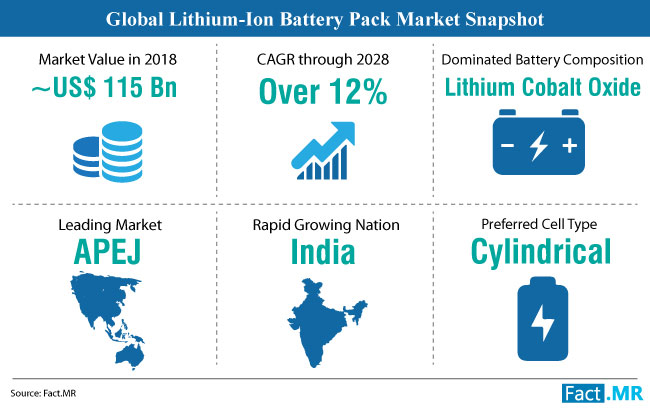

With the world moving rapidly towards the future of e-mobility, the lithium-ion battery industry is becoming one of the most critical industries that are shaping the energy storage revolution. Lithium-ion batteries are witnessing heavy demand in various applications, as these batteries play an instrumental role in the growth of today’s power and transportation industries. The valuation of the global lithium-ion battery pack market jumped from US$ 115 billion to US$ 127 billion during 2018-2019, and the market revenues are expected to escalate 3x in the next decade.

The world is moving from the traditional energy sources and solar cells and lithium-ion batteries are becoming indispensable for a wide range of end-user industries, such as automotive and consumer electronics. Manufacturers are adopting efficient, transparent, and flexible manufacturing processes to improve productivity and speed up the time to market. Reducing production costs with advent of next-generation manufacturing technologies is likely to remain the primary focus for market players in the coming years.

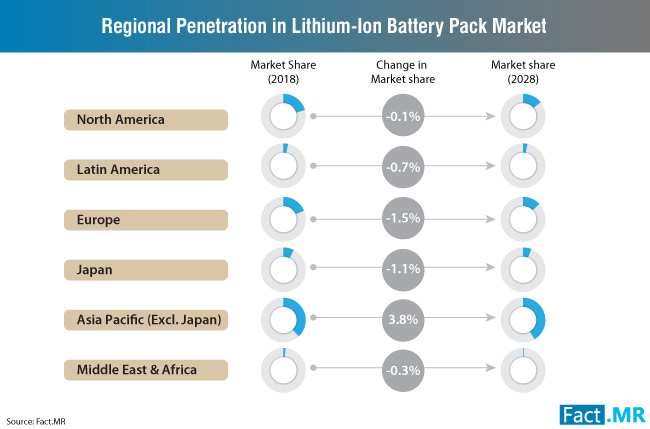

Developed regions, such as North America and Europe, are attracting manufacturers with growing penetration of plug-in electric vehicles (EVs) and battery electric vehicles (BEVs). However, the Asia Pacific region is giving the lithium-ion battery industry a second wind with favourable governmental policies and profitable sales opportunities in developing Asian countries, such as China and India. The Asia Pacific region (excluding Japan) holds over one-third share of the global market for lithium-ion battery packs and will maintain its position as the fastest-growing market in the upcoming years.

Increasing needs for efficient energy storage systems in a wide range of industrial sectors and burgeoning adoption of EVs in the region will remain the important factors to trigger the market growth. Leading battery manufacturers across the world are jumping on the bandwagon after the sales of BEVs reached new heights in the Asia Pacific region. The rapidly-growing lithium mining activities in Australia are attracting investors to feed to need for lithium in the ever-expanding lithium-ion battery pack market.

Developing countries in the region, including China and India, are the linchpin of Asia’s lithium-ion battery pack market. Being one of the world’s largest automotive markets, China and India are home to the world’s leading battery manufacturers as well as new entrants in the market. Global automakers, such as Suzuki Motor Corporation (SMC) and DENSO Corporation, are investing heavily in the developing markets for lithium-ion battery packs, and it is likely to generate a powerful incentive in the upcoming years. The commanding lead of developing countries in the global lithium-ion battery pack market will only widen with the wave of planned new manufacturing facilities in China and India.

China’s Lead in Lithium-Ion Battery Industry: Reading between the Lines

China is reaching the threshold of a new EV era with its aggressive efforts in boosting e-mobility in the country. With its strict EV policies and the burgeoning number of EVs on the road, China is becoming a success penetrating market for lithium-ion battery pack manufacturers. Leading stakeholders in China’s lithium-ion battery pack market, including manufacturers and investors, are adopting new business strategies to capitalize on the surging domestic as well as global demand.

Taking into consideration the country’s interest in strengthening domestic industries for the future growth of battery-powered EVs, Chinese manufacturers are scaling up the manufacturing of lithium-ion batteries enormously. In June 2018, BYD Co Ltd. – a Chinese manufacturer of rechargeable batteries and battery-powered vehicles – announced that it has opened a new, 24GWh battery factory in Western China's lithium-rich province – Qinghai. The company also announced that it is planning to expand the total production capacity of this facility to 60GWh by 2020.

As the Chinese lithium-ion battery packs market is heavily dependent on lithium imports, the country is increasing its focus on developing the domestic resources to satisfy its burgeoning demand for lithium-ion batteries in the coming future. China is eyeing lithium reserves in Australia and South America, becoming one of the biggest global consumers of lithium. While its focus remains on expanding its domestic lithium output, China is jostling across the lithium-ion battery packs market with significant investments in lithium deals, which is helping the country to tighten its grip on raw material supplies.

Recent developments in the energy storage market in China indicate manufacturers’ efforts to develop and strengthen a business model with its supply chain that concentrates significantly in a single country. By isolating the access to raw materials and establishing strict technical standards, China will soon take a position to set prices of lithium-ion batteries with its aggressive geopolitical influence in the market. Despite the continual efforts made by the United States to fortify its dominance in the lithium-ion battery pack market, China is expected to hold the lead in the market over the next decade.

A New Lease of Life for Lithium-Ion Battery Pack Manufacturers in India

With China as the frontrunner in the manufacturing of BEVs, the lithium-ion battery pack market in the Asia Pacific region has witnessed a quantum leap in the EV era. Meanwhile, India has emerged as a highly lucrative market for lithium-ion battery manufacturers, as the Indian lithium-ion battery pack market valued nearly US$ 8.5 billion in 2018. The country is stepping towards a high-tech e-mobility ecosystem through the medium of changing governmental policies, which is creating profitable opportunities for lithium-ion battery manufacturers in India.

In order to cash in on the EV wave in the country, leading lithium-ion battery pack manufacturers in India are adopting strategies to manufacture batteries locally. A burgeoning number of automakers are investing heavily in India’s EV market and Indian battery manufacturers are gearing up to strengthen their local battery manufacturing ecosystem to meet the future surge in demand for EV batteries. A majority of manufacturers are working closely with research organizations in the country for technology transfer, bolstering research & development activities the Indian market for lithium-ion battery packs.

In June 2018, Munoth Industries Limited (MIL) – a manufacturing company based in Chennai, India – announced that it has invested over US$ 115 million (Rs 799 crores) to set up India’s maiden lithium-ion cell manufacturing unit in the southern state of Andhra Pradesh. The company announced its collaboration with Council for Scientific & Industrial Research (CSIR), which is a Government of India undertaking, and China’s Better Power Company Limited to produce custom size 3.7V pouch lithium-ion cells based on OEM requirements in India.

Amara Raja Batteries Ltd. – another leading lithium-ion battery manufacturer in India, also announced in September 2018 that it is building a lithium-ion battery assembly plant in Andhra Pradesh. The company also declared its collaboration with the Indian Institute of Technology in Chennai and that it aims to supply lithium-ion batteries for e-rickshaws—small privately-owned three-wheeler taxis. The company currently imports lithium-ion cells from LG Chem Ltd., a Korean chemical company, and it aims to end its dependence on foreign imports with its plans to kickstart its own manufacturing unit in the country.

In June 2018, Exide Industries Ltd. – a storage battery producing company in India – announced that it has signed a joint venture with Leclanché SA – a Swiss battery manufacturer – to manufacture lithium-ion battery packs in India. The company also announced that Leclanché will license its technology and its lithium-ion battery manufacturing plant will be based in Gujarat. The company also declared that it will concentrate on providing batteries for electric buses and e-rickshaws.

Multi-million Dollar Government Incentives will Fuel Lithium-ion Battery Production in India

The Government of India recently approved the proposal of ‘Faster Adoption and Manufacturing of Electric Vehicles’ Phase II (FAME Phase II) to encourage electric mobility in the country. The FAME scheme will be implemented during 2019-2022 with a total outlay of US$ 1.45 billion (Rs 10,000 Crores), through which the government is offering incentives to boost local manufacturing of lithium-ion battery packs used in EVs. This is expected to induce a surge in interest to manufacture lithium-ion battery packs locally and lead the country towards the development of the EV ecosystem in the country.

FAME India Phase II is expected to ramp up the EV sales in the country, in turn, providing an impetus to the demand for lithium-ion battery packs. The Indian government’s thrust on e-mobility will boost sales of electric passenger cars, e-buses, and e-rickshaws in the country, which will create a lucrative growth environment for lithium-ion battery pack manufacturers in India.

Some of the other examples of the government initiatives that are shaping the future of India’s lithium-ion battery pack market include,

- An announcement from the Government of India indicates a potential collaboration between LIBCOIN and Bharat Heavy Electricals Limited (BHEL) to form a consortium for the establishment of a 1GWh lithium-ion battery plant in India, which will be scaled up to 30GWh during the course of the project.

- A Memorandum of Agreement was signed between Central Electrochemical Research Institute (CECRI) – a national laboratory under CSIR – and RAASI Solar Power Pvt Ltd – a solar power company – for transfer of technology for RAASI’s lithium-ion battery manufacturing plant in Tamil Nadu.

- In June 2018, Indian Space Research Organisation (ISRO)’s Vikram Sarabhai Space Centre (VSSC) issued a Request for Qualification (RFQ) to transfer its lithium-ion cell manufacturing technology. VSSC aims to commercialize this technology in India’s lithium-ion battery pack market and help lithium-ion battery manufacturers in India to bring down the manufacturing cost to bolster local production of lithium-ion battery packs.

As the world is awakening to the positive business potential in the lithium-ion battery pack market, the competition will only become more intense with time. Manufacturers in the Asia Pacific region will need to slash their production costs and introduce lithium-ion battery packs with innovative and high-tech features to gain an edge. Achieving operational excellence by the virtue of cutting-edge technologies is expected to emerge as a popular trend in Asia’s lithium-ion battery pack market in the foreseeable future.

Aditi Yadwadkar is an experienced market research writer and has written extensively on the Electronics and Semiconductor industry. At Future Market Insights (FMI), she works closely with the Electronics and Semiconductor research team to serve the needs of clients from across the globe. These insights are based on a recent study on Lithium-Ion Battery Pack Market.