The Great American Businessman and Inventor of light bulb – Thomas Alva Edison once said that “We will make electricity so cheap that only the rich will burn candles”, which certainly has become the case today. From small house to paved roads to big industries, we can notice AC lights illuminating our environment after the sun goes down. Earlier lighting systems employed different kind of bulbs like incandescent light bulbs, Compact Fluorescent Light bulbs (CFL) etc, but today with the advancements in LED light technology these Incandescent and CFL bulbs are quickly being replaced by LED lights. The global LED lighting market has seen a prolonged growth with a size valued at USD 45.57 billion in 2018.

While it is known that LED lights are almost 90% efficient than incandescent bulbs and has a better lifetime than other AC bulbs, it still suffers from one setback. That is, LED lights are driven by DC voltage, but all our mains power supply is AC. This has pushed designers to use an additional component called LED driver which is nothing but a type of AC to DC converter. This driver will convert the AC power from mains to a suitable DC voltage to power the LED light. But, then the AC driverless LED bulbs were introduced which can be directly plugged into AC mains without any external driver modules. In this article we will learn more about Driverless LED systems and its evolution over time.

Why Driverless LED systems?

The major problem with the traditional high power AC to DC switching LED drivers is the power loss associated with it. These traditional AC LED drivers use switching topologies and resistors to control the LED current, this switching causes heat which reduces the efficiency of the system. Also this additional circuitry leads to the increase in overall cost of the Light bulb. This is why in our previous article we discussed about a low-cost LED driver system and even built one to test its performance.

Another terrific problem of the AC LED drivers is the flickering effect. As most of us have noticed the old LED driver circuits have a flickering effect. In maximum cases, these traditional AC LED driver circuits use half-sine wave at twice the frequency of the power line. That means, in a 50 Hz frequency power line, it produces almost 100 flicks that can be detected by the human eyes and it is harmful. This should be eliminated. So, modern technology is introduced which uses few passive components instead of the traditional AC to DC converter using switching topologies.

Driverless AC LED Lights - Working

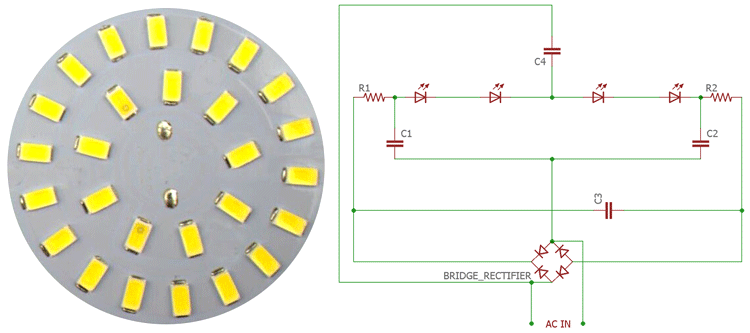

The Driverless LED system has something called as an AC LED light engine. But, what is an AC LED light engine? An engine in general is used to convert one form of energy into the other. For example, a motor engine is used to convert heat produced by the fuel to the movement of a shaft. Similarly an AC LED light engine is used to convert Electrical energy to the lumens of light.

An AC LED light engine is a mechanical fixture or a circuit board that has LED chips mounted in it with all electrical connections. It is a readymade form of light source that can be easily fixed into an AC socket. It helps the LED bulbs to act as a direct substitute for other conventional lamps.

The development of this AC LED has several stages. It started by simply connecting standard LEDs in series to match the combined forward voltage of the LEDs with the maximum AC input voltage. It sounds like a good idea to light up those LEDs without any driver, but it was not successful. This design has a major drawback, AC changes its polarity from positive to negative for every cycle and due to this, on every positive cycle the LEDs are forward biased (turned on) but in every negative cycle, the LEDs are getting reverse biased which makes them turn off.

First Generation Driverless LEDs

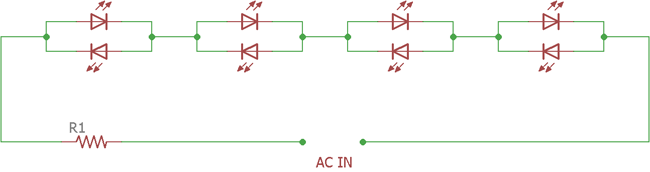

So what is the solution? At this time, the first generation of driverless AC LED lights was introduced in which each segment of the LEDs is replaced with an anti-parallel pair, just like the below image.

In the above image, LEDs are connected in an anti-parallel way. In every positive cycle, one side of the pairs is forward biased and the other side is reverse biased but in the negative cycle, the states get changed and the other LEDs lit up. The current here is limited by a single high power resistor R1.

The positive side of the circuit is the efficiency. The efficiency is very high. The in-phase current and voltage waveform passing through the circuit creates a high power factor. But, despite the above mentioned positive side, the first generation of the driverless LED light engine is a failure. It is because of the poor Flicker index and the double number of LEDs than required. It produces a flash effect which is easily detectable by the human eyes and half of the used LEDs remain off in any given times.

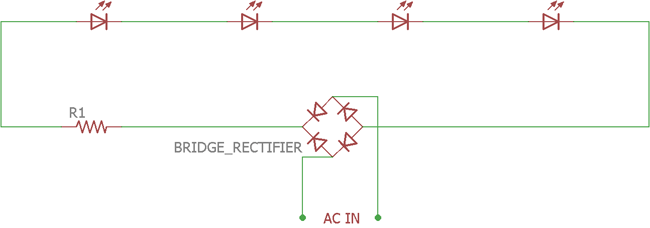

Second Generation Driverless LEDs

From this drawback, the Second generation driverless AC LED engines are developed. This time the goal is to lower the LED counts. It is only possible if the AC is transformed into DC. Therefore, a bridge rectifier diode is included in the second generation driverless AC LED light engines. Other than the rectifier diodes, everything in the circuit is unchanged.

Like before the resistor R1 is controlling the LED current. Now each both negative and positive cycle are passing through the LEDs making them to remain turned on during both cycles.

Third Generation Driverless LEDs

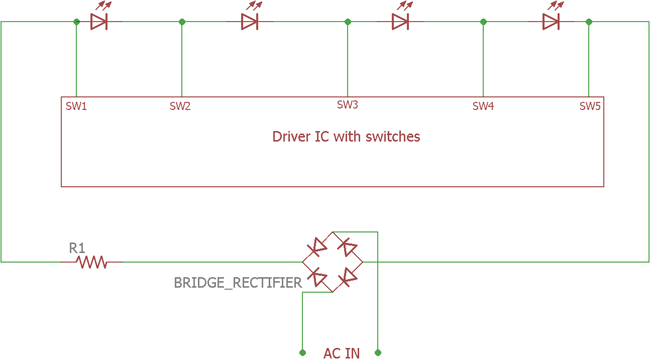

The third generation of AC LED engines is introduced to increase the efficiency and to get an enhanced flicker index. Switching controller is added in the circuit which can individually control the LEDs to a certain level where the power line voltage is the same as the LED voltage. The current limit function is also available in the integrated switching controller and that can be reconfigured using external components. Such a circuit could provide almost 80% of efficiency and .30 to 0.35 flicker index.

Fourth Generation Driverless LEDs

In 4th generation driverless AC LED engines, the controller is eliminated and passive components are used to compensate with the manufacturing cost. Also, the efficiency is superior with a high power factor and enhanced flicker index.

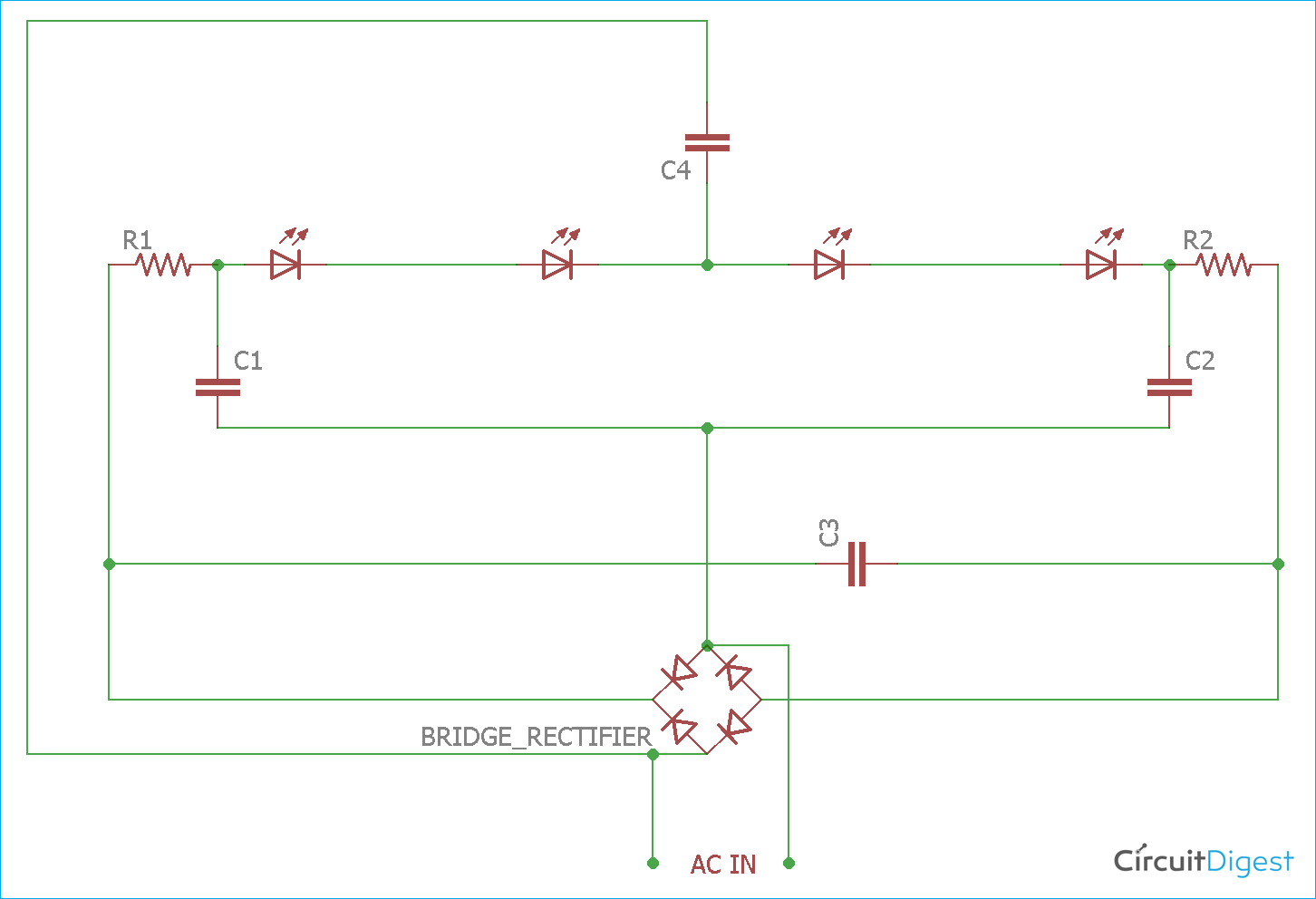

The circuit works with two independent current pulses, which are capacitively limited current pulse and resistively limited current pulse. Those current pulses are feed into the LED string in a way that the LED string gets two current pulses per half cycle of the line voltage. Below image is a fourth-generation low power driverless AC LED light engine circuit.

The working of the above circuit is quite interesting. During the first half cycle of the input AC, the current goes through the resistor R1 and eventually charge of the capacitor C1 and return back to the bridge rectifier diode through the second string of LEDs, charging the capacitor C2 and through the resistor R2. During the negative peak, the capacitor C4 discharges the C1 and C2 correspondingly and pushes the current on the second string. So, on each cycle, the current which is required to light up the LED strings are not flowing entirely through resistors. Almost 40-50% of the total current passes through the resistors which increase the efficiency up to 90% by reducing the heat dissipation.

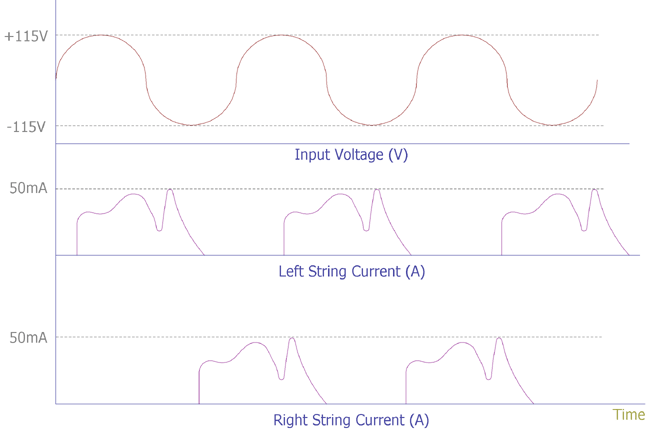

The input waveform of the LEDs and the input AC Voltage can be seen in the below image.

The above graph shows three plots which are, Input voltage, Left LED string current and Right LED string current over time. In 230V line voltage, the LED strings are light up alternately. It is a very fast transition in the mili-second range.

Advantages of driverless LED Light technology

1. These driverless LED lights are easier to manufacture. The cost is reduced and requires very low maintenance.

2. Due to improved Flicker index, it can be used in high bay lights. Also, office, room, education sectors are using driverless AC LED lights.

3. With the LED driver removed, it enables reshaping feature. LED products can be made in different shapes and sizes.

4. Easy and quick installation is another great feature of driverless AC LED lights.

Manufacturer of Driverless LED Lights

Driverless AC LED light is sold like a hot cake today. Different manufacturers are producing a different kind of driverless AC LED technology. China is one of the leading suppliers of driverless AC LED light. However, LEDs with very high forward voltage with high Lumen is also getting manufactured by several companies. High forward voltage LEDs provide low component count in driverless AC LED system. Popular Driverless AC LED manufacturers in this segments are Cree, LUMILEDS, SAMSUNG, NMB Technologies, Opulent etc.

What will be the value of R1, R2, C1, C2, C3, C4 for this driverless LED lights circuit for 25 LEDs or how to calculate the value of these components?