Right temperature control during the storage and transport of vaccines is critical to ensure their potency and safety. Even though more and more development is made in this regard to ensure safe transport and storage facilities, there are still weak points that lead to a reduction in the potency of vaccines. When a vaccine is damaged by freezing, the potency lost can never be restored and the damage is permanent.

The Blackfrog Technologies did research and looked out for the possible solutions thereby taking a step forward and working towards developing a portable active cooling device. The team assures that the device will provide a platform for delivery of vaccines and all other biological parts like blood, tissue, culture which require to be kept strictly between 2 and 8 degrees Celsius for 8 hours. Besides, it will provide refrigeration and 100 percent accountability in terms of assured temperature maintenance.

Excited to know more about the product, the team, and their future plans, the team CircuitDigest had a detailed conversation with the co-founder and CTO of the company - Ashlesh Bhat. Ashlesh has done a master's in telecommunication and management from Barcelona Tech and a bachelor's in Electronics and communication from MIT Manipal. He leads the electronics design efforts at Blackfrog Technologies.

Q. What is BlackFrog all about? And how did you come up with this interesting name “BlackFrog”?

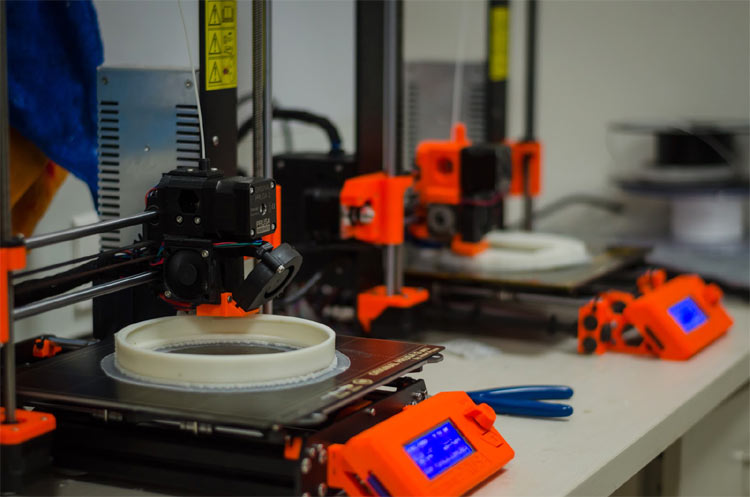

Blackfrog initially started as a product design service company. We started as an engineering consultancy firm to provide prototyping solutions for academic requirements. The team has now pivoted to a single product that is a portable bio-medical refrigerator that can be used for the transportation of thermally-sensitive biological samples.

Regarding the name - ‘Blackfrog’ is the common name for a microhylid frog called ‘Melanobatrachus Indicus’. This frog is endemic to the Western Ghats, where we are based out of. The frog is known for its survival skills and we named the company ‘Blackfrog’ as a tribute to the endangered species.

Q. We see you got affiliation from the Department of Bio-Technology. Tell us something about this.

This project started when we received the BIG (Biotechnology Ignition Grant) from DBT-BIRAC to develop the proof of concept for such a device like ours. After which we received the seed funds through them to take the project further. Their interest in us has always been in a public health context. Immunization is one of the most successful and cost-effective health interventions and prevents between two and three million deaths every year. Immunization protects against diseases such as diphtheria, measles, pertussis (whooping cough), pneumonia, polio, rotavirus diarrhea, rubella, and tetanus. The benefits of immunization are increasingly being extended from children to adolescents and adults, protecting against life-threatening diseases such as influenza, meningitis, and cancers (cervical and liver cancers).

However, even now, around 22 million infants are not fully immunized with routine vaccines and more than 1.5 million children under five die from diseases that could be prevented by existing vaccines.

The percentage of infants worldwide being fully vaccinated with the diphtheria-tetanus-pertussis vaccine is holding steady: An estimated 83% in 2011, compared with 83% in 2009 and 84% in 2010.

While this is commendable, further efforts are needed to ensure that people all over the world are protected from vaccine-preventable diseases. More than half of all incompletely vaccinated children live in one of three countries: India (32% of incompletely vaccinated children), Nigeria (14%), and Indonesia (7%).

Q. Tell us about your team and office set-up.

We are a team of 10 members, out of which most of us are engineers. The founding team included Mayur Shetty Chief Executive officer, Donson D Souza, Operations and Ashlesh Bhat, Chief Technical Officer.

Q. Tell us about your product Emvolio and what were the challenges that you faced in developing it?

We are developing Emvolio, a portable active cooling (battery-powered) device that will provide a platform for delivery of vaccines and all other biological parts like blood, tissue, culture which require to be kept strictly between 2 and 8 degrees Celsius for 8 hours. The device provides refrigeration as well as 100 percent accountability in terms of assured temperature maintenance; hence seeking to replace standard ice-boxes and other cruder forms like thermos flasks.

Q. How does your supply chain work? From where and how do your source components for your projects and prototypes?

We have two types of vendors - One is for critical components of the device and others for the rest. For critical components, there is a set of standards our vendors need to meet. Most of our vendors for electronic components and PCB manufacturing are from China. Mechanical components vendors are usually from both India and China. There are strict internal IQC protocols set to make sure every lot of goods received is up to the mark.

Q. We would like you to share some details on ‘Sanjivani’ which is the portable active (battery-powered) cooling device created by your company.

We have designed and successfully tested a prototype for a portable device for the transport of biological substances. WHO addressed this problem 20 years ago and multiple projects and teams have tried to explore the principle of solid-state cooling as a solution to refrigeration due to their compact nature, lack of moving parts and low-weight. However, extremely low power efficiency and insulation issues have rendered the attempts unsuccessful. We have overcome this problem with a novel design by constraining the cooling chamber to precisely the requirement of a daily-delivery of vaccines and a dispatch mechanism of the vials that prevents repeated freeze-thaw cycles. Our design is optimized to ensure a batch of vaccines can be cooled for 8-12 hours with just 20 mAh batteries i.e. the equivalent of a commercial cellphone power-bank. The device works on 12V source; so in the event of emergency power-loss, it can be directly plugged onto a motorcycle/car/auto-rickshaw system with an adapter, we provide. Besides, the device can be charged with an external solar-panel too.

Q. Tell us about your first paying customer and how Black frog has evolved from there?

Our first customer was the SELCO foundation that asked for our device around 6 months back. With their feedback, we have been able to refine our technology a lot. They have been using this device at Swami Vivekananda Youth Movement (SVYM) hospital in Sargur in the ambulance to treat Jenu-Kuruba tribal groups.

Q. What are the future plans for Blackfrog in terms of growth and revenue?

By the end of 2020, we will be done with our industrial design of the device to make it mass-producible. We plan to set up an assembly plant here in Manipal to assemble the final devices. We aim to scale to 1000 devices produced in 2021. For manufacturing and sales, we will have to scale for 10 on payroll to up 20 in 2021.

Q. What does your device provide comparing with the current technology in use?

9 out of the 15 vaccines commonly administered today are freeze-sensitive. And they need to be strictly maintained between 2 and 8 degrees Celsius. However, the cold-boxes (ice/gel-pack based) do not provide assured temperature control. When we tested iceboxes at an ambient temperature of 25 degrees C, the temperature inside the box was never between 2 and 8 degrees C for a 48 hours test-period (there are various publications to support this and similar results). We at Blackfrog, assure 100% precise temperature control that can be set at any temperature for the stable cooling platform during transport. An electronic feedback mechanism is used to ensure the temperature conditions of the containments are never compromised. We are currently in the process of validating our system against the ice-boxes in the field; so far we have got very promising results.

Q. How do you plan your pricing strategy?

Ice-boxes are sold all over the world for its simplicity and low-cost. However, if we take into account the need for refrigerators that are required to freeze the ice-packs to -20 degrees Celsius before they go in the box and the potency loss (and thus an economic burden) associated with this practice, it is well justified to invest in a slightly more expensive technology to replace it. We are currently working out the precise figures as to what the losses in vaccines translate to in terms of monetary value. This will provide us with not only a good pricing strategy, but also the overall picture of the market. Our team is working to put this down to paper. Besides this, we are in the process of getting a letter-of-interest from Medical universities that require cold-chain management for their research. We plan to sell our device to them in individual units or as a rental service.

Q. What are your sales channels?

Our sales channel includes retail sales for laboratories and testing facilities, supported by our small batch-production plant, procurement in bulk by WHO (requires WHO PQS certification and complicated purchase filters) and Hyperlocal logistics. Currently, labs across the country use third party courier services for the transport of thermally sensitive biological substances and they quote extremely high prices for the service. They use cooled gel-packs, which have the same aforementioned problems (for example, over-freezing). We are setting up a similar logistics venture to transport samples. Since our device works on 12V DC, we are now retrofitting it onto the back-seat of a motorcycle and powering it with the engine's alternator. This is just in the implementation stage currently and we are in talks with a few labs to finalize details. We have promised to provide the entire data-log with temperature charts for the process to ensure accountability at all times. Since our device is actively cooled with a feedback mechanism and we are confident with its working, we have promised to provide insurance for the samples we are transporting if they fall out of the 2-8 Degree range. Apart from the small revenue, this will help us with our product testing too.

Moreover, there are beneficiaries that are the organizations (governmental and NGOs) that seek to bring accountability in the vaccines being administered and biological samples that are transported. Besides easing the economic burden associated with this, our solution helps with the difficult and tedious process of disposing of unviable vaccines, repeated testing (lumbar puncture, blood-drawing) from loss of samples.