The emergence of the Internet of Things has changed various industrial operations for good. With the ability of deploying devices that could measure, record and share data we can easily create a huge database of critical data. Analysis of this database through business analytics and numeric approach provides us a better insight on what is happening in a particular process. The Internet of Things (IoT) and Big Data have enabled business managers to understand customer behaviour, improve efficiency in business operations, and understand market trends among other numerous benefits. Integration of IoT in the food sector has resulted in massive transformations. With the increasing need to maintain high food standards, integration of IoT can assist in improving food safety. Previously we talked about various IoT cloud platforms and its application in Energy sector. In this article we will explore how IoT which can enhance food safety and transform the food industry. So here are few ways for improving Food industry using IoT.

1. Enhancing Quality Assurance

According to the United States Department of Agriculture, over 20 billion pounds of food was recalled by the agency in 2018. The agency recalled these food products since they did not meet the required threshold of food safety standards. As a result, every company is struggling to ensure their supplied food meets the set standards. However, major food manufacturers using logistics agencies who might compromise the quality of their products. Many food and beverages are sensitive to temperature, and thus, reasonable control must be conducted to ensure the temperatures are maintained at the appropriate level. Failure to regulate the right temperature levels could cause food-borne diseases that might endanger the public. To eradicate the issue of unsafe food, companies are using smart thermostats to constantly monitor the temperature of the manufactured products in real-time. Real-time monitoring of the temperature means that if the temperature of the product falls below the set standard, that product is removed out of circulation to guarantee food safety. Integrated IoT systems are equipped with QR codes that customers can scan to confirm the safety of the product. This creates an assurance between the consumer and the manufacturing company that the food is safe for consumption.

2. Use of Smart Inventory Sensors

Major food sellers and distributers like Walmart store their products in warehouses. As food demand increases, these companies stock their warehouses with these food to cater for the increasing demand. One challenge arises because it is difficult to monitor the movement of each product in real-time. Keeping an inventory of these fast-moving products becomes a challenge due to the large size of these warehouses. To enhance efficiency in inventory management, companies are using pressure-sensitive sensors to monitor the stock. The sensor sends alerts when the stock runs low. Companies can further integrate Artificial Intelligence with IoT to understand consumer purchasing habits that will facilitate in future planning.

3. Use of Drones to Manage Plantations

Large plantations are integrating IoT to enhance management efficiency. One challenge in managing plantations is the need to constantly monitor and gather real-time data to understand how the crops are performing. Farmers are using drones to monitor large portions of their land and gather real-time data to enhance management. These drones capture photos and videos that help farmers identify problems early enough for action. The drones are also fitted with sensors to gather weather data that’s further analysed to give insights of how the crops are performing. IoT also helps in Smart Irrigation System where the crops are watered automatically by sensing the soil moisture.

4. Automation

Efficiency is very crucial when managing plantations. Farmers strive to cut down on operational cost and maximise profits. Currently, farmers are adopting autonomous tractors to save down on operational cost. Autonomous tractors are rarely affected by weather and mainly operate for long hours, unlike human-operated tractors. Autonomous tractors are fitted with auto-steering systems that facilitate control and performance even when there is low visibility. Self-driving tractors have high accuracy when planting seeds. This high accuracy eliminates human errors leading to increased ROI. The autonomous tractors can be fitted with advanced sensors and GPRS systems. These sensors and GPRS systems can offer services like gathering moisture data, give info regarding the planting and harvesting progress, and provide details regarding the current yield. The autonomous tractors save approximately 50% of the labor cost.

IoT has also helped in automating inventory keeping. Smart sensors are fitted in the shelves where they send alerts when the stock of a commodity goes below a particular level. IoT has also helped to automate the process of regulating temperatures in warehouses, which helps to keep the food safe.

5. IoT has Enhanced Precision Farming

Precision farming is a new idea adopted by farmers that involves using digital tools to identify and determine the exact parameters needed to increase productivity. Farmers are using these digital tools to gather meteorological data and other factors that affect crop productivity. The gathered data helps farmers identify trends that help to predict and plan. Use of IoT has helped farmers avoid making losses in the wake of adverse climate change.

6. Collaboration between Food and Agricultural Stakeholders

The success of the farming sector depends on the effective policies made by the stakeholders. These policies rely on the data gathered from the farmers and the field. IoT has facilitated the collection of factual data that stakeholders can count on and make informed decisions. Data from the farms helps farm input manufacturers to manufacture the appropriate farm inputs using the required quantities based on existing environmental factors. Also, the farm input manufacturers benefit from data gathered by food inspectorate agencies. IoT has facilitated the efficient collection and sharing of data among the relevant stakeholders. Easy access to data will help in making sound food policies to enhance food safety.

7. Supply Chain Transparency

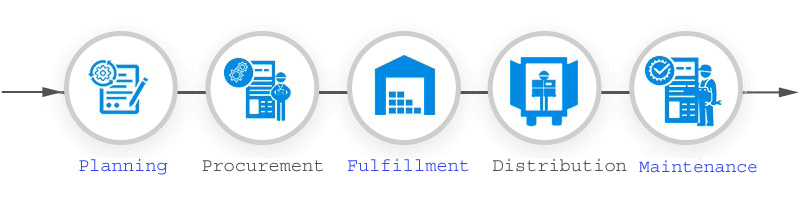

Food agencies should enhance transparency in the food handling process. Majority of multinational corporations import food from various countries. Enhancing transparency and traceability increases customer confidence and trust. With the increase in demand for organic farm produce, companies can increase customer trust by using RFID tags to enable buyers to trace the origin of the product. Transparency further facilitates inventory management, reduction of operational cost, and faster leads times. IoT helps to reveal laxity in the supply chain process, which allows manufacturers to make the appropriate changes to meet the required standards.

8. Improved Food safety

The Food Safety Modernization Act was enacted in 2011 to help enhance food safety in the United States. This act set the required policies and standards needed to facilitate compliance by chain suppliers in the quest to enhance food safety. One way that IoT is facilitating companies to achieve compliance is through the integration of real-time temperature monitoring sensors to facilitate cold chain management. The food supply chain companies can utilize IoT technology to comply with the set global food safety regulations. Food manufacturing and processing companies can use IoT technology to ensure they become compliant with the Hazard Analysis and Critical Control Points (HACCP).

9. Enhanced Operational Efficiency

Currently, 90% of significant industries have invested in IoT and big data analytics. Utilization of smart technology can enhance supply chain profitability. Smart technologies have facilitated predictive maintenance and efficient tracking of inventory. Smart technologies assist in providing real-time actionable data. As a result, supply chains are utilizing sensors to track food temperature, enhancing food safety, and reducing food losses. The smart sensor is enhancing operational efficiency by automating the process of food quality reporting.