A major hurdle, that stands in the way of boosting the growth of electric vehicles is the time taken for charging the batteries, and the number of charging stations available. This is also posing a huge threat to the growth of the overall global electric vehicle (EV) market. One solution for the same is wireless charging on roads which is getting developed very rapidly in the US and several European countries. Wireless charging is nothing but an improved version of smartphone charging coupled with numerous differences. It helps an electric car to charge devoid of any kind of cables. But the point to be noted is that as the power goes up or the momentum increases, a number of imperative things need to be taken care of such as thermal loss management. The more the power and higher the efficiency, the more there are losses of heat, and something must be done to manage that heat. In this regard, we spoke to Mauricio Esguerra, CEO & Co-founder, Magment - a Munich-based global provider of cutting-edge wireless charging solutions for EVs. Esguerra highlighted the current challenges of the global EV sector, the solutions, and how Magment's solution can be a game-changer for the sector.

Q. Throughout the world, charging vehicles is a huge concern among consumers which is also pressurizing the global growth of EVs. Would you like to highlight some particular initiatives and technology that could strengthen the global EV chain?

Magment’s technology is a key enabler for EV adoption. Our dynamic wireless charging technology based on proprietary magnetizable concrete supports the push for global EV adoption by solving one of the major problems that is practical economic charging infrastructure with no limitations for widespread adoption. An area of special interest for us is Intralogistics, where our focus is industrial floor electrification that allows for dynamic wireless charging of AMRs, automatic guided vehicles (AGVs), and larger equipment including forklifts, eliminating downtime required for static charging and therefore reducing equipment needs.

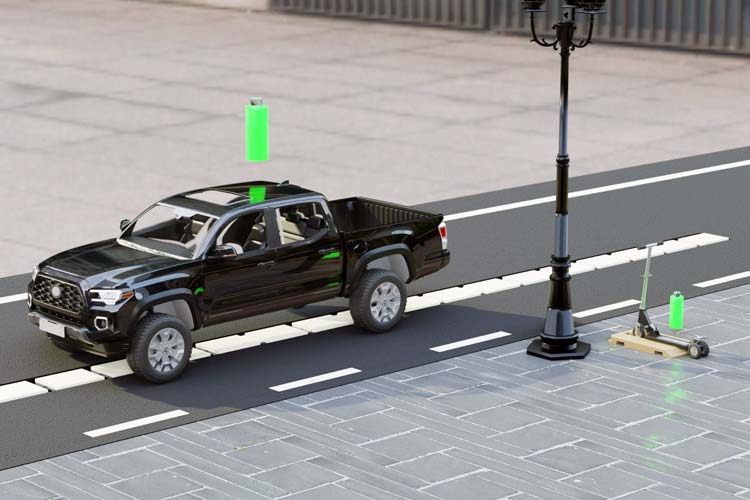

The future of wireless charging will be for roadways’ electrification where dynamic charging allows for any vehicle to charge while traveling and can significantly reduce or even eliminate charging breaks. This technology, under development, is made possible using magnetizable concrete that not only is long-lasting but has high strength and is virtually maintenance-free. Dynamic wireless charging can also reduce the need for batteries while eliminating range anxiety. Patented magnetizable concrete in combination with proprietary winding and casting technologies are enabling the production of robust wireless charging pads that can be produced locally.

Source: Magment

Q. What are the various challenges currently this sector is witnessing? Can you point out some of the appropriate solutions that could solve these challenges?

There are two main challenges. The first one is charging infrastructure for electric vehicles. Intralogistics vehicles (forklifts, AGVs, AMRs) as well as EVs have substantial charging downtime and require cables and in many instances, manual connection for plug-in charging. Our dynamic wireless charging solution reduces or fully eliminates charging breaks with floor integrated dynamic wireless charging for forklifts and other intralogistics vehicles along with roads in the near future. We are currently working on pilot projects in the USA, Germany, and have applied for funding for a similar one in Spain. Besides eliminating the need to stop charging, our technology enables the reduction of battery sizes and therefore EV cost.

The second challenge involves the vehicles. At present, no vehicles are equipped from the factory to be wirelessly charged. There is a single standard for wireless charging and at present, there is a standard for static charging at a power level of up to 11 kW (for smaller BEVs). Our designs are made to be compliant with the standards and we participate in the committees that are developing them for different power levels and dynamic charging. The fact that there is a single standard will facilitate wider adoption, but there is the chicken and egg problem. Without vehicles that can charge wirelessly, there is no investment in infrastructure and vice versa.

Q. When you speak of electric vehicles, the major concern among buyers and researchers is of battery or a charging station. Do Consumers still worry about charging stations?

As mentioned earlier, our technology can practically eliminate range anxiety if implemented strategically. Charging while in operation is not only a very good option for reducing charging needs and battery sizes, but can serve for emergency charging and has the additional benefit of distributing the energy supply when compared to large high-demand charging stations which would be required along highways for charging multiple trucks, with very large batteries, simultaneously.

The other area where we have developed products is in micromobility with our MagDock, which is an intelligent static wireless charging docking station with a concrete housing. The transmitter design is based on patented Magment magnetizable concrete and coil technology which enables wide alignment tolerance and ample enough vertical transmission distance. It is interoperable with any e-scooter form factor. Magment also offers wireless upgrade kits for scooters that can also be adapted to be used with other types of micro-mobility vehicles such as e-mopeds, e-bikes, cargo bikes, tricycles, AMRs as well as delivery or disinfection robots.

Source: Magment

Q. What are some of the latest technologies you are deploying on your EV charging stations? Kindly elucidate them.

We clearly see dynamic wireless charging enabled by wireless power transfer pads made of magnetizable concrete as the future. The business cases, developed together with our customers, clearly show mutual financial benefit of all parties in the process of industrial floor electrification as well as road electrification. Reducing battery sizes and waiting time brings huge benefits for the electric vehicles industry and the reduction of GHG emissions.

Q. Coming to your company, what are the business models of Magment? How far has it changed since the pandemic? How unique is Magment from other companies in terms of providing solutions for EVs?

Magment is a fabless company with strong relationships with production and development partners. We have a strong IP portfolio and sell wireless charging infrastructure directly or through partners. The Pandemic has affected everyone and Magment is not the exception. Our funding and projects have been delayed but we have an experienced team of engineers and marketers, which are leading the company in the right direction even throughout these challenging times with Covid.

One of the key aspects that differentiate Magment and helps to stay ahead of the competition is our proprietary magnetizable concrete which enables scalability of production, robust wireless power transmission, and lower costs. Our technology uses traditional construction techniques and widely available raw materials which include cement and ferrites that are mainly recycled from e-waste streams. Our highly specialized team and strong IP that includes advanced winding technology and magnetic design enable high-efficiency wireless power transmission which is an asset that can give us certain advantages over our competition, but one of the most important strengths is our cooperation with world-leading players in the cement industry.

Q. Which are the countries you think are leading the EV charging stations and which are the countries you are looking to strengthen your foothold?

Undoubtedly China and the EU are leading the way in the adoption of EVs, followed by the US and other industrialized countries. This overview of the electric vehicles market can provide us with an answer. Charging infrastructure must be pulled by electric vehicle needs. If there are no electric vehicles, there is no need for charging infrastructure. On the other hand, for the industrial floor electrification market (intralogistics) the business case is much clearer, given the high level of electrification of logistics-type vehicles in industrialized nations.

Q. What are your roadmaps in the coming few years?

This year we plan to build several real-life industrial floor applications and in the next few years, we are expected to demonstrate the feasibility and implement highway electrification of roadways. Our MagPad, the world's first electric scooter wireless charging station is already in the market.