Whenever we hear the word floor cleaning robots, the very first name that comes to our mind is Roomba. No doubt, it has gained immense popularity, but it has some concerns too like it is noisy, it faces difficulty in transitioning. Another challenge that Roomba faces is crossing over from hardwood floors to high-pile rugs and thick carpets. With the idea of overcoming these challenges and enhancing the technological aspects of floor cleaning robots, Mr. Runal Dahiwade started the company, Peppermint Robots which builds autonomous robots.

One of the floor cleaning robots from the company is Peppermint Pro. It is an extremely efficient autonomous floor-cleaning robot that comes with advanced features to fulfill the cleaning requirements. To discuss the designing and working of floor cleaning robots their company builds, we had a conversation with Mr. Runal who is the founder and CEO of Peppermint Robots.

Q. Tell us about your journey with peppermint so far. How did you get into the idea of building floor cleaning robots?

Initially, I used to lead operations for an automotive aftermarket company, where we had a service vertical, which was extremely manpower intensive. As we were scaling up between 2017- 2019, I realized that the whole dependence on manpower for certain services becomes a challenge, if it is something very repetitive. We decided to do something with automation and that's how the journey to explore robotics started. We stumbled upon some great ideas and started building a car washing robot. With the guidance of mentors, we soon found that the commercial housekeeping space is a more evident, global, and available target market. We felt that any public or working space, such as airports, warehouses, industries, schools, colleges, hotels, and parks is cleaned every day, which is a repetitive and difficult physical task. Close to two and a half years back, the journey of Peppermint started.

We set up the company in May 2019 to formalize our efforts. We were blessed to have a stellar team and my co-founder, Mr. Miraj. When it all came together, we found that our hypothesis and the technology make sense. We love what we are doing and what the whole industry for commercial housekeeping stands for. Also, we are very excited about our robots, which are currently on the field in western India and will soon grow and scale across India and beyond.

Q. When it comes to floor cleaning robots as a common man, most people would think of a Roomba. Now, Peppermint pro being an industrial floor cleaning robot, how does it differ from it and what are its features?

We can categorize the floor cleaning space into two types. One is a personal space like home, house, small office, and then there is a public space like large offices, industries, warehouses, airports, railways, etc. Roombas are personal home cleaning robots with different grades and scales of machines, while we specialize and build commercial and industrial-grade robots. The first family of robots, we have built is for the floor and gradually we’ll get into vertical surfaces like walls and windows. There is a different type of floors that could be polished floor or cement floors. Our robots are good with six types of hardwood floors. Initially, we started with hard surfaces, but now we have a new dedicated line of robots built for soft floors like carpet and wood. Roomba and a similar grade of robots are household appliance-grade robots while what we build are large industrial-grade robots. Our smallest robot is a 200 kilograms, and tall table-like machine and that's how we are extremely different.

Also, with such large machines, there is very less tolerance for the mistake. If the Roomba accidentally hits your leg, it's probably acceptable, but if a 200-kilogram machine hits your leg that will not be acceptable. The approach of how its navigation happens and how its safety systems are built is very different. Three layers of safety and rigorous testing for over 18 months lead us to industrial-grade safe housekeeping robots.

Q. Your robots could autonomously navigate in an industrial environment and do the cleaning autonomously. Can you tell us about the intelligence and the algorithm that's behind your robots that enables this autonomous driving?

The current range of robots, we have is of floor cleaning robots. There are different types of floors. First is a large and contiguous open area like convention centers, airports, and parking lot needs to be clean in a more structured fashion taking the least time possible. For this, we use our virtual machine and create our pathfinding and navigation system stack from the ground up. Second is long, narrow stretches of floors like industrial gangways, lobbies. Such areas demand a smarter way of addressing as these areas will be used by everybody as well and there could be any other equipment or material moving around. We will either do long, narrow stretches at a time, so that neither we become an obstacle nor does any other moving object become an obstacle for us. We follow different philosophies when it comes to navigation stacks. The algorithm we have is based on structured cleaning in the minimum time possible. The third one is Mix use case in which we mix and match our stack, and deploy them on the field.

Q. On the hardware level, how does your robot sense the environment? Does it have any sonar to do floor mapping? How do you sense the environment around the robot?

Robots don't have eyes, we have to put eyes to it for which we use different sensors for varying sensitivities and merge that data for our integrated view. We use primary localizing sensors, 2-D or 3-D depth cameras for sensing more sensitive information in the environment. Apart from this, we have ultrasonic sensors and in the future probably radars. These three sets of sensors are used to deal with the different sensitivities of the environment because as a large robot, we have to not only look at the environment; we have to be mindful of people and machines around, and other features like pillar furniture, we also have to be very accurate about things like glass. Glass is transparent, sometimes it's very clean, and then the camera may or may not catch it very well. We have sensors to deal with that too. We use these different sets of sensors and bridge them together to make a more consolidated understanding of the environment. The higher focus is on the front end of the robot, but there is also a secondary set of sensors towards the rear.

Q. Being an autonomous floor-cleaning Robot, how does peppermint pro ensure safety on the factory or industrial floor?

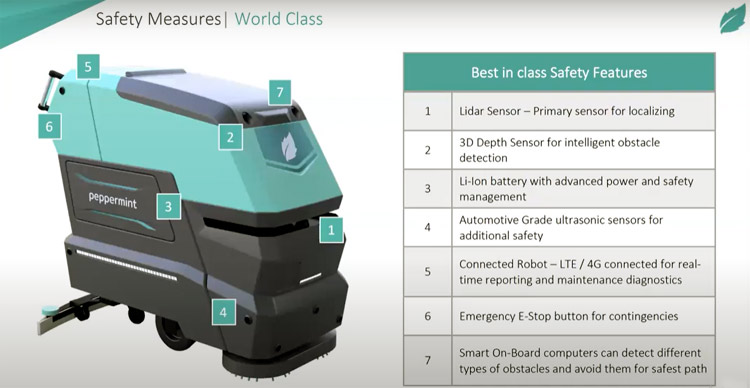

There are seven different layers in a scrubber dryer robot. The LIDAR is the primary sensor for localizing. We also use cameras and depth sensors for obstacle detection. Cameras allow us to capture feed that can be used to detect a lot of things, various kinds of people, furniture, machines, forklifts, baggage trolleys, etc. It’s important to note that such large machines have substantial battery packs and it's important to have an automotive-grade BMS. We have partnered with a company to get those done as per automotive safety standards. Apart from this, there are ultrasonic sensors, and the whole system also has physical buttons which are called emergency stop buttons. The onboard computers are so smart that we can detect a lot of external stimuli. For example, if there's a staircase, the robot should be able to detect it and stop. All of this is also connected back to our systems for enhanced learning from all the data. We have an option if certain customers wish to have real-time updates for the robots then we can do that. It's a seven-layer system with seven distinct components that work together to provide a great, safe technique of operating.

Q. Peppermint pro is designed, built, and manufactured in Pune, India. What type of challenges did you face while setting up a robotic manufacturing plant in India?

Pune has an automotive manufacturing ecosystem, many large companies, good automotive grade fabrication experts, and vendors, and many other things. We leverage that ecosystem when we design the Peppermint pro and newer machines like scrubber dryers, carpet cleaners. It’s an autonomous moving machine, which cleans floors and it carries water. Initially, some of the challenges were to be very sure of our sub-assemblies. There are six sub-assemblies in our robots and every subassembly does its individual function, but they all have to work together. It's one thing to make prototypes, but very different to batch manufacture, and eventually mass manufacture. As a team, we had to deep dive into it, and as there was just no other way to do it. We make five or eight robots in a batch, depending on the cycle and currently, we have batch manufacturing of two of our robots in the pipeline.

We have some really good supportive vendor partners who are specialists in certain areas. Getting it all together is a really big challenge both physically and functionally as mechanics should work together, fit together, and look proper. All these systems talk to each other and eventually, floor cleaning happens beautifully. Peppermint is best in class as we have a patented cleaning technology tech stack, which cleans the floor in a better way.

Q. So peppermint being a robot, would have had a lot of mechanical and electronic components going hand in hand. How did you manage to set up the supply chain here in India? Did you face problems in procuring the right components for manufacturing?

We were lucky to have the right team members very early who have worked on different use cases, but similar subsystems, having deep experience in manufacturing. Moreover, the rich automation ecosystem of Pune helps a lot. As we have six sub-assemblies, we have the supply chain procurement of each of those sub-assemblies independent of each other. Scouting for the right part or material takes time, but once we are good, we try to narrow it down to one or two vendor partners and then start fabricating stuff. Some challenges which occur are usually in importing parts that are not yet made in India and the COVID situation over the last almost one year now hampered the whole supply chain globally like shortage of old semiconductor or conductor which is impacting our work. We had to go to a plan B on one particular circuit to work. A colleague of mine - Vaibhav, who leads our entire packaging and product excellence, has been instrumental in getting these pieces together.

Q. As you told that there is a GSM module onboard which sends all the sensor data of peppermint to a cloud platform. What kind of data are we collecting here? And how are you utilizing this data to improvise your services and performance of the robot?

We gather data for real-time analysis and then we dump it. Being autonomous robots, no one is looking at the robots when they're cleaning the area. There has to be some accountability to what's going on to the customers or the facility management companies who are overseeing housekeeping. We decided very early in our journey, that there has to be some visibility of how effectively the robot is working. So, based on this principle, we have real-time data which we gather from our robots and then differentiate it into categories. One is operational data which is about how much floor is cleaned in the shift or how much water is there and either the battery is properly charged or not. On the other hand, there is another bucket of data, which is maintenance data. As a large machine with lots of moving parts, this data helps to know what the health of motors is, are the laser and sensors getting data accurately, and if there is any red flag, you'd rather have a preventive approach to it rather than fixing it after it is broken. We use that second maintenance data to take rich decisions on servicing of the robots.

There are two types of services; one is very tactical where we double-check all the data related to sensors while the other one is more strategic where we know about the parts of their life cycle. To manage replacement or rectification of that competence we use operational and maintenance data. The operational data helps in giving visibility of operations, while the maintenance data helps in planning the machine's uptime and maintenance quite well. It simplifies our life as everyone has visibility to what's going on.

Q. Both the client as well as Peppermint has access to this data. Is there any data analytics being put on this data that you're gathering or who's monitoring these parameters?

Our data stack peppermint dashboard has just started this financial year. The intention is to do with the permission of our customers. We don't store any data at our end for any other use and we would be analyzing the data for many things, for example, the robot is in a mall or an industry and there is spillage of oil on the floor, which is a safety hazard, as anyone would slip over it or it will attract insects and spoil the whole floor, while the robot will clean such a data we will know how that spillage happened and try to look at the source of an external event. Similarly, there are many such incidents, which we can recognize by doing post-processing of data and draw very intelligent outcomes. We recently started work on one customer's request which is the actual cleaning index of the floor and the air around it. Since these robots are cleaning certain sensitive areas in warehouses where sensitive material is kept, we are trying to catch things like odor or any particular matter in the air, which can trigger a safety alarm or healthy database being sent back to the servers. We're starting with safety as step one, so like to start spillages on the floor, air quality odor, or any toxic elements in the air, that sort of data which is meaningful to certain types of customers. We're very sensitive about it like pharma industry, paint industry. These are the early stages of our peppermint dashboard, but it's lovely to see it is all happening in real-time.

Q. Who are the current clients of Peppermint? Can you give us a rough case study on how your robots are deployed and utilized on the client field?

We have two large types of customers. One is large facility management companies who are experts in housekeeping operations and we supply machines to them, and they, in turn, take it to the customers. So, that's one bucket through which we get access to large industries like GHW steel. We have certain customers with direct engagement because they have automation or robotics as a clear mandate. We have different types of customers like Associated Capsules, Mapro Foods, Caravan Logistics, etc. Apart from this, we have customers lined up outside India as well, starting with Dubai as our first territory outside India. Most of our customers have more than one robot so it gives us confidence and encouragement.

Q. How does the deployment take place now? Do you give any sort of orientation to the maintenance team there and train them to take care of the robot?

It's a three-step process. Firstly, we have to go and map the place. This is a robot-assisted by an engineering process, it's a one-time process we undertake and we prefer to do this because it builds very clear data about the environment. This may take one to three days and depend on the size of the deployment site. The second step is to get the robot to start cleaning and we do a supervised run for a day or two just to be double sure if the robot is cleaning everything properly or not. And then, finalizing its positions of where it will be charged and where the water will be changed, because the everybody may have a different way of giving us access to water, plumbing connections, or electrical connections. The trend is to finalize the workflow and hand over the robot to the local operations team, which could take somewhere between two to four days, depending on the size of the area. We have a very dedicated engineering deployment team for this to lead the whole exercise for peppermint. The whole process wrapped up within a week and we hand over the robot and move on to the next site.

Q. How do you see the market for industrial floor cleaning robots in India and around the globe?

Globally, in developed countries, there are many floor cleaning robots on the floor, therefore; it's easy to say that the awareness, use case, and benefits are established. It's a different curve to entering those markets. And as now, betterment is available in certain countries in the Middle East and we are getting exposed to such markets. In India, we are in the early stages of the adoption of robots, which is great news, because in such a dense market like India we have a very large number of high population density cities that give us access to a large density of robots in a cluster. We are in the early stages and believe that the potential is truly endless, with more new infrastructure getting built in India, getting bigger airports, bigger malls, bigger industries, public parks, and convention centers. We are slowly getting to a place where our public infrastructure is truly getting upgraded in the last decade. It's only a matter of time that we start getting organized methods of cleaning, housekeeping, and facility management and robots play a very crucial and transparent role in that. The application simplifies the process, speeds it up, and makes it more cost-effective.

We are super excited about India, as well as our overseas deployments, as this is just the beginning of this journey. Some of the more mature markets have been there for the last three to five years and we allow different ways of educating and entering with our robots in those markets.

Q. Is peppermint working on any new products or variants? What are your plans for the company in near future?

We are in the middle of the launch of our second family of robots. The objective for us always has been to completely address horizontal cleaning solutions first, which is all types of floors, whether indoor or outdoor, for different frequencies of cleaning. We started with a midsize 45-liter scrubber dryer and have recently launched a 100-liter version which is slightly larger. Now, there is a new family of robots altogether, which are mid-size robots for carpet cleaning, floor vacuuming, smoking indoors. And in the latter half of this year, we would have launched our outdoor sweeping robots as well, and probably to our knowledge that will be the first-ever in class. We are very proud of what we as a team have been building towards and I think by the end of this year, you will see us as a five robot offering doing things different indoors and outdoors.