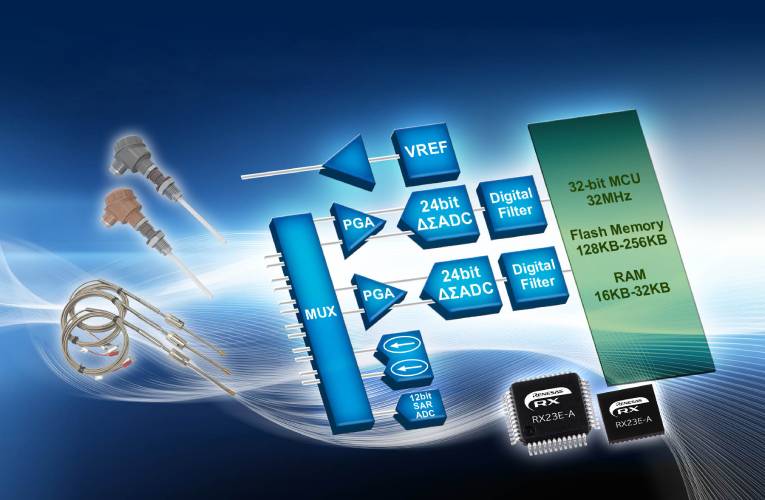

Renesas Electronics Corporation released the RX23E-A Group 32-bit RX microcontrollers (MCUs) For High-Precision Sensing and Measurement Equipment deliver better-than 0.1% Precision Performance in Temperature, Pressure, Weight, Flow and other measurements. The RX23E-A Group 32-bit RX MCUs achieve AFE precision at the highest class in the industry (offset drift: 10 nV/°C, gain drift: 1 ppm/°C, and RMS noise: 30 nV rms) without the need of combining dedicated A/D converter circuits with high-precision operational amplifier ICs.

The high-precision AFE IP (intellectual property) integration on a single chip using the same fabrication process technology, Renesas has made it possible to implement high-precision sensor measurement, computation, control, and communications on a single chip. This enables the system manufactures to reduce the number of required components, save space, and simplify system design in a wide range of equipment requiring high-precision measurement, such as sensing, temperature controllers, recording, weighing, and force sensing along with accelerating endpoint intelligence by enabling distributed processing with MCUs.

The Renesas has developed a high-precision AFE and integrated it into an RX MCU for fulfilling the stability when measuring small signals at high precision over a wide environmental temperature range reducing noise characteristics and temperature drift characteristics to low levels. The RX23E-A MCUs are based on the RXv2 core, which features operating speeds of 32 MHz, a digital signal processor (DSP), and superlative floating point unit (FPU) calculations. This enables the implementation of adaptive control using temperature data and inverse matrix calculations using 6-axis distortion data such as robot arm force sensors require the measurement and calculation of the 6-axis distortion in a small space. The RX23E-A MCUs can measure the 6-axis distortion data and perform the inverse matrix calculations with a single chip.

Key features of the RX23E-A MCUs

- AFE block:

- 24-bit delta-sigma A/D converter: Up to 23 bits of effective resolution. Data output rate flexible at 7.6 PS to 15.6 kPS.

- Two 24-bit delta-sigma A/D converters that can start synchronously, allowing sensor temperature correction to be performed without switching channels.

- PGA (programmable gain amplifier): Rail-to-rail input PGA allows amplification up to 128×. Offset drift: 10 nV/°C, gain drift: 1 ppm/°C, and RMS noise: 30 nV rms.

- Voltage reference: Low temperature drift characteristics of 4 ppm/°C with superlative temperature stabilization.

- Excitation current source: Programmable current source with required matching required for 3-wire resistance temperature detector.

- Analog inputs: differential inputs: up to 6 channels, pseudo-differential inputs: up to 11 channels, single-ended inputs: up to 11 channels. All can be used as inputs to the two A/D converters.

- MCU block:

- CPU: 32-bit RXv2 core operating at 32 MHz

- Digital signal processing can be implemented with DPS instructions and FPU.

- ROM/RAM: ROM: 128 to 256 KB, RAM: 16 to 32 KB.

- Communication interfaces: SPI (1 channel), UART (4 channels), I2C (1 channel), CAN (1 channel).

- Functional safety: software load reduced by Self-diagnostic and disconnection-detection assistance functions for the A/D converter, clock frequency accuracy measurement circuit, independent watchdog timer, RAM test assistance functions using the DOC and other circuits.

- Supply voltage: 5V. Independent power supplies can be used for the AFE block and microcontroller. Voltages of 1.8 to 5.5 V can be supported.

- Operating temperature: -40°C to +85°C, -40°C to +105°C

The RX23E-A Group 32-bit RX MCUs comes in 48-pin QFP with 7 mm square and 40-pin QFP with 6 mm square. The samples of the MCUs are available now from Renesas with mass production planned for December 2019.