Industries have seen an array of growth, which has often come from industrial robotics and automation. What makes factories extremely cumbersome, extremely difficult. At the same time, the adoption of automation itself is a tedious task. Now that’s where Cobots come into picture. It is a technology under the bracket of collaborative automation called Collaborative Robots whose deployment into the factory is a matter of half a day. So, in 1/2 a day's time, what was dumb, dirty and dangerous job, which was done by human beings, adding no value to a job, now can be fixed by bringing in a cobot. But the human being is not technically replaced. In an exclusive interview with CicruitDigest, Sougandh KM, Country Manager of India, Universal Robots explains how robotics manufacturing can be increased in India, the usefulness of cobots, the challenges the industry is facing currently, and various other aspects.

Q. Currently, where do you see India stands in robotics manufacturing and deployment, especially in the industrial sectors? Kindly paint a growth picture in terms of global perspective?

India becomes a very critical market. It's definitely the digital media which is going to drive the future, reaching out to our markets. India becomes a very critical market when it comes to the perspective of automation and robotics. Nowadays, we see a lot of initiatives driven by the Government of India indicating where our manufacturing can take us to, especially in a trillion-dollar economy. It's high time that we move towards the direction of automation. With the help of cobots, the dumb, dirty, dangerous job gets replaced, while the human is now used for a more intellectual job. So, this is where I feel the growth of cobots into this market becomes relevant and automation in India will take a steep demand largely around this topic.

Q. As per media reports, robotics usage has increased all over the world, but there are grave concerns regarding its manufacturing growth. Kindly highlight the global challenges and what are the steps required to boost its growth in the industry.

If India needs to spike itself into global manufacturing, one basic thing is there must be a revolution that should come in the space of its adoption. Now, where does that adoption come into picture? Only a few of us know that if we have to adopt the technology, we should be aware of that technology. So, education becomes a very critical element in this picture. How much education are we able to provide to the users or the growing engineering segment and all these people? And then if you're using Robots in your college days, then you want it on your factory floor. If you are using it on your factory floors, then you think as a manager that there could be an increase in your productivity.

The second aspect is policies, which define a lot of things. India is on the brink of making such policies. We saw a lot of policies driven by the government in order to boost manufacturing such as the PLI scheme. It is a phenomenal mechanism which enables a manufacturer to see where he can grow. If it's a mid-size company, he sees this as an opportunity to become a large sized manufacturer because of the incentives and others.

Q. Although robotics is considered to be a boon for the industry, there is serious concern about human workforce reduction and unemployment. Do you agree with this statement? What is the actual scenario?

So, there is a company with which we've been working for a very long time, known as Arvind Eye Care Hospital, which makes intraocular lenses. When they bought our robot, they had 100 people working in their factory. Today, they have close to 6000 people working in their factory and they've been using cobots. So, what I understand is it's not robots that take away jobs, bad management decisions usually take away jobs.

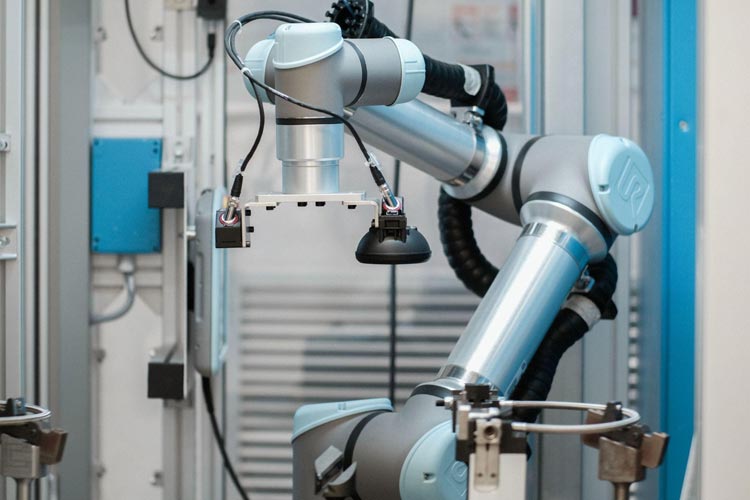

With the help of cobots, the productivity of Arvind Eye Care Hospital ramped up to 17,000 lenses today. They are also able to reduce their cost of manufacturing. So, we will not be able to look at them completely from a manufacturing factory floor alone. You should take a holistic approach. If you deploy automation, you need to know where do you save your cost in the longer run, does it reduce your cost of manufacturing goods? Manufacturers these days consider robotic automation and robotic solutions must be deployed. Cobots become handy because it's an arm which helps humans and robots to work together. That brings in an extremely huge advantage. You're not removing your labor force, you're retaining those 100 employees, but bringing in more machines. So, what happens? Your man to machine ratio completely changes. Humans do more intelligent jobs and machines do the tedious jobs, and the throughput is of high quality.

Q. When was Universal Robots formed and what is its mission and vision behind its formation? Do you wish to highlight any of your investment plans in India in the coming years?

We are a global company based out of Denmark in a place called ODENSE. We've started the organization since 2005 and since then, we have sold close to 75000 cobots. It ranges from, you know, CNC tending, which is machine tending, palletizing, packaging, electronics, electric vehicles, EV battery management systems and many other domains.

Universal Robots specializes in machine tending, palletizing, and welding, extending it towards electronics and in the education domain. However, the Indian operation started in 2016, we've been a part of that. We have a sales team, technical support team and after sales support team, available in India. Speaking of our business model, we operate through our distributor channel. We go through our distributors to the end users and support them build solutions and applications. When I say distributors they are also system integrators. Our authorized training centers are coming up in India, so that's the plan as we scale in the few years from today. You will see more investment coming into the training set up in India.

Q. What are the various kinds of cobots/bots you are offering in the industry? Can you highlight any of your upcoming cobots, which you think will be a game-changer in the country?

We are a robotic arm manufacturer called Collaborative Robots from Universal Robots. Our company has a lineup of five robots which range in payload from 3 kilos all the way up to 16 kilos. Very recently, we've released the next generation of cobots called UR20 robots that can lift a payload up to 20 kilos, so this is the entire fleet. So, all of them are collaborative in nature, work alongside human beings and that's how it is. Coming to the vision and mission of the state company. We have a mission to make automation accessible to all. That's what we're driving towards. Our firm wants to create a world where people work with robots and not like robots. In India also, that's the perspective despite so much of labor and so much of the machines we have, an array of opportunities for us to work together. Now, we have the UR20, which is already on the market. We have a few customers who've already bought that in India. You will see notifications of that coming in the media soon. We have some major events happening globally.

Q. For the past few years, a lot of new companies have started arriving in this ecosystem. What are Universal Robot’s biggest differentiating features that help you stay ahead of the competition curve?

I can proudly say that we are the market leaders when it comes to innovation of a technology of this sort. So, in 2005, when we started this company, we were the Pioneers in this domain. We are the only company even till date which has 75,000 Cobots deployed across the world. That itself is a huge milestone for us because we have learned so much through this journey. Good, bad, ugly. Whatever you say it, but at the same time, we've learned so much new things which are making cobots user friendly, usable for the end users. We want to really hear from most of these customers, what's their feedback and make sure we make improvements into our product to make their life easier.

It gives us huge mileage when it comes to what the customer wants and we are able to offer. We have an extended ecosystem called the UR+ ecosystem, which is a basket of technologies and is more a solution provider. For example, you have bought a robot and you have really no understanding as to what it can be used for. Then, you can visit the UR+ ecosystem and you will have a clear idea.

Q. Going forward, what will be your roadmap in the coming five-seven years?

We are known as a company which is very well versed in the application domain, right. So, we have applications in machine tending, palletizing, electronics and other segments like welding. But, we also need to see how much of that can be replicated in India, because it is a huge hub when it comes to these domains. Like you have at least about 50,000 CNC machines in India or more. You have so many packaging companies’, food and beverage manufacturing companies, which have a potential to become tier one companies. So, we want to see how much of a partnership we can have with most of these companies through our channel partners and through directly. At the same time, we also want to understand how much engagement we can have with the OEM businesses.