Burgeoning to become the Tesla of consumer appliances, Atomberg Technologies is an IITian start-up founded by Manoj Meena and Sibabrata Das in the year 2012. Currently, they design and manufacture India’s Most Energy Efficient Fans commercially known as the Gorilla Fans. These Fans are rated only for 28W compared to the ordinary fans which would stand between 75W to 80W, this makes them to consume 65% less power than any other fans. The magic behind this fan is the Atomsense Technology, in which the company has cleverly engineered a Controller to drive the BLDC fans without sensors by just measuring their back EMF and Coil Inductance. Interested in their amazing work, we had few question to know more about the company and its products for which Manoj was generous enough to give the following answers.

Q. When was the Idea of Atomberg Fans originated? How did the company get off the ground and how is it now?

I had passion for robotics and electronics since my college days, and was extremely involved into robotics activities and competitions—all this as a part of my curiosity-driven learning. Then, I founded Atomberg in 2012, for first three years I was bootstrapping in a project mode, developing data acquisition, motor control and process control systems. As the years passed, I realized that we were working in a not scalable project mode, so started thinking to build something scalable from our motor and electronics design expertise. In 2015, I came out with thought of making energy efficient and smart ceiling fan. With Sibabrata Das joined as co-founder and a small team of 5 member, we made our first prototype of BLDC motor for ceiling fan in April 2015, this was our turning point to foray into motor-based home appliances market in India.

Today we are a team of 200 members and more than 2.5 lakh Gorilla fans are running in India and other countries like Bangladesh, Ghana and Nigeria. And every year, using these fans instead of old 75-80 watt fans is resulting in an approximate saving of 36000 tonnes of CO2 emission, a yearly saving of more than 2.5 million $ and 38 GWH of electricity. The company has also been listed under top 30 in Asia by Forbes.

Q. What were the perks of being an IITian that helped you while getting started with Atomberg?

The idea of Atomberg itself was incubated at Society for Innovation Entrepreneurship (SINE) which is inside IIT Bombay. In the initial 3 years incubation at SINE, IITB was really helpful for us to get a kick start of RnD activities. It was a good startup ecosystem and some exposure to the investor network. Also got good guidance from relevant faculties and had access to the various labs for initial development and prototype testing.

Q. How are Atomberg’s Fans different from the other fans that are already in our homes?

Atomberg fan runs on our revolutionary BLDC motors technology optimized for ceiling fan application. It consumes only 28W (65% saving) where ordinary fan consumes around 75-80W, this makes it to run almost 3 times longer on an invertor. Since motor runs on DC power inside, output of fan is constant even with input AC power variations. BLDC motors do not create any humming noise and run very cool. With 3 years warranty, our customers are saving up to INR 1200-1500 annually. So, they are not only recovering the complete cost of fan within warranty period but also saving afterwards. Saving of greater than INR 10,000 could be easily realized per fan in the lifespan of fan. Adding more to it, all our fans come with a smart remote with features like TIMER and SLEEP. A smart LED interface at bottom of fan gives a WOW factor to our user.

Q. It’s really cool to have a fan with a remote control, are these normal IR ones that are used for TV’s? Can I control all my fans with a single remote?

The Remote works with Simple IR Based technology. Remote is normal IR based and all fans could be controlled from a single remote. Our Remotes are compatible with all our Fans.

Q. What is the price of a single fan for a commercial customer? Where can I get one?

Our fan comes under brand name ‘Gorilla’ starting from INR 3000 – 4200. You can get your ‘Gorilla’ online from Amazon, Flipkart, Paytm, Pepperfry, Atomberg website. We have few retail outlets in Mumbai, Pune, Ahmedabad and Chennai.

Q. Atomberg Fans are super-efficient because of the Atomsense Technology; can you explain us more on that?

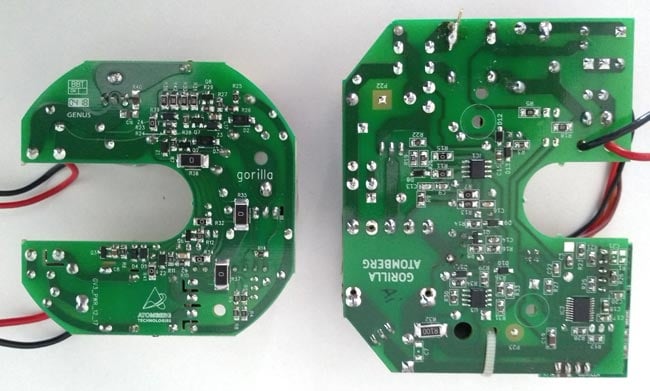

BLDC stands for Brushless Direct Current, as name says BLDC motor has no mechanical brush for commutation of the windings. Commutation is deployed by help of smart electronics which is responsible for sensing the magnet rotor position with respect to stator and controls the motor driving switches. Winding magnetic field react with field of permanent magnets on the rotor to develop the required torque. Like, induction motors there is no current flow in rotor, it has permanent magnetic field. As a result, rotor losses are negligible.

Electronics is programmed with AtomSENSE algorithm. This is the motor tuning and calibration algorithm which is responsible for precisely sense various motor parameters in real time and control the motor in a close-loop by measuring the back EMF of each coil. There are various motor parameters like rotor position, winding temp, input current, dynamic load etc. which need to be preciously measured for driving the motor efficiently with zero noise. Also, to ensure a smooth start the inductance of the coil is also measured.

An advanced FOC (Field Orientation Control) method is implemented using sensor less rotor position sensing techniques and commute the stator winding accordingly. FOC is small part of the AtomSENSE algorithm, a lot noise filtering and processing is required to capture the data accurately in real time. Motor control flow has various exception handling routine implemented to take care of exceptions like external loading from wind, fan halt, blade bending, motor wobbling, ambient heating (affects motor coil resistance), flux saturation etc. Protection handlers are other layer in also which ensures that the motor runs safely, protection from voltage surges, current surges in coil, peak power locking and heating etc is implemented. Supporting electronics hardware is also implemented wherever required. Motor phases are excited with smooth sinusoidal current profile generated by motor driver, this reduces harmonics which cause noise and power loss.

Q. What magnets are used in the BLDC fans? Is it neodymium?

Today we use Ferrite magnets for ceiling Fans and neodymium for wall mounted fans. The reason is that Ferrite magnets are cost effective and easily available in India, this is a good choice in ceiling fans because there you will need more number of magnets of bigger size since the hub is bigger. Whereas the neodymium magnets form china are smaller yet powerful and hence can be used in places where the product has to be compact like the wall mounted fan with a smaller hub.

Q. What are the other application/products that can leverage the Atomsense Technology?

Apart from ceiling fans and wall mounted Fans Atmoberg has already started to work with Air Coolers. The other products that we are currently focusing on are Fan Motor based appliances like Air Coolers, AC, Pumps, Mixtures, Washing Machine etc could be targeted.

Q. How long did you take for building the prototype and to scale up for full production from there?

At 2015, with more than 10-12 iterations, we came up with production model in about 6 months time. Then, at Navi Mumbai setting up initial production and developing supply chain took us another 6 months time. After that we have been continuously upgrading our product design to optimize cost, enhance performance and improve quality. At backend, we keep doing automation and assembly line upgrades to meet the sales demand.

One is getting the prototype ready because it take 6 months time, and then at the same time you have to make infrastructure ready for production for which you have to set up machinery and establish supply chain. There are two different activities here and it took around 6 months for each. We were lucky enough to get the prototype running in 6 month because of our earlier expertise in motors.

Q. How was your pilot lot manufactured? What were the difficulties you faced back then?

Pilot lot of first few hundred units was assembly in a much unorganized fashion by our RnD team only. This gave us good understanding of assembly flow and required machinery/ setups. Soon we build a full-fledged assembly line with trained operators. Most difficult part was to setup a robust and reliably supply chain and vendor base. Working capital management and managing cash flow in such industry was very new to us but we learned it in a hard way with time.

During the initial pilot, team was very small. There were only 7-8 R&D people and we had around 400 fans to be manufactured for which the customers were waiting. So our R&D team itself manufactured it, which gave us good understanding of the manufacturing process. This happened for the initial 6 months, but then the manufacturing set-up was established. Today we have lots of operators and machineries for dedicated tasks.

Q. How the components and other supply chain were was set-up for the initial Pilot Lot?

Since the motor was completely new, the center part of the hub which is an aluminum die casted part had to be made on our own. So we had to make an aluminum die casting tool which took us around 6 month time. Then, there are some plastic parts in the motor for which we had the tools designed and then fabricated with 3rd party vendors. Then we approached ceiling fan vendors who manufacture these fans in masses, and we handed our tool to them. For the Fan blade which is just a sheet metal, we developed a simple punching tool.

This is what happened initially but then now; to scale capacity and obtain good quality we had set-up our own dedicated vendors today.

For electronics components we had various EMS (Electronic Manufacturing Services) parties, we used the one that was available to us in Mumbai. Basically once the design of PCB and components is finalized, you hand them over to these parties for manufacturing and assembling. After that the boards were then tested and analyzed by our engineers before it gets into the product. We follow the same procedure even for bulk production since it makes a lot more sense.

Q. How does your R&D and Production plant look like? Where do you spend most of the time in your company?

We do lot of process RnD and automation activities to enhance capacity and quality. So, it is 50-50. Half my time is spent with R&D while the rest with Production.

Q. As an electronics product manufacturer, what is your preferable place to buy electronics components from? Both for R&D and production level.

Today we are the leading manufacturer of BLDC motors in India, we get very quick support from companies like TI, STM, Infineon and On-Semi etc. We are able to get quick samples, evaluation boards and supporting infra from their team for our RnD activities. For manufacturing, we deal with their authorized sales partners.

Q. For a consumer product Development Company like Atomberg, was it challenging to set up a manufacturing plant in India? What could have helped you in the process?

It requires a good experience of manufacturing processes and sufficient capital to deploy the plant. Initially it makes sense to outsource some of the components and understand the processes. Gradually process should be brought in-house one by one when you reach sufficient volume when it makes financial sense. In-house manufacturing also gives a better control over the product quality.

Q. Apart from celling fans, what are the other products that are currently being focused on at Atomberg? What are the company’s future plans?

In the long term, we want to become the Tesla of Household Consumer Appliances by combining the virtues of energy efficiency and smartness in all our products. Currently, we are the number 1 player in BLDC ceiling fans in India. We have also launched pedestal and wall mounted BLDC fans recently. Looking at current growth and revenue, we are on track to have INR 500Cr revenue from fans by 2022-23. Since our core expertise is in motors, we are also exploring other appliances like coolers, air purifiers, air conditioners etc where we can use our super energy efficient BLDC motors.

Q. What are the major awards & achievements you received so far?

For such a big impact on energy efficiency and electricity saving I have got the following awards and recognition:

1. Awarded 'National Entrepreneurship Award' 2017 by Govt of India.

http://pib.nic.in/newsite/PrintRelease.aspx?relid=173358

2. Winner of 'Global Climate Solver Award' organised by 'WWF' (World Wildlife Fund)

https://www.wwfindia.org/about_wwf/reducing_footprint/cce/our_work/climate_innovations/

3. Winner of 'Global CleanTech Innovation Program' in Energy Efficiency category organised by 'United Nations Industrial Development Organisation' held in San Fransisco, USA

https://www.unido.org/news/clean-technology-innovators-receive-global-cleantech-innovation-awards

4. Got recognition from the Prime Minister and Niti Aayog as ‘Champions of Change’ in the startup ecosystem

5. Got to the list of 'Forbes 30 Under 30' India 2018 in 'Science & Green Technology' category

http://www.forbesindia.com/thirtyprofile2018/manoj-meena--sibabrata-das/1679/43

6. Got to the list of 'Forbes 30 Under 30' Asia 2018 in 'Industry, Manufacturing & Energy' category