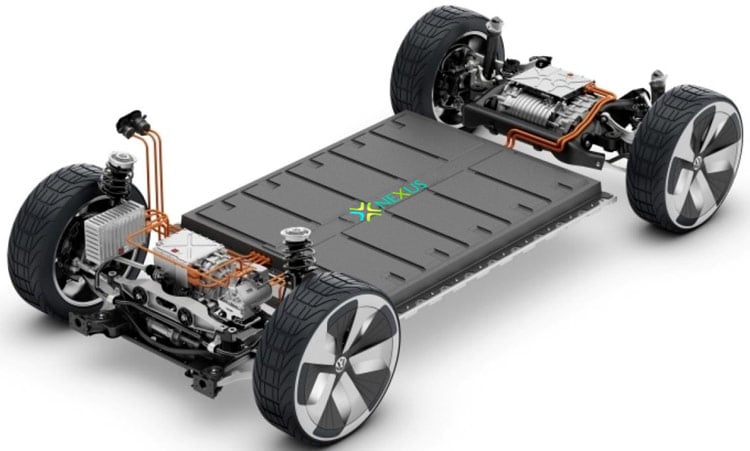

With Electric Vehicles gaining immense popularity, lithium-ion batteries too are witnessing a surge in sales, but do you know there are quite a few limitations of lithium-ion batteries and they can prove hazardous for the environment? Yes, you heard that right. Understanding the issues with the most hyped lithium-ion batteries and finding the alternative to these, Bhubaneswar-based twin sisters, Nikita and Nishita co-founded a startup, Nexus Power in 2019. The company is working on an alternative to a green energy battery solution. The duo has come up with the idea of manufacturing a completely organic battery using a biodegradable material. Curious to know what the company does, we had a conversation with Ms. Nikita Baliarsingh, who is the co-founder and the COO of the company.

Q. Tell us about Nexus power. Why do you think an alternative solution is required for electric vehicles?

The first thing that we came across when we were thinking about startups and the ecosystem in India, we realized that electric vehicles are not popular in the market. Though we have a lot of offerings, people are not buying them, and that’s because there are a few things that the Indian consumer finds difficult to adjust with. And major of these concerns are related to the battery because the lithium-ion batteries take a long time to charge, they're hazardous to the environment, in fact, they're toxic. It's difficult to procure them as well. So, you have to import it from different places and assemble it here in India.

What we thought was why not have something that you can generate or build from the country itself, because there is so much material available here. If any of them can be a good substitute for lithium, why not try and work on that and make batteries from that. That is how we began this entire research to try and find out an alternate material that is abundantly available in India.

Probably through a few books and a few research papers, we found out that there is a material, in fact not a material but nutrients (proteins) that are there in living organisms, which does almost a similar kind of a function of electron transfer. We tried to use that artificially with the process called bio-mimicry. We wanted to use it in batteries and see if it works. We were lucky because it turned out to be a very efficient substitute for lithium. That's how we began this entire journey, and then we stumbled upon crop residue as a source to extract these proteins.

The reason why we decided to go into alternate material was actually that India was not producing lithium-ion batteries, they were being assembled here. We thought we need something which we can make in India, not just assemble but manufacture. Besides, we wanted an eco-friendly alternative because lithium is not an environmentally-friendly option.

Q. The batteries from Nexus have bio-degradable electrodes and electrolytes; can you tell us more about how your battery chemistry works?

As I mentioned, we use an element called proteins, different protein structures, and different chemical bonds because proteins are the natural element present in living organisms and are available in abundance. So, this is automatically biodegradable, which is not hazardous to the environment. We make three structural elements, which is the electrodes like cathode, anode, and the electrolyte using these proteins. Multiple kinds of proteins go into the entire chemistry and that's how the entire cell is made and that is the reason why it is also biodegradable.

Q. Apart from being bio-degradable, what other advantages do Nexus batteries have? How does it differ from conventional batteries?

There are certain advantages that we have found so far. We don't want to claim any numbers right now because it's subject to a lot of licensing and certifications. But to give you a little brief, they are of course non-hazardous at all. It's cheaper than lithium batteries because the sourcing of raw material is cheap and the entire processing happens in India itself. So, there is no import-export duty involved. The entire battery eventually gets cheaper. Apart from that, there is one interesting thing that we found which we were not looking at in the beginning. We found that the proteins are very efficient at electron transfer. Also, the charge time that a battery should take drastically reduces. So, if you say, the lithium-ion battery takes about 4-5 hours to attain full charge, the Nexus batteries might just be able to achieve that in say 40-45 minutes, which is quite a lesser time as compared to lithium-ion batteries. We are still in the R&D and still want to shorten this charging time. We want to maybe wrap up a full charge in say 10 to 15 minutes, or something, which is as quick as refueling your car at a petrol station maybe. We are trying to achieve that efficiency of the battery, but it already shows us promising results.

Along with this, proteins also tend to be sticky with each other. So, they bond very well. When they bond very well and close, they give you a longer range as well. Probably, if you could drive a two-wheeler EV for 65 or 70 kilometers, this battery could give you a range of 100+ kilometers in one charge. And it has been showing us promising results. We are being hopeful to go ahead to the longer range also. But of course, these numbers will only come into the picture once we've licensed the entire product and certified by certain agencies of the government, then only we will claim all the numbers.

Q. Apart from these advantages, the batteries from Nexus Power are comparatively less in weight, because you're using biodegradable material, which will be light in weight as compared to the existing solution. Please shed some light on this.

It's not exactly light in weight. The energy density is a different material that we are using. So, overall, the battery is not light, it's probably at par lithium-ion batteries. It's almost the same weight, though we've not done this comparison of the entire battery pack and how it weighs in comparison to lithium-ion batteries. But it doesn't matter much with the weight. It's with the energy density, the power density that the battery carries, which is a little higher as compared to lithium-ion batteries.

The material is used for electron transfer, that's the basic purpose of proteins. So they do it efficiently wherever you put them, that is what matters. But, of course, the batteries can be made in various sizes because we're using nano-materials and we are going down into the basic cell chemistry. The battery that we make can be made in different sizes and structures, depending upon the industry standards. But I don't think it's anything to do with the weight of the cell of the entire battery. It's going to be as heavy as lithium-ion batteries.

Q. What are some of the technical challenges that you are currently facing and how are planning to overcome them?

When we started, we were not sure of a lot of things in this domain. It was just a very vague idea to start researching and start reading about it. But me and my co-founder Nishita, neither of us are engineering graduates. So, that was another challenge, we had to first understand the basic units of all of these and then try and work on them. So, we did take up a few courses online, a few certificate programs from Institutes like IIT to understand the entire domain. And then we plunged into it. We used to read through research papers and try and understand as much as we could. So, there was not much of a technical challenge, it was more of a reading thing. The more knowledge we gained, the better we got at it. That's how it was!

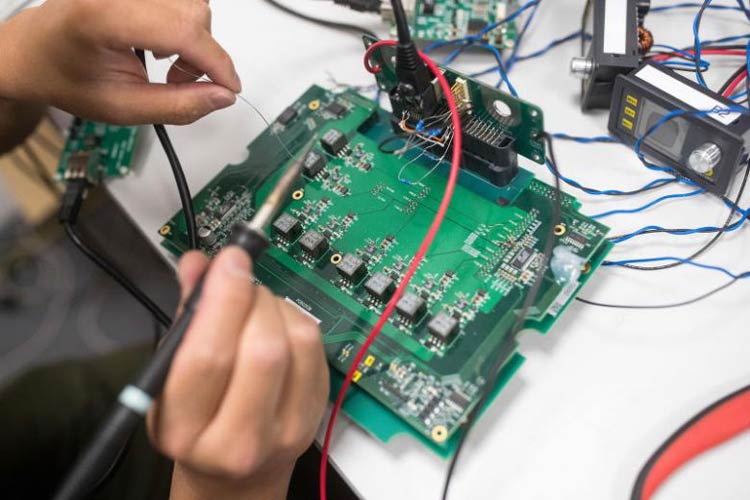

Because we were very passionate about the electric vehicles and components of electric vehicles, it was nothing that we thought is stopping us from going ahead with this entire plan, and we were quite excited to work on it. So, we didn't feel that we might be technically handicapped, or there might be a problem that we might face. We just kept going with the flow. And we kept enjoying what we were trying to experiment with. We made our prototype at home during the lockdown in 2020. Once that was ready, the confidence level that we had gone higher than what we had at the beginning of this entire project. Eventually, we had a team on board and people started joining us and things started changing. So, right now it's quite stable, quite comfortable for us. Nothing was challenging in terms of technology, but yes, few things do come your way which you have to deal with anyhow.

Q. Can you elaborate a bit on the prototype built by Nexus Power? What exactly does it do?

It's a crude form prototype; it does not have the BMS (battery management system) yet. We’re still working on the R&D of the efficiency. But we did make a 48 volt, 36 amp variant. 48 volt is one which we use in two-wheeler electric vehicles. Based on that specification, we made a crude form prototype and we tested that in a two-wheeler. We tested its ability to power the two-wheeler vehicle and charge and retention rate and mechanical stability, etc. So, these tests are still going on, and the results are very promising. That's why we are going ahead with the entire project; we are still doing the R&D. So, we're looking forward to probably get into proper market tests sometimes in 2022 and then go commercial by the later half that year hopefully if the lockdowns and other restrictions don't come into the picture, we'll be able to achieve our timelines.

Q. How much have you progressed with the idea? What tests and validations have been performed?

Ideally, we have made one battery-pack prototype (crude form prototype) which efficiently proves that this battery can power the electric vehicle; it has the mechanical stability to be used on vehicles for daily commute. And it also charges a little faster as compared to lithium-ion batteries. We are conducting tests to find out the lifecycle, the strength of the battery, how many charge cycles can it handle before it would start degrading, etc. These are the basic tests that we keep doing every day because every day we come up with new material because there are various types of proteins. Every protein can give you a different result, and that's how the entire research is going on. So every day, we come up with new material; we try and test that, if it works, we go ahead, otherwise we discontinue and go ahead with other material.

Q. How do you see the roadmap ahead? When do you plan to bring the product to the market and how are you planning to take it to the market?

We plan to bring it to the market around the fourth quarter of 2022, which is about a year and a half from now. So ideally, we want to start with doing a lot of market tests. We would like to have tie-ups with a few OEMs. So, we want to conduct initial market tests and then larger pilot programs to make sure that the batteries are real good efficiency of suited lithium-ion batteries. Once we are done with all of those, we would want to go commercial. And when we get into the commercial launch of the batteries, we will look at having a lot of brand tie-ups. There are a lot of brands already manufacturing electric vehicles, two-wheelers vehicles, and three-wheeler vehicles. So, we want to have a tie-up with them and want them to have our batteries put into their vehicles. We're looking at a B2B model and we look at tying up with quite efficient and quite well-known brands. Hopefully, we will be able to manage that.

Q. Your prototype is for a two-wheeler, so can we assume that Nexus powers first targeting the two-wheeler market before getting into the formula? What are your plans?

Yes, most likely, we are targeting the two-wheeler and three-wheeler market at the same time, because the configuration of the battery for these two segments is very similar. Looking at the market, they already exist. So we have two-wheelers and three-wheeler electric vehicles already in the market. So, it's easier to do the market tests. And it's also more than convenient to step into the market with these variants. Compared to four-wheelers, there's still a long time to go for them to be a household commodity for a four-wheeler to be a fully electric vehicle. So there's still a long way to go. And the battery configuration, the specifications are slightly different as compared to two-wheeler or three-wheeler vehicles. So, I think we first want to cater to the two-wheeler and three-wheeler segments and be sure of the product. And then reach out to the four-wheeler side and try and do the R&D on that side.

In the end, Nikita added that entrepreneurship isn’t something that requires a lot of money to start with or that you need to have a very good team to start. What’s most important in this entire space is that as a founder you have to be emotionally very stable. You need to have your grounds and you should be very stable. Besides, you don't have to be affected much with any highs and lows. So, it's good to be cool and calm in all situations. You have to come and take every day as it comes to you. And you cannot be very highly ambitious or you can't be very humble with your product as well. So, you just have to maintain a balance, and probably that is going to help in going forward.