 90 ° when it is operating as a rectifier; if greater than 90 °, it is operating as an inverter. Converter-2 is exercising a complementary operation.

⇥ 3. What is the circulating current in a dual converter?

Circulating current is the current that flows between two converters because of instantaneous voltage differences at the DC terminals resulting from ripple voltage. In a practical dual converter, a current-limiting reactor is connected between converters to keep this circulating current at an acceptable level.

⇥ 4. What is the four-quadrant operation in a dual converter?

Four-quadrant operation provides the capability for both voltage and current to reverse: Q1 (forward motoring), Q2 (reverse regenerative braking), Q3 (reverse motoring), and Q4 (forward regenerative braking). Four-quadrant operation provides the opportunity for bi-directional power flow in complete motor control, including accelerating, decelerating, and recovering energy.

⇥ 5. What are the uses of a dual converter?

Typical uses are in renewable DC motor drives, variable speed industrial drives, rolling mills, hoists, electric traction devices, elevators, cranes, and high-power machine tools. Any application requiring bi-directional power transfer and four-quadrant operation would specifically benefit from a dual converter.

⇥ 6. What are the benefits of a dual converter with circulating current?

Benefits of a dual converter with circulating current include a more stable converter operation when inversion occurs, the option of operating as a synchronous converter in dual-converter operation, and an exceptionally quick response time, defined as a round-trip delay of approximately 0-15 ms, while the load retains the current load (steady-state) and with simple control systems. However, drawbacks of the dual converter with circulating current include larger reactors, a drop-off in efficiency and power factor (overall), and higher rated thyristors to permit circulation current to flow through them.

⇥ 7. How does regeneration braking occur with a dual converter?

With regeneration braking, the motor is acting, in effect, as a "machine" (or generator) while currents are taken from the load to the supply. For example, during forward braking (Q4), the first converter is α1 > 90° in terms of its inversion degree, and during reverse braking (Q2), the second converter is α2 > 90° in oscillation. This means that the kinetic energy is being "returned" from the load back to the supply during the regenerative braking, and this contributes to the overall efficiency of the system.

Electronics Projects Featuring Converters

We’ve applied converters in multiple innovative projects; see the resources below for more insights.

In this article, we will be learning about the features and working of the XL4015, which is a 5A 180KHz 36V Buck DC to DC Converter. Here we will desolder all the components from the module, completely reverse engineer the schematic and make the PCB from it, so that we can order the components and make the PCB ourselves.

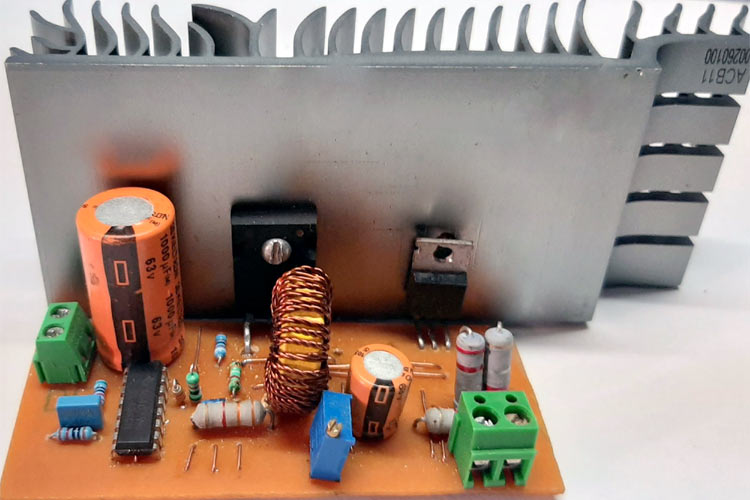

High Power High Efficiency Buck Converter Circuit using TL494

So, in this article, we are going to design, calculate and test a high-efficiency buck converter circuit based on the popular TL494 IC, and at last, there will be a detailed video showing the working & testing part of the circuit.

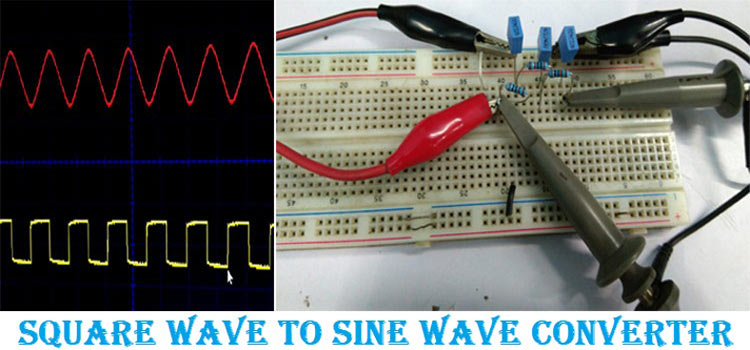

Simple Square wave to Sine Wave Converter

In this project, we will discuss how a square wave to sine wave converter circuit works and how it can be built using simple passive electronics. You can also check out other waveform generator circuits listed below.