The global and Indian electronics industry is now progressing at a rapid speed backed by billions of investments, imperative policies and also due to invention of innovative technologies, tools, and machineries. In India alone, the growth of the industry was projected to Rs 4.58 Lakh crore for the FY 2018-19, but it represented only 3.3 percent share in the international market. According to various experts, this marginal share is mostly due to lack of awareness of several policies, incentives, and most importantly, lack of sophisticated technology and cutting-edge machineries. In order to boost growth and make India globally competitive in electronics manufacturing, the country must implement top-notch technology along with latest equipment. In this regard, we spoke to Rajoo Goel, secretary general, Electronic Industries Association of India (ELCINA) about the various challenges of Indian electronics manufacturing service (EMS) cluster, the current technologies implemented, and why the growth of manufacturing is also related to acquiring state-of-the-art technology and latest equipment.

Q. Why ELCINA was formed and what is its current mission and vision?

The association was formed in 1967 by seven component manufacturers in Mumbai when the electronics industry was struggling to deal with several complicated policy issues, which required to be rectified. From the beginning, our main vision was to expand the electronics manufacturing cluster in the country and our focus was always on strong growth of electronics components and on value added manufacturing. Now, we shifted our focus to help build strong technology and equipment to boost the sector. In the last fifteen years, our focus has been shifted more on EMS sector, raw materials, and equipment manufacturing. Our basic intention is to promote the industry which during the late 60s was a fledgling industry. There is now a growth in the demand for components and electronics equipment.

Q. Currently, what are the various challenges of EMS sector and what are your key strategies to solve them?

By nature, the EMS segment is extremely competitive. They are now growing because a very high share in the manufacturing and production is now catered through the EMS companies, which work on low margins around 5-7 percent. One big challenge is that they have to import all their inputs and all their components. To prevent that we have to strengthen our own component sector and we need to ensure that the supply of component for EMS companies should be regular. Right now, there is a huge issue with the semiconductor devices, which is not available. We have to take tough decisions, invest, and take risks. The country still lacks global-sized EMS companies.

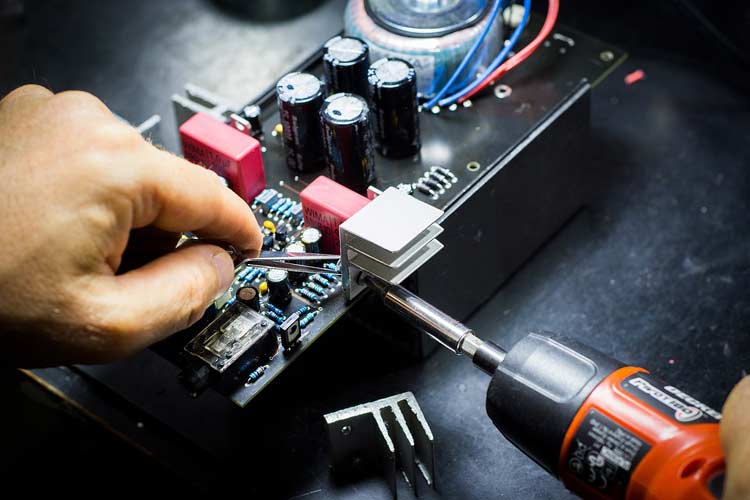

Electronics Manufacturing- Source: Pixabay

Q. Where does technology enhancement in India’s electronics manufacturing stand in the country?

Initially, our primary focus was mostly on value addition because if it is not strong then the country cannot develop any local technology. If a country constantly keeps on importing all its components and raw materials, it cannot develop the core technology, which is required for electronics manufacturing. Currently, a lot of cutting-edge technology are already happening in the country because we are doing a lot in semiconductor design and also, we are doing a lot of innovation in these areas. So, I think we are moving ahead but the problem we face is we don’t have so much funding for R&D for technology development. In fact, the revised National Policy on Electronics (NPE) 2019 focused more on developing latest technology for which investments are already happening. The Ministry of Electronics and Information Technology (MeitY) is closely working with various organizations to develop e-waste management technology, recycle and reduce. But we have to produce more semiconductors in the country.

Q. How technology playing a key role in India’s electronics manufacturing and where is the difference when compared to China, Vietnam, and other European countries?

When compared with Vietnam, India is not far behind technology, but China is now far ahead because it started manufacturing very early. With extreme aggression China expanded its industry, which helped it become the world’s largest exporter of electronics. It has developed its own ecosystem and has got very large specialized industrial parks. In facts, its semiconductor industry is also becoming globally competitive like Japan, Korea, and USA. Although electronics manufacturing in India started long back, the nation failed to develop its high-added value ecosystem. It is not that India does not understand technology, our scientists and technologists are very sharp and they are doing a great job. The problem is India did not develop a healthy ecosystem and in the entire 90s we failed to keep pace with global industry in terms of technology.

Q. What kind of new technologies and machineries required to make this sector globally competitive?

For a sophisticated electronics manufacturing, PCB assembly, and manufacturing of components, a very wide spectrum of equipment and technology is required. A lot of new equipment is required for mechanical processing because there are many metal and plastic components where its molding is also required through wires. The high-tech equipment, which is now used in large numbers relate to PCB assembly and SMT equipment. These machines are not made in India and they are all driven by computers, and extremely precise because they can mount thousands of small components on PCB. We need to manufacture all these machines in India if we have to strengthen our own industry. Even there are specialized equipment required for PCB manufacturing. You need specialized equipment for specializing the film which is used in a capacitor for making ceramics resistor. It is a bit of a chicken and egg situation because once the industry grows, the demand for this equipment will grow. The global manufacturers now are not keen to come to India and develop them and we have to convince them that India is a potential market.

Smart Electronics Manufacturing- Source- Pixabay

Q. What is the role of robotics, AI, and IoT in current electronics manufacturing in the country? What is its potential in the coming years?

If you particularly look at robotics that can perform different works at the same time, it will have some severe impact on employment potential in India. The other angle is the cost aspect because the equipment driven by robotics technologies are going to be more expensive, and it requires specialized maintenance. In India, it is not going to be popular even in the coming ten years. There is now selective employment of such equipment. If you have very high precision equipment driven by robotics it will give you more output. Most of the current equipment used by the EMS and semiconductor industry are not very high-level electronics and it is mostly of software related than hardware. Secondly, if you look at IoT, it is a different subject. It is driven a lot on transmitter, sensors, receivers etc. It’s going to create more of wireless technology via hand-held device and is used in smart cities and industry 4.0. We are going to have a world, which is going to be connected wirelessly at a very high-speed coupled with AI and IoT. We need to invest more in these areas.