Flow rate measurement involves the determination of the quantity of fluid passing through a specified surface area of a vessel at a particular time. Like all form of measurements, it has everyday life applications ranging from its use in monitoring water and gas consumption for bill estimation to more critical industrial applications (e.g large scale mixing of multiple chemicals) where the flow rate measurement plays a key role in maintaining the quality of the process/product.

To determine the flow rate, special kinds of meters referred to as flow meters are employed. There are many different types of Flowmeters, due to the diverse requirements in flow measurement (linear/non-linear, mass/volumetric rate, etc). The meters vary from one another based on different factors including; the measurement technique they apply, the specific flow parameters they monitor, the volume of fluid they can track, and their physical attributes to mention a few. The YFS201 is a popular water flow sensor, which we have previously used to measure water flow using Arduino and calculated rate of flow and volume dispersed.

Some of the types/categories of flow meters include; Turbine, Vortex, Thermal mass, Magnetic, Oval gear, Paddlewheel, Coriolis, Mass flow, Low-flow, and Ultrasonic flow meters which are the focus of this article. Ultrasonic Flow meters provide a non-invasive, very reliable means of determining the amount of fluid flowing through a vessel and they have found applications across different industries from oil and gas to Utility providers.

For this article, we will be looking at everything around the Ultrasonic Flow Meter, how they work, advantages, and disadvantages.

The Ultrasonic Flow Meter

As the name implies, the ultrasonic flow meter, one of the widely used flow meters, is a non-intrusive device that calculates the volume flow of fluid by measuring its velocity with ultrasound. It can measure fluid flow in virtually any fluid where sound waves can transmit. This type of flow meter is usually considered as “hybrid” as it can either use the Doppler principle or transit time method to measure flow, we will discuss both the principles later in this article. Do note that these flow meters are also called as Doppler flow meter if they operate using the doppler principle.

The Ultrasonic flow meters are most ideal for water applications where low-pressure drop, low maintenance, and chemical compatibility are required. They will generally not work with drinking or distilled water but are fit for wastewater applications or conductive dirty liquids. They are used with abrasive and corrosive liquids as they do not obstruct liquid flowing through the pipelines.

Working principle of the Ultrasonic Flow Meter

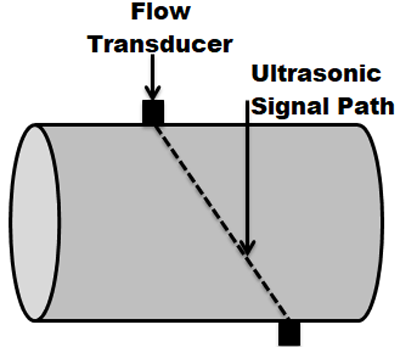

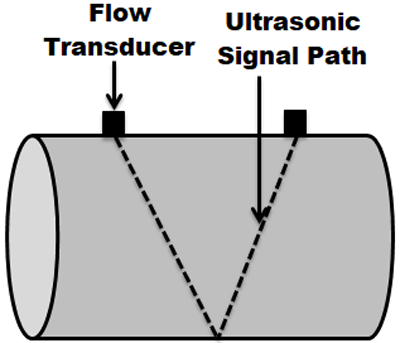

Ultrasonic flow meters use the principles of echo, and variation in the speed of sound across different mediums to measure flow. The meters typically contain two ultrasonic transducers with one acting as the transmitter and the other as the receiver. The two transducers could either be mounted side-by-side or at an angle from each other on opposite sides of the vessel. The transmitting transducer emits sound pulses from the surface of the sensor to the fluid and it’s received by the transducer designated as the receiver. The time it takes for the sound pulse to travel from the transmitter to the receiver, known as transit time, is then estimated and used in determining flow rate and other parameters.

For the second configuration, with the transmitter and receiver placed side by side, the transmitter emits the sound pulse while the receiver monitors the time it takes to receive an echo of the transmission.

Irrespective of the sensor configuration, the measurement with transit time difference is based on the fact that; sound waves propagating in the direction of flow of the medium move more quickly than the waves propagating against the direction of flow of the medium. Thus, the difference in the transit time is directly proportional to the flow velocity of the medium and this principle is used to accurately measure the volume of gases and liquids and also to derive density and viscosity.

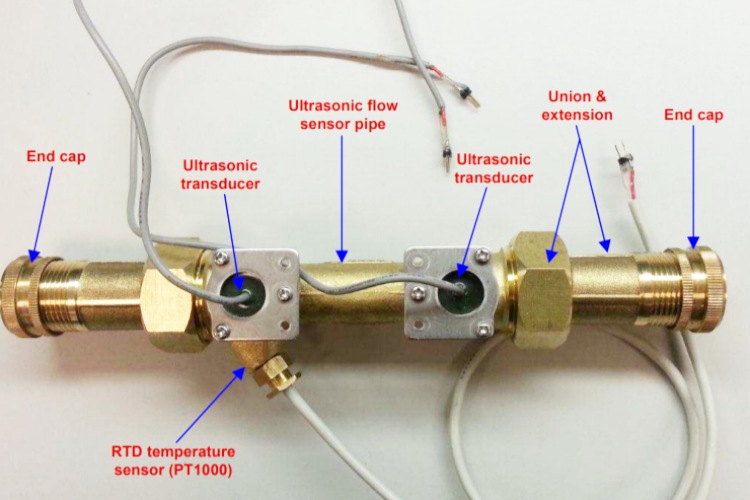

While the above two methods are the very commonly used ones, different ultrasonic flowmeters use a modified version of this, based on the type of liquid and measurement to be done. The below Ultrasonic water meter image illustrates how the upstream and downstream transducers are placed inside a sensor pipe along with some reflectors for a water flow meter design. The actual hardware set-up of the same is also shown with both the transducers marked.

Calculating Flow Rate using Ultrasonic Flow Sensors

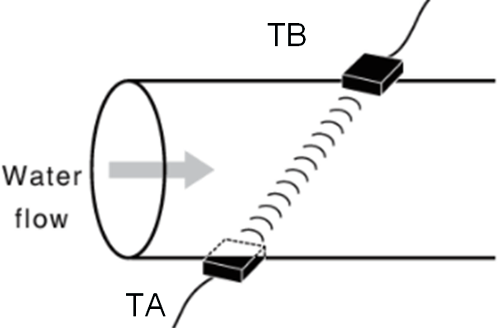

To get a clearer understanding of the technicalities behind this, consider the image below which features the first configuration with the transmitter (TA) and receiver (TB) transducers mounted at an angle opposite one another;

Let the time it takes an acoustic wave to travel from the transmitter to the receiver, that is, in the flow direction of the medium be TA –B, and the time it takes for it to move from the receiving transducer to the transmitting transducer, that is against the flow direction TB –A.

The difference in the two transit times is directly proportional to the average flow velocity, vm of the medium i.e.;

TB –A – TA –B = vm ------------- Equation 1

Since the transit time of the signal is the distance between the transmitting transducer and the receiving transmitter divided by the velocity which the acoustic signal needs to travel from one transducer to the other we have

TA –B = L / (CAB + v*cosα) -------------- Equation 2

And;

TB –A = L / (CBA – v*cos α) --------------- Equation 3

Equations 2 and 3 define the flow rate between transducer A upstream and transducer B downstream. where;

v = flow velocity of the medium, L = length of the acoustic path, c = velocity of sound in the medium, and alpha “α” is the angle to the pipe at which the ultrasonic sound travels from the transmitter to the receiver.

Assuming the velocity of sound in the medium is constant (i.e. no change in parameters like the density of fluid, temperature, etc.) we have;

(L / (2 * cos)) * (TB–A – TA–B) / (TB–A x TA–B)

multiplying the average velocity with the cross-sectional area of the pipe, we get the flow rate, Q as;

Q = (π * D3) / (4 * sin 2α) * (TB–A – TA–B) / (TB–A x TA–B)

The cross-sectional area of the pipe is constant for an inline ultrasonic flow meter with the diameter D.

The implementation of these equations without variables like density, temperature, pressure, speed of sound, and other media/fluid defined characteristics, showcases the reasons behind the versatility and accuracy of ultrasonic flow meters.

Advantages/Significance of Ultrasonic meters

The major advantages of ultrasonic flow meters have to be their non-invasive nature and their ability to work with any type of fluid (since density and speed of sound in the fluids don’t matter). Diverse substances (including chemicals, solvents, oils, etc.) with different properties are transported and distributed by piping systems every single day with the need to monitor their flow. The non-invasive nature of Ultrasonic flow meters makes them the goto meters in situations like this. This is why they find applications in different industrial sectors, from chemical-related industries to food processing, water treatment, and the oil and gas sector.

Disadvantages

The major disadvantage of ultrasonic flow meters has to be their price. Due to the complexity of their design, ultrasonic flow meters are usually more expensive than the mechanical or other types of meters, as they require more efforts and components,

Asides design complexity and cost, ultrasonic flowmeters also require a level of expertise at installation/handling compared to most other types of meters.

Top Ultrasonic Flow Meters in the Market

While the market for global ultrasonic flow meter is expected to reach USD $ 2 Billion by 2024, the market has witnessed strong growth in the past few years, thanks to its applications in numerous industries today and the introduction of some newly improved variants. Many manufacturers have developed ultrasonic flow meters with advanced technology to improve the accuracy of the measurement. As this meter caters to industry-specific solutions, the latest developments are expected to drive the market during the forecast periods. Top ultrasonic flow meters in the market include:

Sonic-View Ultrasonic Flow Meters: The sonic-view, one of the best solutions for measuring low liquid flows operates on the transit-time principle. The transducers are not in contact with the medium and there are no moving parts used within the instruments. Unbeatable features like low ownership costs, years of maintenance-free operation, protected transducers, a life-long cycle of robust meter and its insensitive nature against pressure peaks and particles, all contribute to why the sonic-view ultrasonic flow meter is one of the best solutions in the meter market.

Shmeters ultrasonic water meters: Under various pipe flow conditions, this ultrasonic water meter for industrial and commercial purposes is capable of marking design-section measurements with the highest possible measuring accuracy. The meter is battery powered and can work uninterruptedly for 10 years with only one battery; its power consumption is less than 0.5mW. It can keep working for long without being affected by magnetic interference. Meanwhile, it is highly reliable and sensitive, a flow velocity as low as 0.002m/s can be quickly detected.

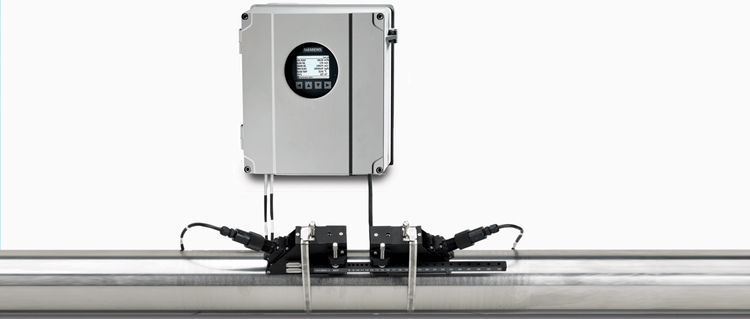

The Sitrans FS Ultrasonic Flow Meters: They deliver impressive performance for a variety of gases and liquids because they can operate independently of temperature, viscosity, conductivity, pressure, density and under the toughest conditions. The Sitrans FS220 prides itself as a best-in-class solution for straightforward flow measures as its possibilities appear to be endless.

In consumer-grade applications especially, Ultrasonic meters are becoming enhanced by technologies like LoRa which allows municipal and related authorities to monitor things like gas and water consumptions remotely. The low power nature of the communication medium enables these meters to last for 5+ years on a single battery charge, way more than what can be achieved using mechanical meters.

ماهي السافة بين متحسس على انبوب ٤انج جهاز مرسلة التدفق اسوائل