Shaped like a spine, new design enables remarkable flexibility, high energy density, and stable voltage no matter how it is flexed or twisted

The trend of Flexible and Wearable electronics is rising rapidly. Smart watches, smart glass, sensors and flexible displays-such as smartphones, tablets, and TVs etc. For this demand for high-performance flexible batteries also increased. Till now, researchers are facing problems to get both flexibility and high energy density in lithium-ion batteries.

Yuan Yang Assistant professor of materials science and engineering in the department of applied physics and mathematics at Columbia Engineering and his team developed a prototype which is able to face these challenges. Yuan Team shaped their flexible battery prototype like the human spine that allows amazing flexibility with high energy density, and also provide stable voltage even it doesn’t matter how it is twisted or flexed.

“The energy density of our prototype is one of the highest reported so far,” says Yang. “We’ve developed a simple and scalable approach to fabricate a flexible spine-like lithium ion battery that has excellent electrochemical and mechanical properties. Our design is a very promising candidate as the first-generation, flexible, commercial lithium-ion battery. We are now optimizing the design and improving its performance.”

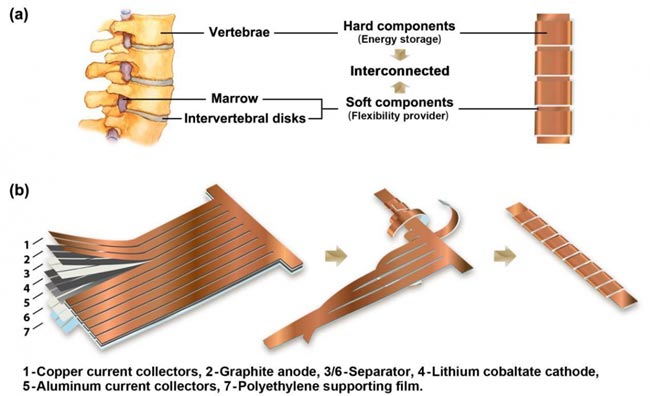

Yuan Team inspired by the supple movement of the spine while doing exercise in the gym. A human spine is highly flexible and mechanically robust. Yuan used the spine model to construct the battery in the same design. The Prototype has a broad and solid segment which is able to store energy by twisting the electrodes around a slim flexible part that connects the electrodes together. As per human spine design the electrodes represents “vertebrae” and flexible part represents "marrow".

“As the volume of the rigid electrode part is significantly larger than the flexible interconnection, the energy density of such a flexible battery can be greater than 85 percent of a battery in standard commercial packaging,” Yang explains. “Because of the high proportion of the active materials in the whole structure, our spine-like battery shows very high energy density—higher than any other reports we are aware of. The battery also successfully survived a harsh dynamic mechanical load test because of our rational bio-inspired design.”

Yuan’s team separated the anode/separator/cathode/separator into long strips with multiple “branches” extending out 90 degrees from the “backbone”. Then they enfold each branch around the backbone to form thick stacks for storing energy, like vertebrae in a spine. Due to having this unique design, the battery’s energy density is limited only by the longitudinal percentage of vertebra-like stacks compared to the whole length of the device, which can easily reach over 90 percent.

Testing the prototype by cycling, they found stable voltage outline, confirmed the mechanical stability of their prototype. They also flexed and twisted it even after discharge but the design is perfect that it didn’t affect the voltage outline. The testing is performed by putting the battery with higher current density and capacity retention is also high (84 percent at 3C, the charge in 1/3 of an hour). The prototype also passed the dynamic mechanical load test.

“Our spine-like design is much more mechanically robust than are conventional designs,” Yang says. “We anticipate that our bio-inspired, scalable method to fabricate flexible Li-ion batteries could greatly advance the commercialization of flexible devices.”