Global warming is increasing day by day and is expected to have a far-reaching, long-lasting, devastating effect on planet Earth. To combat the situation, various companies are doing their bit. Aerostrovilos Energy, the IIT-Madras incubated automotive start-up joined the bandwagon in 2017 with the idea to develop gas turbines that are primarily used for aerospace propulsion or large power generation from tens to hundreds of MWs. Gas turbines are the cleanest burning devices that can adapt to a variety of fuels, thereby creating a net Carbon Neutral ecosystem with the help of biofuels.

Curious to know about the company and how effective their solutions are in lowering down the impact on the environment, we sat down with Rohit Grover, Co-founder, and CEO of Aerostrovilos Energy. While pursuing Bachelor and Master in Aerospace Engineering, Rohit got keenly interested in the technology and understood that there is a huge gap in developing jet engine technology in India. He wanted to pioneer it and work towards bringing about change in jet engine technology.

Taking out time from his busy schedule, Rohit shared the idea behind starting the company, work style, success story of Aerostrovilos Energy, and lots more with the CircuitDigest team.

Q. ‘Aerostrovilos Energy’ is known for manufacturing India’s first indigenous gas turbine for power generation. How was your journey in getting this done?

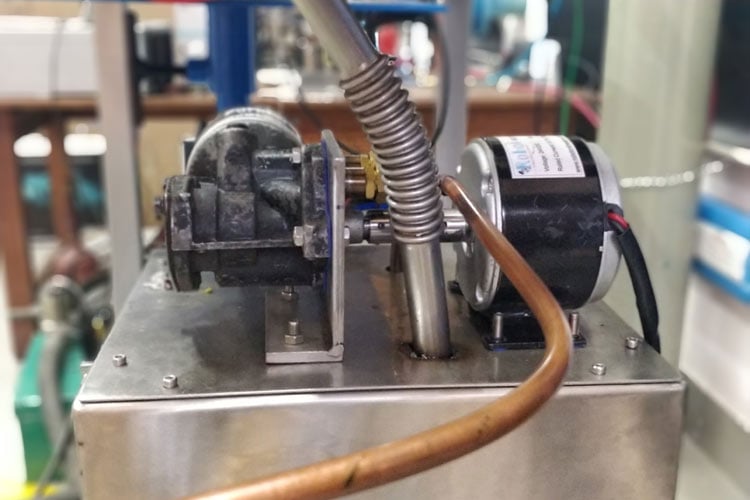

We started this company in 2017 with a small team of three guys and have now expanded to a multi-disciplinary team of 10 members right now with many of them from IIT Madras and other IITs as well. We are grateful for the immense support that we have received from IIT Madras labs, namely the NCCRD which is the biggest research center in the world for such technology. We have also been fortunate to be able to get incubated at IIT Madras incubation cell, ranked the best in the country for its deep tech startups. We initially started with the development of a 20kW machine which revolved around buying some of the components and testing our existing IP components. Going forward, we have gone into complete indigenous development of a 100kW system from scratch.

Q. Please shed some light on grants that Aerostrovilos Energy has got. How helpful did IITM prove to be?

We have been fortunate to receive financial support as a grant from Bharat Petroleum as part of their Project Ankur for our product development. We have also been able to adopt the technology from the NCCRD lab on Gas Turbine Combustion that makes our system far better than any existing turbine technologies. Besides, we are grateful to get support from the Incubation cell for funding, investor connections, mentors, and other legal and CS facilities.

Q. Tell us something about LX-101, the 100kW micro gas turbine generator. What are the main applications of these turbines?

Today, the Micro Turbines for 100kW power level are used in off-grid continuous power operations such as oil rigs, decentralized power, industrial co-generation. These applications typically have an unreliable grid which makes turbines that are extremely reliable as a perfect solution. It has extremely low operation and maintenance requirements. However, due to extremely high capital cost, typically 10 times of a diesel gen-set, it has not been used as a backup power but only as prime power, hence has a very small market share. In the early 2010s when the battery costs were high; the turbine generators were tried as a range extender by many companies and didn’t move to a production scale due to high costing. Now with our innovation, we are able to bring the material requirement down to the less exotic and automotive category and thereby bringing the cost down at par with the existing Diesel Engine technology. This can now allow it to find applications in the Diesel gen-set and EV market.

Q. How do these Fuels Flexible Micro Gas Turbines (MGT) work? What is its significance?

The Micro Gas Turbines are similar to the Jet Engine technology that powers an aircraft or big Gas Turbine-based power plants that power our cities. These are a miniaturized version of the same. Whereas the bigger can run up from a few Megawatts to 100s of Megawatts, but the micro turbine is from 20-200 Kilowatt range.

The core technology is the same that uses the Brayton cycle where the incoming air is compressed to higher pressure, burnt in a combustion chamber, and expanded across a turbine to create the shaft power that can be used to run a generator. Unlike bigger turbines, the microturbines can be completely oil-free. Micro Turbines in principle are fuel flexible which requires some modification to a combustion chamber for different fuels. However, with our unique combustion chamber technology, we don’t need to do that either. For liquid or gaseous fuel, a small change in the fuel line is needed to select the fuel and the same machine can be run with different variety of fuels starting from CNG, LPG, diesel, petrol, biogas, biodiesel, etc.

Turbines, unlike DG sets, burn the fuel completely like an LPG burner in our kitchen stoves and has very little pollutant emissions. The emission levels are 20-30 times lower than the most stringent BSVI as well. They are 5 times smaller in size and 8 times lighter than a diesel engine for the same power level.

Q. How can Micro Gas Turbines (MGT) be used in Automobiles? What advantages does it have over IC Engines and EVs?

Micro Gas Turbines have previously been tried before in the vehicle but were mechanically coupled to the powertrain for propelling the vehicle. However, in the current case, they will be producing electric power and will be used to power the electric motor of an EV. This is similar to a series hybrid EV where we have an on-board generator, which in this case will be a turbine generator. Essentially, it will be an EV at the front with an EV power train, and with 90% of battery replaced by a suitable MGT generator.

The MGT generators have various advantages over IC Engines. In principle, they are fuel flexible and can run on a variety of liquid and gaseous fuels including biofuels as well. They are 8 times lighter and 10 times compact than an ICE, almost zero vibration, and the noise can be easily contained with an enclosure. A suitable technology for combustion that we are introducing called Lean Direct Injection results in significantly lower pollutant emissions and with better efficiency, CO2 footprint also comes down significantly. ICE has a maintenance period of 500 hours (30,000 km) and a life of 10,000 hours (6, 00,000 km), whereas turbines will have a maintenance cycle of 10,000 hours and a life span of 40,000 hours, which is far greater than ICE.

The advantages over an EV become a mammoth when considering heavy-duty commercial vehicles that are needed to carry goods for long distances. The current limitations in the battery technology in density and range limit its usage in this vehicle segment and this is where the turbines will play a major role in the future and would be the go-to technology for this segment for many decades to come. Today, there are manufacturing methods that are available which can allow turbines to be produced in bulk and here, our LDI technology plays a major role in bringing the CapeX down for the turbine and overall for the Turbine Electric Vehicle (TEV) such that the CapEx will be at par with an ICE. Further with an electric drive train, it can give a better economy and result in OpeX almost at par with EV with CNG and diesel fuel combination. The batteries have a limited life of about 8 lakh km, whereas the Turbine can continue to go for 3-4 times. Finally, the advantage of fuel flexibility results in the capability to use diesel, petrol, CNG infrastructure, and later on, shifting to bio-ethanol, bio-diesel can be smoothly done.

Q. Are these MGTs compact enough to fit into automobiles? How would the performance be compared to an EV?

Turbines can easily fit in a vehicle as it is lighter than the ICE. As I said before at the front, it is like an EV and driven by an Electric Motor. The turbine provides the major source of power for these motors with a small battery pack that will be used for certain extra power for quick acceleration or shall get charged during braking.

Q. The main focus on EV is for its Environmental Benefits, can MGT compete with EVs in terms of air pollution?

Yes absolutely! The sector we are focusing on is heavy-duty vehicles and they are the ones which are one of the biggest culprits for pollution and the battery technology might require another 20 years globally to catchup in developed economies and perhaps much more than that for India. Hence, if we compare that to an existing ICE truck that would stay the same for the next 30-40 years, we can make leaps in reducing the emissions. We are also banking on CNG and biofuels based fuels along with electrification as part of the government plan for future energy to bring down the emissions. Here are a few numbers for your reference for a truck/bus.

w.r.t to ICE- 100 Tons of CO2; 50 Tons of CO & NOx, 10 Tons of PM reduction annually.

w.r.t to EV (considering grid with its carbon footprint) – 50 tons of CO2 annually

Q. Will MGT powered automobiles be more economical than IC Engine?

Yes, the fuel cost can come down significantly by up to 3 times with diesel and CNG mixed usage compared to ICE.

Q. Have you tested your turbines on automotive yet? What challenges do you expect in the process?

We are yet to test our turbines with a vehicle and for that, we are working closely with a few OEMs which are in the commercial vehicle segment. We would be supplying them with the machine. The challenge we might face would be in the integration of the technology with their platform. Moreover, certain challenges from the regulatory side might be there in terms of subsidy and GST rebate, etc. The turbines are cleaner than ice and should also come under subsidy. Other nations provide subsidies for vehicles with a new concept such as a hybrid. That needs to be done here as well.

Q. Fuel flexible MGTs will become the mainstream in replacing the existing DG sets for the backup power. How far is it true?

It is a plausible scenario. Turbines have been around since the 40s-50s. They have replaced the piston engines, then due to their superior reliability and performance, and with certain innovations that we are bringing in; they can certainly do the same for terrestrial applications including DG sets. The USP of the turbine lies in its fuel flexibility or ability to run low calorific value or dirty fuels such as biogas, syngas, etc. which the ICEs struggle to adapt to. Once the volume-based manufacturing is established for gas turbines using the existing cheaper materials and manufacturing standards that are used for making a turbine-like component called Turbocharger, they can compete with DG sets on various aspects which includes efficiency, reliability, emissions, etc.

Q. Your company has cut down the upfront cost of micro gas turbine generators by 10 times. How was that possible? What difficulties did you face?

Some of you may know about Turbocharger. These are similar to an MGT in terms of construction and principle. They are produced in bulk and are used with ICEs running on diesel to improve its performance. They are mass-manufactured using cheaper materials and well-established manufacturing processes. We intend to use the same process to make our MGTs and the catch here is our LDI technology which now makes it possible to use these processes for making an MGT.

We had to think from the first principle and understand why can't the gas turbines be cheaper and what stops them from being so and realized it was the exotic material selection that goes into the aviation-grade machine. But for automotive application with certain changes in our combustor region, we were successful to lower the temperatures which didn’t require us to use those exotic materials and manufacturing processes adopted for aviation-grade turbines or jet engines anymore.

Q. What are the other technologically advanced products lined up to be manufactured by your company?

The first product line that we are planning is a 120kW product range for Heavy Duty commercial vehicle applications. Later on, we will be introducing suitable products for different commercial vehicle segments with power levels ranging from 20kW to 200kW. For the gen-set market, we will be using the same products and start combining them and can offer capacity up to 1 MW for distributed power generation that uses cleaner fuels such as natural gas, biogas, or producer gas. Over time, we will be bringing further innovations in our technology for various subsystems that we are currently importing.