Go GreenEOT (Energy of Things) is a company focused on building energy efficient technologies to power our future. Since energy plays a major role in Electric Vehicles the company started its journey with EV back in 2011 as Go GreenBOV (Battery Operated Vehicles) with an aim of proving a comfortable two-wheeler that is elegant in looks, geeky in technology and a saint on the environment. With its strong team and better understating of technology the company is confident in transforming the way energy is used or seen today. Over the years the company has launched a wide variety of Electric vehicles and has worked closely with B2C segment and now is exploring tie-ups in B2B category with an assured reduction of last mile delivery cost upto 30%. Curious to know more about the company, CircuitDigest approached Mr. Dhivik, the Founder and CEO of Go GreenEOT.

Dhivik has over 11 years of experience in building companies and have been holding the helm of Go GreenBOV for more than 9 years now. He was the only representative from India to be a part of Samsung SDI global contest and has worked over a month in the Samsung SDI plant that manufactures Lithium Cells in S.Korea. His contribution towards the Energy Storage Space over these years, has won him an award from the president of India.

Q. How has your journey with Go GreenEOT been, what is the company currently focusing on?

Our First foray into the market was in the year 2010, from 2010 to 2015 even when the Indian market had nothing much for Electric Vehicles we sold about 12,000 Electric two wheelers. At that juncture, we were using lead acid batteries because they were way more cost effective compared with lithium batteries and also lithium was beyond the scope of Indian market considering its cost and availability.

The problem with lead acid batteries were that the energy output was only about 35 Watt-hour per kilo gram, because of this the weight of the battery was high and lower sized motor were used resulting in an under powered vehicle. Now, with lithium batteries the biggest advantage is that you can generate high power with less battery weight allowing us to design high power electric vehicles.

After 2015 we were the first to change our business model from B2C to B2B because we realized that there is a market opportunity for EV 2Wheelers in India. Currently we focus on the B2B segment like the delivery companies and along the way we have also made improvements to our battery life expectancy and temperature build up problems in battery packs considerably.

Q. How do you see the market for EV in India? How would Go GreenEOT add up to it?

When I look at it, I think EV adaption in India is not going to be that very significant till 2025. Because right now, if we were to compare an EV with a Honda Activa which is available for around Rs.70,000. Activa can travel around with about 80 km/hr speed and can be easily re-fueled at multiple stations allowing us to cover more distance. Adding to that, it can also carry heavy weight and provide a good pick-up. Now when it comes to electric vehicle this is not the case, EV’s still require longer charging hours and on top of that lacks resale value compared with a conventional two wheeler.

A possible solution for this problem will be mass adaption, which results to reduction in costs and setting up of charging stations and the required infrastructure will be built. To accelerate this mass adaption is why we began with the B2B segment. These are reasons why Go GreenBOV currently concentrates more on the B2B section.

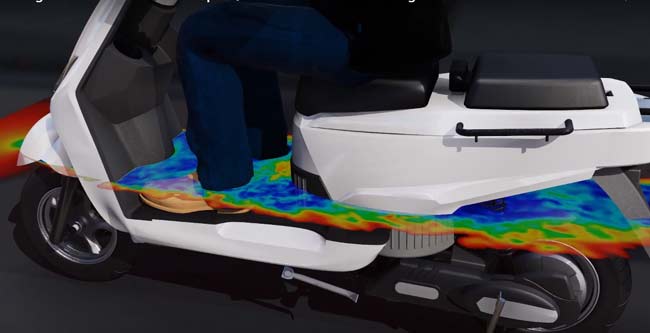

Q. Go GreenEOT has demonstrated its Battery Cooling Air Flow Technology at the CES 2019, tell us few things about it

One of the main reasons why EV users end up getting lower mileage or lower battery life is the temperature build up inside the battery packs. A good example can be given by considering an Android mobile phone. The mobile phone is optimized to perform low power consumption work like making calls, sending text messages etc, but the moment we start using it extensively like for gaming purpose you can notice the battery getting hotter and draining faster than normal. From this we can observe that battery drops much faster when it is hot.

For this Go GreenEOT has worked on a Battery cooling Air Flow technology using which we can control the temperature of the batteries. With this technology the battery temperature increase only to about 6° to 8°C when it is being discharged from 100% to 0%. This figure is much lower compared against the normal method in which the temperature rise can be upto 65°C with the delta of increase being 37°C. With this we have seen the battery life increasing by about 1.2 times with a 30% to 40% improvement in the range.

Q. Go GreenEOT is also working on Connected Technologies to monitor critical EV parameters over Internet. Tell us few things about it, what impacts will it have on consumers?

Our goal is to first make a cost effective product and then proceed with improvising and perfecting it. Finally in the end we deliver the refined product to our customers. For this refinement process, we have developed a system which could get close to 217 parameters every second from our electric vehicle using which we have been able to improvise a lot in terms of battery life, range etc.

For the Connected things we believe it’s a two Way Street in which the customer gets benefited by knowing about his vehicle while the manufacturer also gets benefited by remotely monitoring the performance of his vehicle.

Q. Being an EV manufacturer in India, how does Go GreenBOV manage its supply chain? From where does it source Electronics components and Batteries?

Establishing the supply chain was one of the biggest challenges we faced. The companies have to look at it with a very long term approach. After some research we understood that lot of components are either not available in India or priced high, hence it has to be sourced from elsewhere. Slowly we have been able to do this by working closely with our existing suppliers and discussing our designs with them. Today we have a well established supply chain including major vendors.

Q. What are your thoughts on Lithium Cell manufactures in India?

Getting the right type of cells for your EV is vital, and Go GreenBOV has invested a lot of effort and time into it. We have visited the stock yards of our suppliers and taken into consideration the temperature layout, humidifier and dehumidifier used, date of chemical studies and much more before selecting the right battery vendor for us. WE have been able to do a complete QPA of the manufacturing facility where close to around 400+ parameters are identified for long term life of the cell itself.

As far as lithium manufactures in India are considered, the on ground reality versus the off ground reality is quite harsh. The big players are talking about manufacturing Lithium cells in India but no one seems to really get into it because of low demand. Also setting up a Lithium cell manufacturing plant will take about 2 years and another 2 years to begin production which is another reason why we don’t see any solid lithium manufacturers in India yet.