Over the past few years, IoT has gained immense prominence and the world is fast moving towards a connected environment. The Small Enterprises, SEMs, and OEMs that are the backbone of the economy are adopting digitally connected business methodology to add value to their business.

With the passion for industrial IoT innovations, product engineering, and business growth; Mr. Hariharan Ganesh laid the foundation of a company named Factana Computing -The Cognitive IoT Company. The main aim of starting this venture was to help SMB to attain the value of Industrial Automation by leveraging Industrial IoT. Mr. Hariharan has over 24 years of experience in the IT industry as an Enterprise Architect and BU Head.

In an interaction with Circuit Digest, Mr. Hariharan, the founder and chief architect of Factana Computing discussed the current scenario of the Indian SME and Small Enterprises, shared how the IIoT Platform and Apps (provided by Factana Computing) help in managing highly secure edge devices, gateway, and automation services across various industries.

Q. Factana is an Industrial Internet of Things (IIoT)-centered innovation company. What type of solutions and services do you offer?

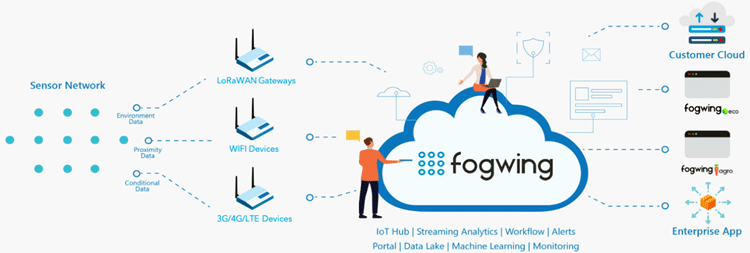

Factana’s vision and mission is to make IoT adoptable by everyone, especially for small and medium enterprises. With that vision, Factana provides the option of both “build your own IoT solution” or “Buy your IoT solutions” to all customers. Fogwing IIoT Platform is a Cloud IIoT Platform where SME and Startup companies that are interested to build their own IoT based solutions can achieve the best. Fogwing Apps are a list of prebuilt industrial IoT Apps for specific industrial use cases which can be subscribed as SaaS model. Factana helps customers to adopt end-to-end IoT solutions from industry-grade IoT devices to the user application.

Q. Tell us about the Fogwing platform and how it helps in monitoring the environment’s climate condition and controlling solution for greenhouses and other applications?

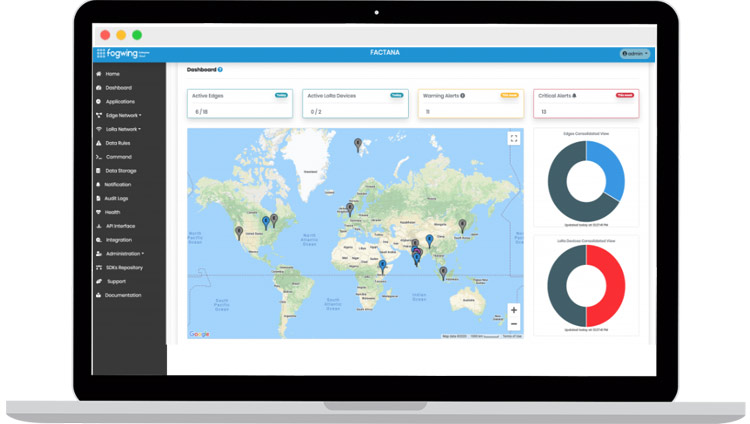

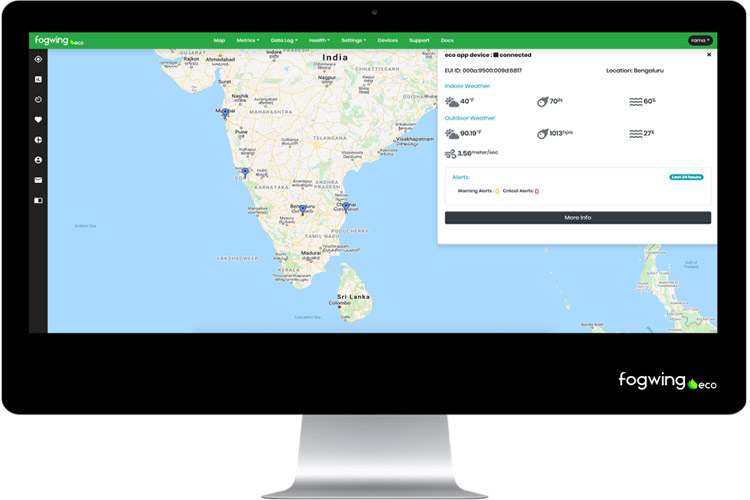

Fogwing is our Enterprise Cloud that offers an Industrial IoT Platform built to address the dynamics of industrial use cases. Industrial use cases vary from low-power IoT networks (LoRaWAN/NB-IoT) to high-speed IoT networks (4G/5G/Wi-Fi). Sometimes, it is a combination of both types of network communication required to build an automation solution. Fogwing supports both types of IoT network-based device management, data aggregation, and analytics in a single platform. Example: Monitoring environment climate condition such as greenhouse monitoring may require low-power IoT devices, but manufacturing automation use cases require a high-speed network. Fogwing IIoT Platform supports all of them.

Q. Are the IoT Sensors used in Livestock Management Manufactured by Factana?. How are these different from the others in terms of technical aspects and performance?

We at Factana do not manufacture the sensors; instead, we provide complete IoT kit to monitor environment, cold chain logistics, and agriculture use cases as part of our SaaS offer. Fogwing Eco App and Fogwing Agro App are our SaaS subscription offers that come with IoT Kit which can be just plug-and-powerup model. Our customers need not worry about IoT technologies; it is just as simple as that. Livestock management is part of our Fogwing Agro App solution.

Q. How do you compare between LoRaWAN, LTE, SigFox, and NB-IoT? Which among these will help us scale IoT solutions globally?

They are all great IoT network technologies available; however, not all of them are of a global scale. For example, LoRaWAN is broadly available in the Europe region through TTN and SigFox is the one covering the entire North America. So, we cannot leverage either LoRaWAN or SigFox as one network for the entire western region. Instead, we need to look at IoT use cases, data traffic, and network availability for each region separately, therefore, the IoT solution can be applied globally by leverage the best network available for each region. This is where Fogwing stands out as an IIoT Platform that supports all of the network management as agnostics. Our platform users can create both Cellular Network (3G/4G/LTE) and LoRaWAN network within the platform to manage the communication between these devices. In fact, our platform users can also build an integration workflow and send automated commands between Cellular IoT devices and LoRaWAN devices as the M2M model.

Q. How is your experience of working with different IoT Cloud Platforms like AWS, Google Cloud, Azure, etc? How would you compare them?

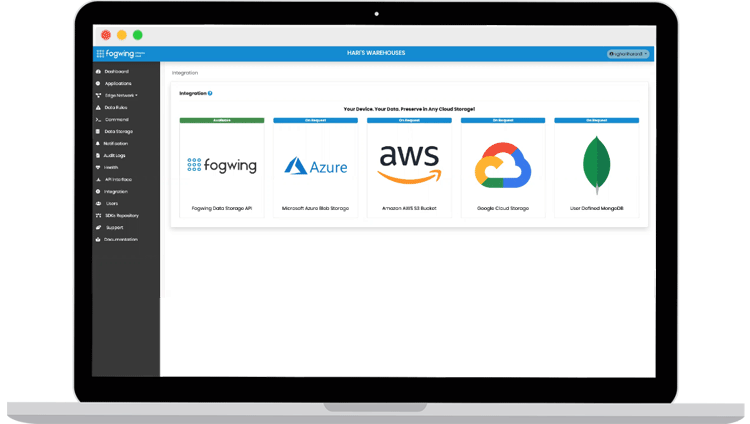

While we admire AWS, Google Cloud, and Azure IoT Platform capabilities, we strongly believe that building IoT solutions using these platforms requires significant technical skills and investment. Besides, to build the end-to-end IoT solution requires multiple cloud service subscriptions and IT efforts to glue all of them together which can be done by wealthy enterprise companies only. It cannot be affordable for startup, small, and medium enterprises. We wanted to solve this problem. As a result, we built Fogwing IIoT Platform as an all-in-one IIoT Platform. Fogwing provides all end to end capabilities (device management to analytics dashboard) required to build an IoT solution in a single no-code platform. Also, Fogwing is extremely affordable for anyone to start any type of IoT pilot project at zero cost of investment and extend as a monthly subscription basis. We also provide cloud integration capabilities for our customers to move the data from Fogwing Cloud to other Cloud Service Providers like AWS, GCS, and Azure.

Q. According to you, what are the three biggest IIoT trends affecting major industries?

According to us, we see that Industry 4.0 is the biggest trend that is affecting manufacturing and related supply chain industries within the IIoT sector. Even though IoT based home automation is something of common interest, digitalizing the manufacturing operations with Industrial IoT is going to be the biggest change ever.

Q. What is your prediction for the future of IoT in logistics and supply chain?

Logistics and supply chain play a major role in both the manufacturing and consumer market. Amazon sets the global benchmark that distribution and delivery can be transparent to customers for them to track their orders. When simple $10 books can be tracked online, why cannot my $100K manufacturing order be tracked online? It is just extending the supply chain tracking from the origin. IoT will play a major role in making this digital experience extend to logistics and manufacturing.

Q. As an IoT solution provider in India, what challenges did the company face in the early offset?

Building IoT solution is complex in nature due to the level of technology capabilities required in hardware/sensors, communication technologies, data analytics, and cloud infrastructure, etc. To build an IoT Platform or provide a solution to customers required all these technical capabilities with domain knowledge. Assembling such a broader expert team is the biggest challenge for all providers in India. However, there are great companies in India that have demonstrated it. At Factana, we want to be end-to-end IoT providers to our customers. So, we offer Industrial IoT Platform to IoT Devices as a comprehensive offering to our customers to ease their adoption of IoT.

Q. In your opinion what is the size of the industrial automation products market in India. What are its growth prospects?

The manufacturing sector is the emerging market in India and is expected to be the next manufacturing hub in the global market. With strong initiatives from the government as “Make in India”, India is expected to reach over US$1 trillion by 2025 with over 100 million job creation. However, the challenge is around manufacturing skill set and workforce capabilities which show the biggest threat to our growth. While the other side of the world is already moving into automation, we have to be equipped well to advance our capabilities in automation. We see that there is a great potential for IoT based industrial automation products, therefore, we are investing in our IIoT Platform and eFactory Application as a combo of IIoT and App in one single subscription.

Q. Please share some details about the Fogwing Industrial IoT Platform V1.6.

Fogwing is our Industrial IoT Platform available as Platform as a Service (PaaS) for the SME market on a subscription basis. Fogwing IIoT is available as Community Plan which is 100% FREE even for commercial usage. We continuously invest, innovate, and add more functions and features into our platform at no cost to our customers. Our latest release is version 1.6 with additional features such as dynamics of inbound data capturing, cloud integration, and performance improvement. This version also opened exclusive functions to our FREE users which usually are available to paid customers.

Q. Tell us something about the Fogwing eFactory App. How is it going to help manufacturing industries?

eFactory is our premium product coming soon to enable true digital manufacturing. As we know Industrial IoT is the key to transform traditional manufacturing operations into digital manufacturing by connecting, collecting, and analyzing the manufacturing performance in real-time. eFactory is the connect factory solution which will be available as a plug-play model for small and medium manufacturers to achieve digitalization. The goal is to simplify the IIoT adoption for manufacturers to just install our sensor devices, collect data, predict and automate the corrective actions. All of them are available as simply a subscription model instead of a heavy investment. We are offering 2 years FREE subscription to our beta customers. If anyone is interested to be a beta customer program, they may approach us.

Q. How do you plan to empower small and medium businesses in accelerating operations with Industrial IoT post COVID-19? Are there new products lined up that we can expect to see in the near future?

COVID-19 is a global disaster that is impacting every person and business across the world, especially small and medium businesses that are heavily impacted due to revenue losses. For them to come back to financial stability requires them to focus more on business efficiency by reducing operating costs and increasing profitability. If SMB wants to improve business efficiency, then they should know where they are lagging in the overall operations. That leads to the demand of operational visibility. We want to help SMB with Industrial IoT technologies. IoT technologies are a great tool to get real-time data from manufacturing or operating facilities. We believe that our eFactory solution will directly help the manufacturer. But other than we also have Eco App for cold chain logistics business and Agro App for farmers and industrial agriculture companies. To help them further in this crisis, we offer our environment monitoring, agriculture monitoring kits, and software platform on a rental basis further. We hope that it helps SMB at this difficult time.